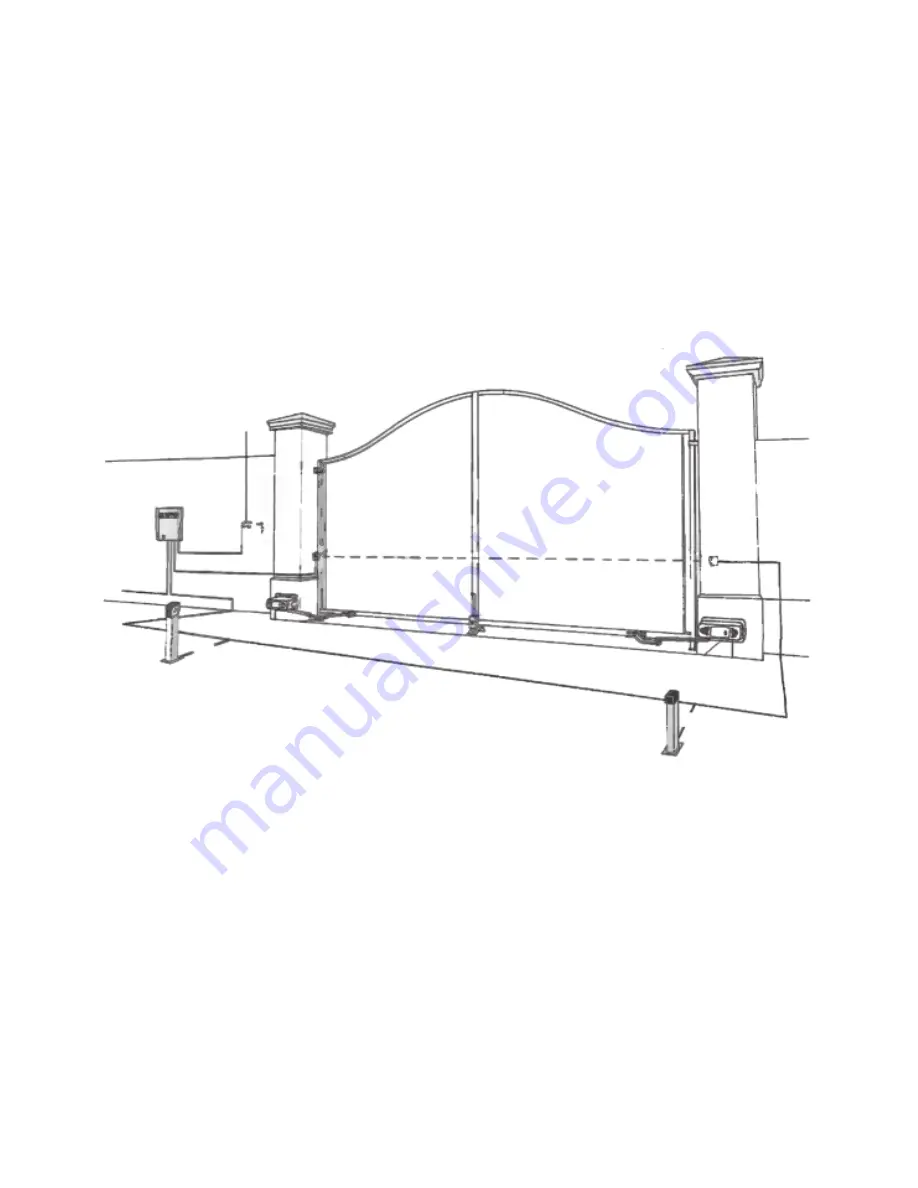

THESE INSTRUCTIONS WILL SHOW YOU HOW TO INSTALL

A FERNI GATE KIT TO A PAIR OF GATES.

PLEASE READ THESE INSTRUCTIONS AND DIAGRAMS

CAREFULLY BEFORE STARTING ANY WORK.

1

UNDER NO CIRCUMSTANCES SHOULD THIS EQUIPMENT BE OPERATED UNLESS FITTED TO A GATE.

FAILURE TO COMPLY WILL INVALIDATE THE GUARANTEE.

I N T R O D U C T I O N

Summary of Contents for Ferni Series

Page 34: ......

Page 35: ...NOTES...