FA00150-EN v.7 - 06/2017

11

CAME S.p.A.

5. ASSEMBLY PROCEDURE OF THE AUTOMATION

The FLUO-SL automations should be assembled by qualified personnel, and can be done at the factory or directly at the place

of installation of the door. After size cutting all aluminium profiles and gaskets (as indicated in the chapter 4.4), we proceed

with the automation and internal components assembly.

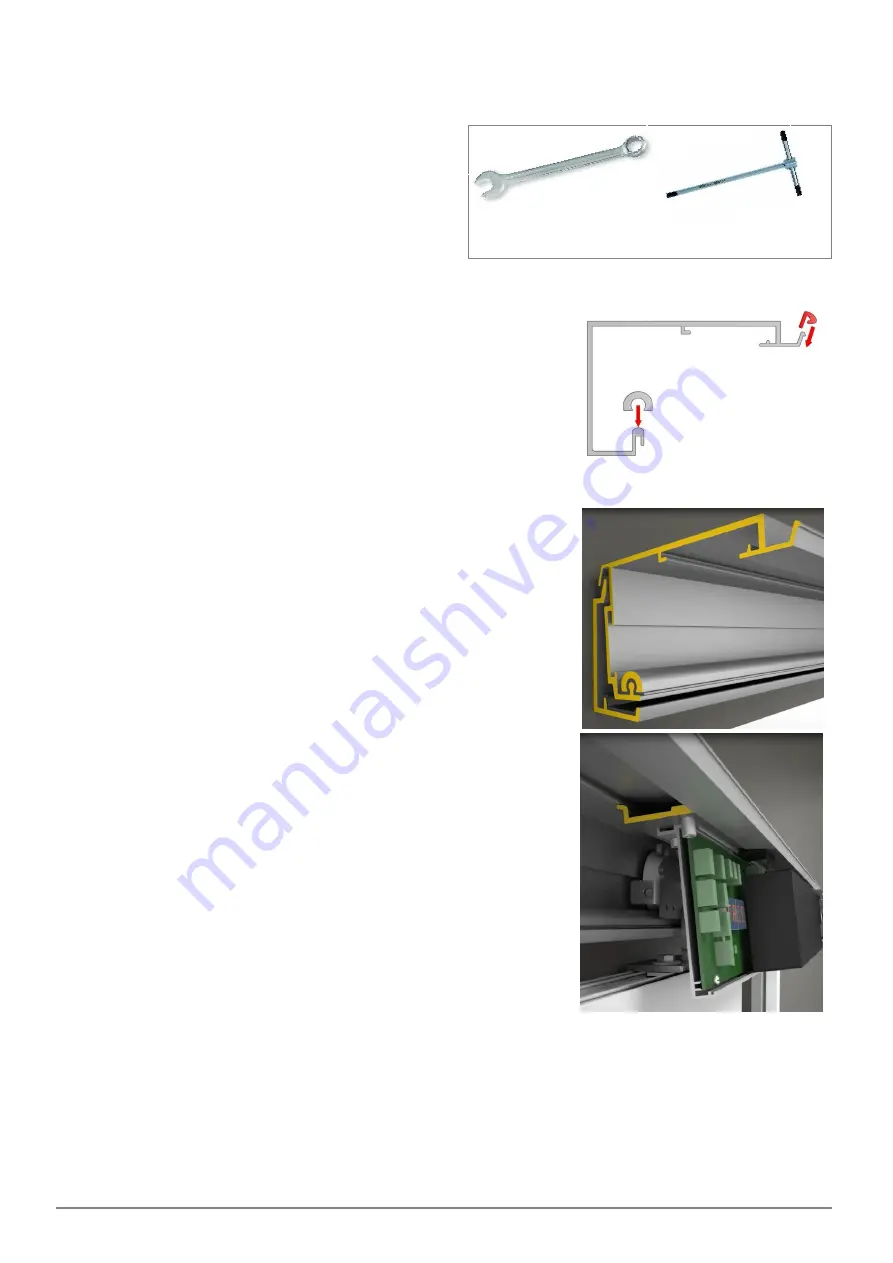

For assembly operations, in addition to the usual generic tools

such as scissors, pliers, screwdrivers, only two tools are used:

- Combination spanner 13mm

- Allen key 4 mm

5.1 ASSEMBLY OF FLUO-SLB DRIVE UNIT

- Insert the rail profile [104] in the drive unit profile [311].

- Insert the cover gasket [107D] on the drive unit profile [311].

- Insert the right and the left end caps on the drive unit profile [311], and secure

them with the screws.

5.2 ASSEMBLY OF FLUO-SL DRIVE UNIT

- Insert the gasket rail [107A] in the profile rail. [104]

- Thread by slide, the profile rail and seal in the drive unit profile [101].

- Insert the support gasket [107C] in the upper part of the support profile [100].

- Insert the drive unit gasket [107B] at the bottom of the support profile [100].

- Attach the drive unit profile [101] on the support profile [100].

- Insert the cover gasket [107D] on the drive unit profile [101].

- Insert the right and the left end caps on profiles (already assembled), and secure

them with the screws.

5.3 Secure by front hooking the drive unit on the drive unit profile, placed at a

maximum B (as shown in Chapter 4), and secure it with the screws (Note: if there

is space, it’s better to reduce measure B few centimetres).

CAUTION: If the front hooking of the drive unit is difficult, check the following:

- Check that the 3 screws of the drive unit are loose, so as not to hinder the

hooking;

- Check that the drive unit profile [101] is fixed on a flat surface;

- Loosen the 2 screws of the electronic control, in order to facilitate the hooking

of the drive unit. Upon completion, tighten the 2 screws of the electronic control.

FLUO-SLB Automation

FLUO-SL Automation