- pag.

- pag.

- pag.

- pag.

- pag.

5

5

5

5

5

- english -

- english -

- english -

- english -

- english -

DESCRIPTION OF ASSEMBLY PROCEDURE

DESCRIPTION OF ASSEMBLY PROCEDURE

DESCRIPTION OF ASSEMBLY PROCEDURE

DESCRIPTION OF ASSEMBLY PROCEDURE

DESCRIPTION OF ASSEMBLY PROCEDURE

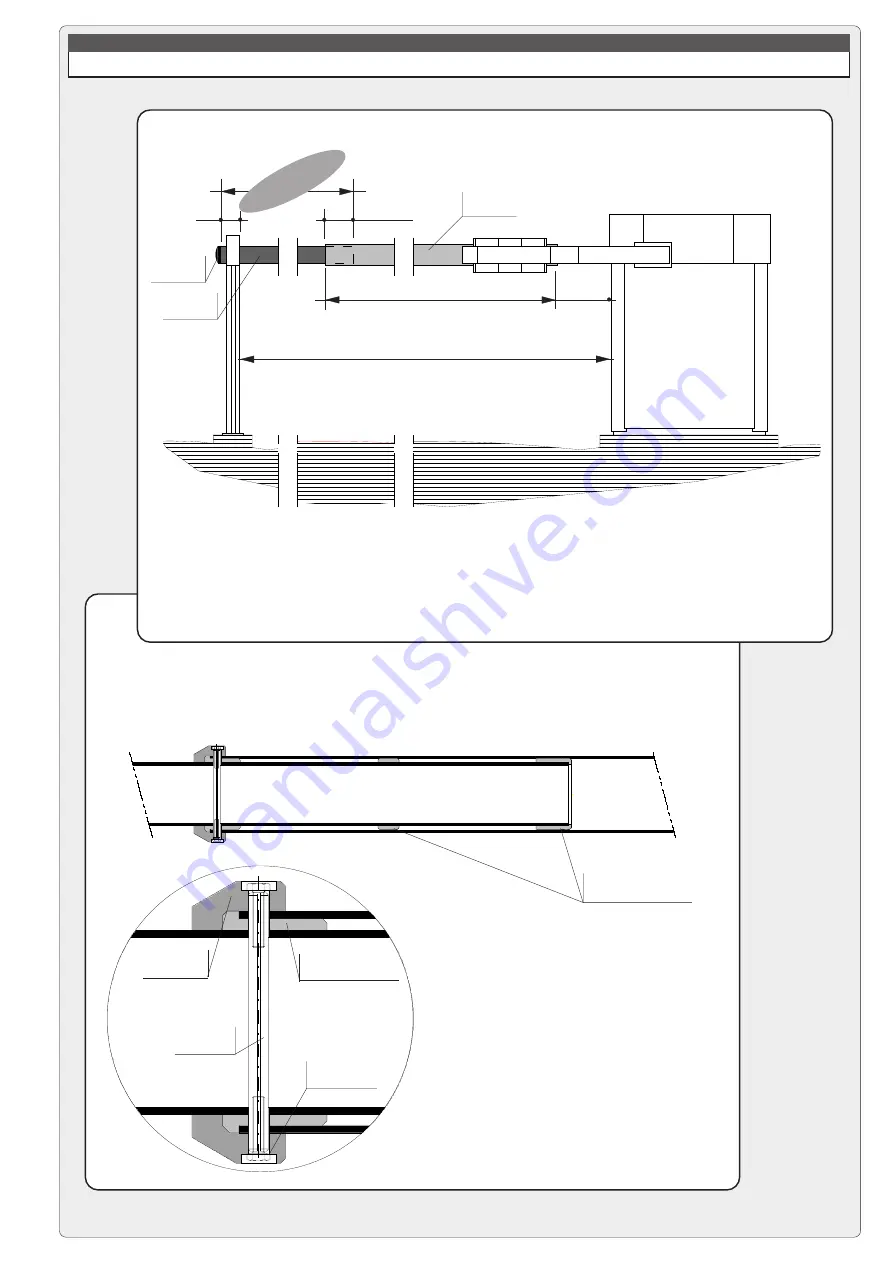

2 - PRELIMINARY ASSEMBLY OF THE BARRIER BAR

a) use the indicated formula to determine length LTP of the rear tube

(Ø100 mm), cut the tube to the correct length and install the end cap.

fixed length 6200 mm

d

epth of

insertion

b) assemble the barrier bar by

sliding the rear tube into the front

tube (Ø120 mm, fixed length of 6200

mm) and inserting the centring pin;

next, install and tighten the two

mounting jaws;

150

500

L

N

300

FRONT TUBE

REAR TUBE

END CAP

L

TP

= L

N

- 5850

mounting screw

on mounting jaw

mounting jaw

centring pin

thrust ring to be latched

onto the centring pin

FRONT TUBE

REAR TUBE

thrust rings already installed on

Ø100 mm rear tube