- pag.

- pag.

- pag.

- pag.

- pag.

8

8

8

8

8

- english -

- english -

- english -

- english -

- english -

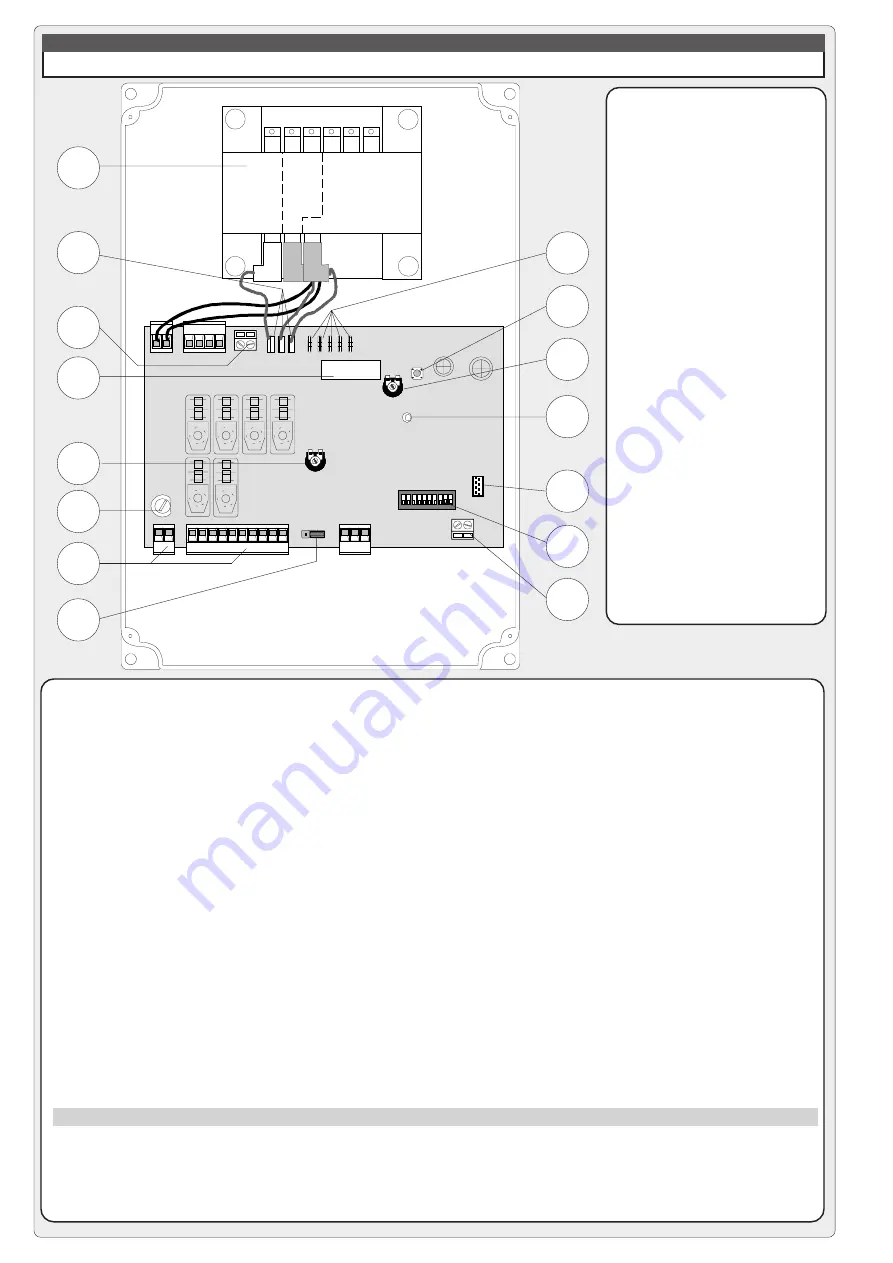

MAIN COMPONENTS

1) Transformer

2) Connectors for power

supply motor

3) Terminal block for motor

connections

4) 2A accessories fuse

5) Amperometric sensitivity

adjustment (trimmer

SENS)

6) 3,15A line fuse

7) Terminal block for external

connections

8) Jumper for selection of

type of control for button

in 2-7

9) Connectors for connection

to battery charger LB35

10) Button for memorizing

code numebers

11) Automatic closing time

adjustment (trimmer TCA)

12) Radio code / automatic

closing signal LED

13) Radiofrequency board

socket (see table pag. 11)

14) "Funcion selection" dip-

switch

15) Terminal block for antenna

connections

DESCRIPTION & CONTROL LOGIC

ZL37B CONTROL PANEL

This control board is powered by

230V a.c. across terminals L1 and

L2, and is protected by a 3.15A fuse

on the main power line.

Control systems are (24) powered by

low voltage and protected with by a

2A fuse.

The total power consumption of 24V

accessories must not exceed 40 W.

Safety

Photocells can be connected to

obtain:

a)

Re-opening during the closing

cycle;

b)

Total stop: the movement of the bar

is interrupted, and the automatic

closure cycle is disactivated. Use the

keyboard or the radio transmitter to

resume movement of the bar;

c)

Immediate closure (the bar is

lowered automatically after the

vehicle has passed the safety

devices, on the terminals 2-C5 of the

control panel;

- Amperometric safety device: see

NOTE;

- Fixed operating time of 20 sec.

Accessories which can be

connected to this unit

- LB35 board, used to power the

automation system using battery

power in case of a power failure. When

the power supply is restored, the

batteries are recharged automatically

(refer to instruction sheet);

- Flashing signal light when bar is in

motion;

- Plug-in radio receiver.

Other functions available

- Automatic closing: The automatic

closing timer is automatically activated

at the end of the opening cycle. The

preset, adjustable automatic closing

time is automatically interrupted by the

activation of any safety system, and

is deactivated after a total stop

command or in case of power failure;

- Obstacle detection: When the motor

is stopped (bar is closed, open or half-

open after an emergency stop

command), the transmitter and the

control pushbutton will be deactivated

if an obstacle is detected by one of the

safety devices (for example, the

photocells);

- “Human presence” operation;

- Flashing light activated before

opening and closing cycle begins;

- Activation of a 24V output signal

during the movement phases and in

the closed position;

- "Slave" operation when two motors

are used in combination (see page

15);

- Function that increases the braking

action on the barrier;

- Selection of command sequence:

-open-close-reverse;

-open only.

Adjustments

- Trimmer TCA = Automatic closing

time: 0" to 120";

- Trimmer SENS = Sensitivity of

amperometric safety system: min/

max.

Important

: Shut off the mains power

and disconnect the batteries before

servicing the inside of the unit.

When an obstacle is encountered, the amperometric locking device intervenes as follows:

a) if in the aperture phase, the bar stops;

b) if in the closure phase, the movement of the bar is reversed.

N.B.: In situation (b), if an obstacle is detected three times, the bar stops during aperture, and automatic closure is

disactivated.

Use the keyboard or the radio transmitter to resume movement of the bar.

NOTA

2

1

3

4

5

6

7

8

9 10

0

Rall.

Vel.

7

4

C

O

M

Velocità

Speed

Vitesse

Geschw.

Velocidad

Rallentamento

Deceleration

Ralentissement

Geschw.

Abnahme

Deceleración

"B"

"A"

2

4

1

6

7

8

14

13

12

11

15

10

9

3

5