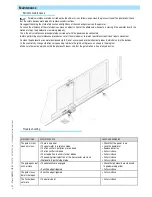

Maintenance

Periodic maintenance

Periodic maintenance to be carried out by the end-user is as follows: wipe clean the glass surface of the photocells; check

that the safety devices work properly; remove any obstructions.

We suggest checking the state of lubrication and tightness of the anchoring screws on the operator.

-To check the efficiency of the safety devices, move an object in front of the photocells when gate is closing. If the operator inverts the

motion or stops, the photocells are working properly.

This is the only maintenance procedure to be carried out with the power source connected.

-Before performing any maintenance procedures, cut off the main power, to prevent possible accidents due to gate movement.

-To clean the photocells use a water dampened cloth. Do not use solvents or other chemical products which may ruin the devices.

-In the event of any strange vibrations or squeaking, lubricate the joints with grease, as shown in the diagram.

-Make sure there are no plants within the photocell’s beam, and that the gate motion is free of any obstacles.

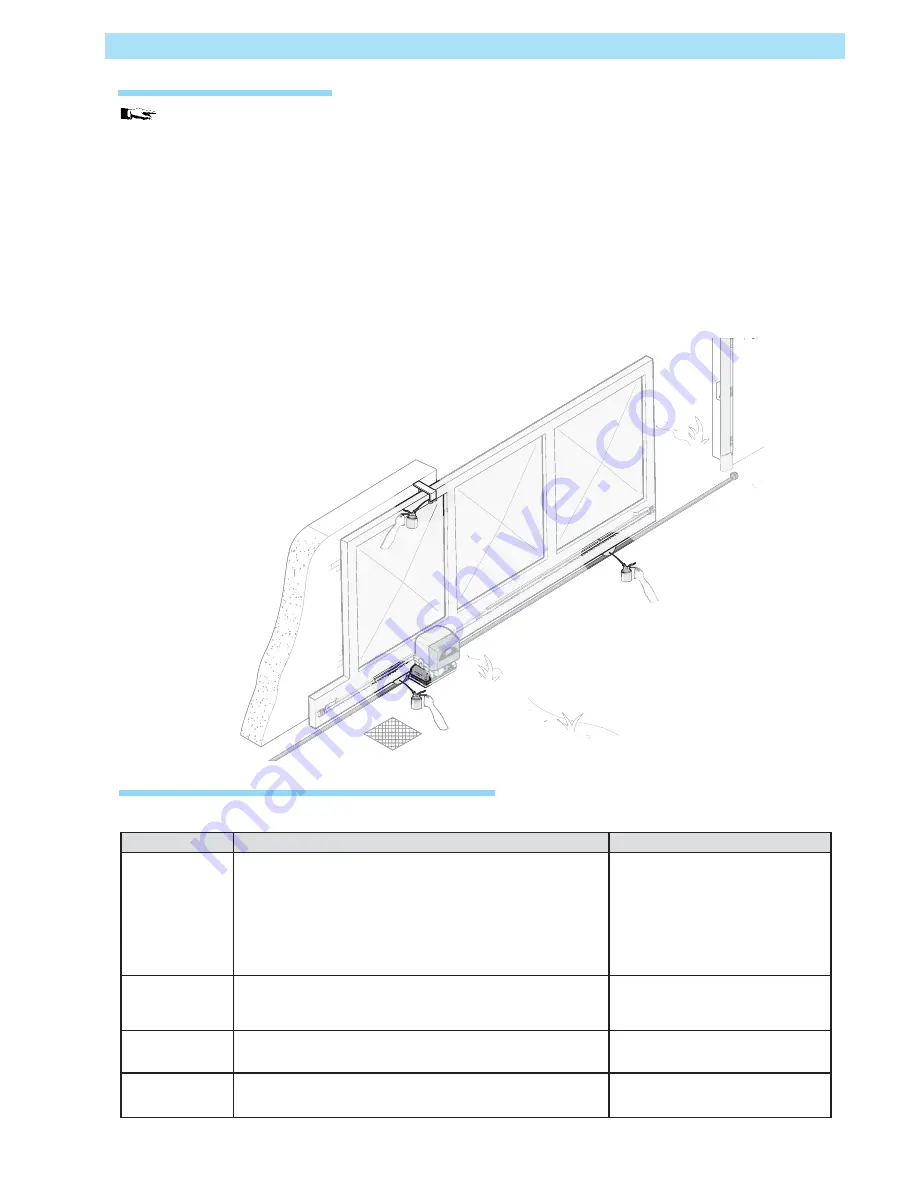

Trouble shooting

MALFUNCTIONS

POSSIBLE CAUSES

CHECK AND REMEDIES

The gate will not

open nor close

• There is no power

• The gearmotor is in release mode

• The transmitter’s batteries are run down

• The transmitter is broken

• The stop button is either stuck or broken

• The opening/closing button or the key selector are stuck

•

Fhotocells in partial stop mode

• Check that the power is up

• Lock the gearmotor

• Replace batteries

• Call assistance

• Call assistance

• Call assistance

• Call assistance

The gate opens but

will not close

• The photocells are engaged

• Sensitive edge triggered

• Check that photocells are clean and

in good working order

• Call assistance

The gate closes

but will not open

• Sensitive edge triggered

• Call assistance

The flasher does

not work

• The bulb is burnt

• Call assistance

p.

31

- M

anu

al

FA

0

1

1

3

7

-E

N

- 0

4

/2

0

18 - © C

A

M

E S

.p

.A

. - T

ransla

te

d o

riginal inst

ru

ct

io

ns