page

6

- Manual

FA01260-IT

- 10/2018 - © CAME S.p.A. - The contents of this manual may be changed, at any time, and without notice

. - T

ranslation of the original instructions

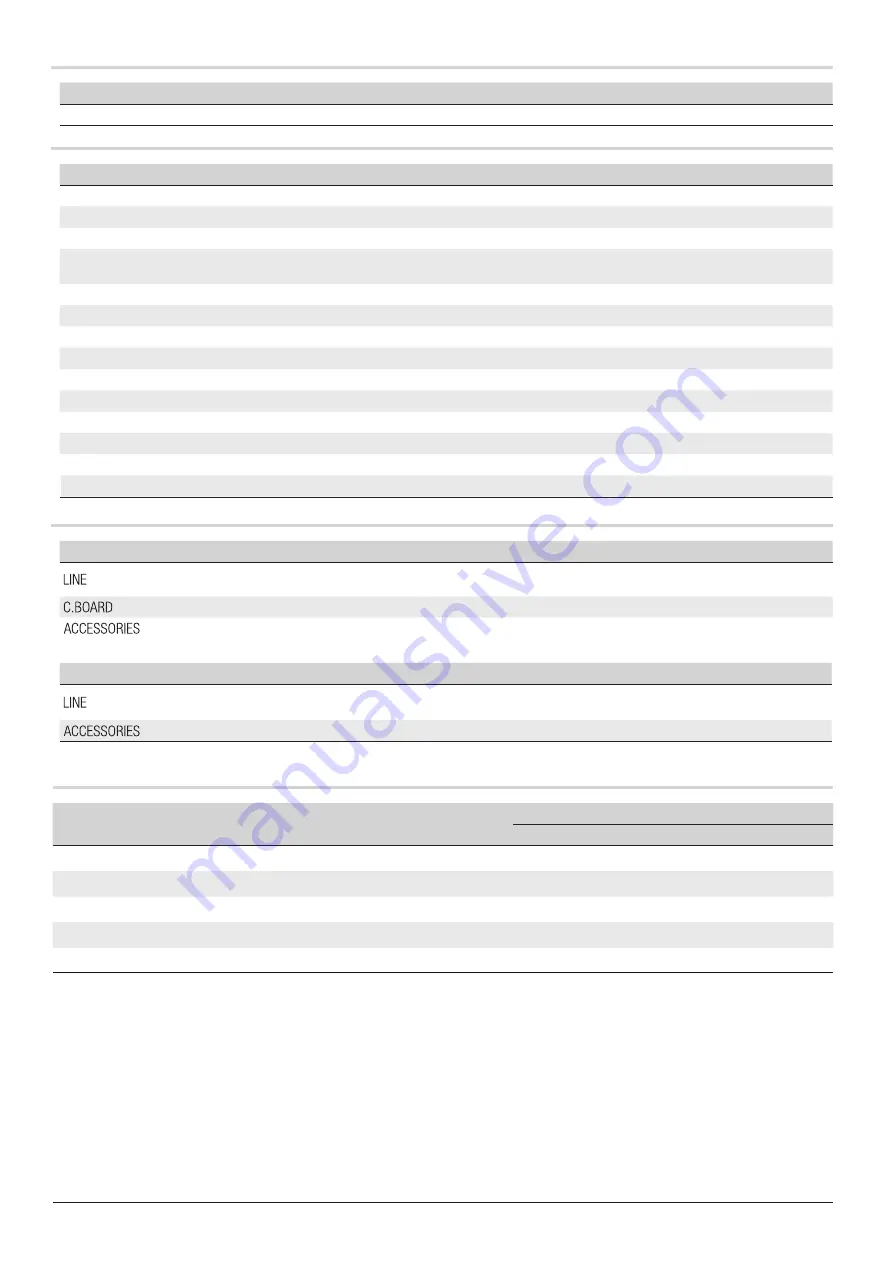

Fuse table

FUSES

ZL39

- Line

3.15 A-F = 120 V

1.6 A-F = 230 V

- Card

1 A-F

- Accessories

2 A-F

FUSES

IO-RS485

- Line

200 mA

- Accessories

200 mA

Technical data

Type

I1PB0500026 - I1PB0500027 - I1PB0500028

Protection rating (IP)

54 series

Power supply (V - 50/60 Hz)

230 AC

Motor power supply (V)

24 DC

Max draw (A)

15 (24 V)

1.3 (230 V)

Stand-by consumption (W)

8 series

Consumption with Sleep Mode (W)

5 series

Power (W)

300 series

Torque (Nm)

600 series

Opening time at 90° (s)

2 to 6

Duty cycle

CONTINUOUS SERVICES

Operating temperature (°C)

-20 to +55

Reduction ratio (i)

1/202

Insulation class

I

Weight (kg)

55 series

Limits to use

Type

I1PB0500026 - I1PB0500027 - I1PB0500028

Maximum clearance width of the passage (m)

4 series

Cable types and minimum thicknesses

Connection

cable length

< 20 m

20 < 30 m

Input voltage for 230 V AC control board (1P+N+PE)

3G x 1.5 mm

2

3G x 2.5 mm

2

Flashing light

2 x 0.5 mm

2

Command and control devices

2 x 0.5 mm

2

TX Photocells

2 x 0.5 mm

2

RX photocells

4 x 0.5 mm

2

When operating at 230 V and outdoors, use H05RN-F-type cables that are 60245 IEC 57 (IEC) compliant; whereas indoors,

use H05VV-F-type

cables that are 60227 IEC 53 (IEC) compliant. For power supplies up to 48 V, you can use FROR 20-22 II-type cables that

comply with EN 50267-2-1 (CEI).

To connect the antenna, use the RG58 (we suggest up to 5 m).

For combined connection and CRP, use a UTP CAT5-type cable (up to 1,000 m long).

If cable lengths differ from those specified in the table, establish the cable sections depending on the actual power draw of the

connected devic

es and according to the provisions of regulation CEI EN 60204-1.

F

or multiple, sequential loads along the same line, the dimensions on the table need to be recalculated according to the actual power draw

and distances. For connecting products that are not contemplated in this manual, see the literature accompanying said products

Summary of Contents for I1PB0500026

Page 2: ...4 4...