p.

10

- M

anu

al

FA0

158

1-

EN

-

03

/2

02

1 - © C

AM

E Ö

ZA

K. - T

ra

ns

la

tio

n o

f t

he o

rig

in

al i

ns

tru

ct

io

ns - T

he c

on

te

nt

s o

f t

hi

s m

anu

al m

ay c

ha

ng

e, a

t a

ny t

ime

, a

nd wi

th

ou

t n

ot

ic

e.

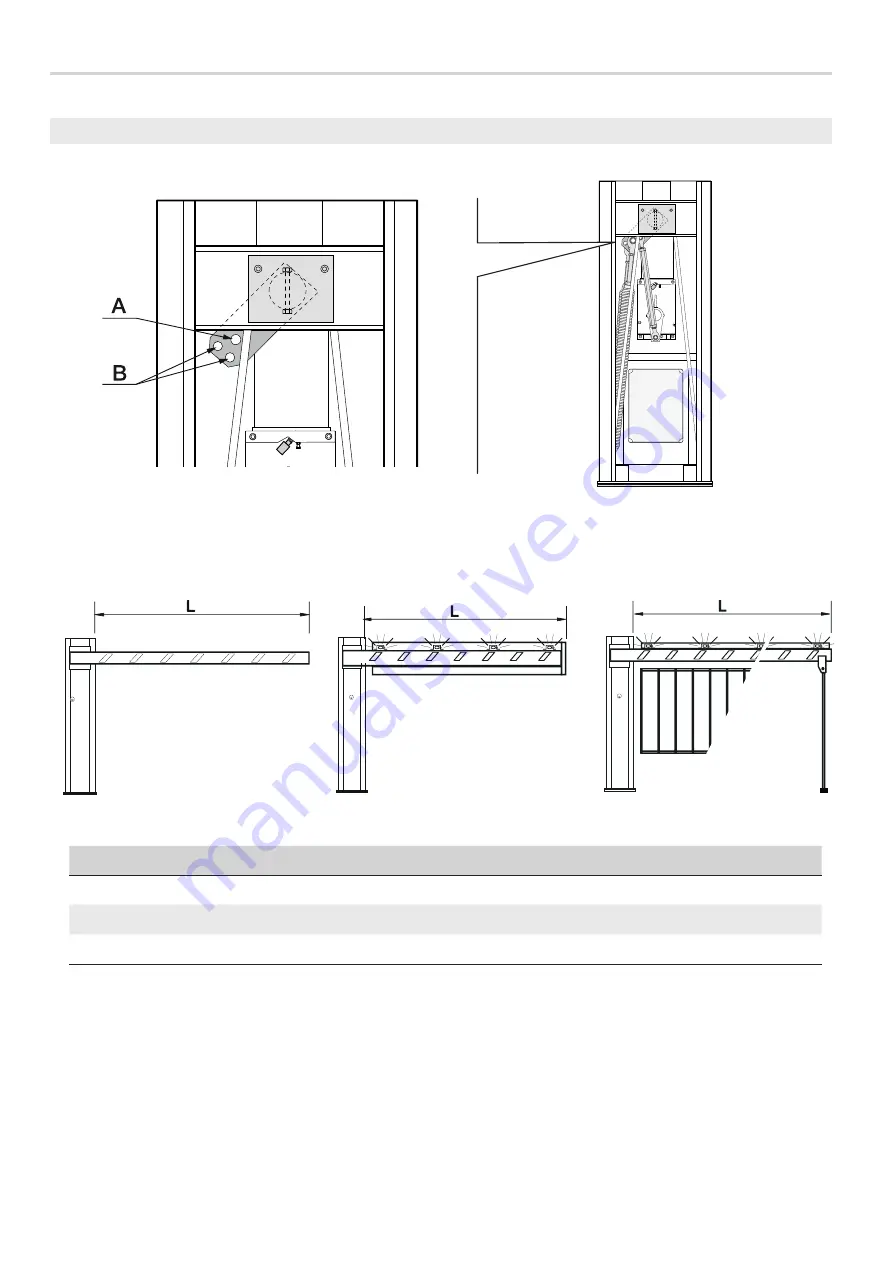

L = LATERAL CLEARANCE (m)

3 ÷ 4

4 ÷ 5

5 ÷ 6

6 ÷ 6.5

Boom

A

A

B

AB

Boom with the 001G0460 warning lights

A

B

AB

-

Boom with the 001G0465 warning lights and skirt or the 001G02808 swing leg

B

AB

BB

-

Boom with warning lights

Boom

Boom with warning lights and skirt

or swing leg

BALANCING THE BOOM

The barrier is supplied with two Ø 50 mm springs (001G04060). The springs attach to lever arm (in the B-holes).

Depending on how the barrier is finally configured, you may need to exclude one of the two springs or reattach it (see the table below).

⚠

When configuring the barrier, make sure the gearmotor is locked!

⚠

WARNINGS!

The 001G02802 cannot be used on barriers fitted with the 001G0465 skirt or 001G02808 swing rest

The 001G02807 MUST be used with passage widths exceeding 3 m.

The 001G0465 and 001G02808 cannot be used together.

Summary of Contents for G6000T

Page 2: ...2 1...