P

age

8

- Manual

FA01384-EN

- 03/2021 - © C

AME S.p.A. - The contents of this manual may be changed at any time and without notice. - T

ranslation of the o

riginal instructions

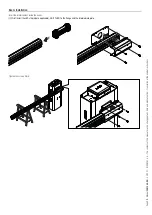

Size

482

1222

913

max. 7800

381

249

73

116

416

Cable types and minimum thicknesses

Cable length (m)

up to 20

from 20 to 30

Power supply 230 V AC

3G x 1.5 mm²

3G x 2.5 mm²

Power supply 120 V AC

3G x 1.5 mm²

3G x 2.5 mm²

24 V AC/DC flashing beacon

2 x 1 mm²

2 x 1 mm²

TX Photocells

2 x 0.5 mm²

2 x 0.5 mm²

RX photocells

4 x 0.5 mm²

4 x 0.5 mm²

24 V DC electric lock

2 x 1 mm²

2 x 1 mm²

Command and control devices

*no. x 0.5 mm²

*no. x 0.5 mm²

* no. = see product assembly instructions - Warning: the cable cross-section is indicative and varies according to the motor power and cable length.

To connect the antenna, use RG58 cable (up to 5 m).

For installation in an outdoor environment, use cables with properties at least equivalent to those of type H05RN-F (with designation 60245 IEC 57).

For installation in an indoor environment, use cables with properties at least equivalent to those of type H05VV-F (designation to 60227 IEC 53).

If the cable lengths differ from those specified in the table, define the cable cross-sections according to the actual power draw of the connected devices and in

line with regulation CEI EN 60204-1.

For multiple, sequential loads along the same line, recalculate the values in the table according to the actual power draw and distances. For information on

connecting products not covered in this manual, please see the documentation accompanying the products themselves.

For paired and CRP connection, use a UTP CAT5 cable. Maximum length 1000 metres.

Single branch length (m)

max. 50 m

BUS cable

2 x 0.5 mm²

The total length of all branches can be a maximum of 150 m.

The cable cannot be shielded.

Wind resistance

The table shows the boom wind-load resistance.

The value relates to the boom only and does not refer to any applicable accessories.

Resistance class with reference to the EN 13241 standard.

Type

Boom 4.4 m

Boom 6.4 m

Boom 8 m

Resistance class

4

3

2

Wind pressure [Pa]

1100

600

400

Maximum wind speed [km/h]

160

120

100