SERIE

RODEO

17

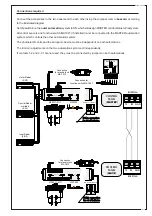

STARTING UP THE SYSTEM

VERIFICHE PRELIMINARI

Before start-up, make sure that:

✔

The electric lock (if installed) has been manually released;

✔

The proper tension has been applied to the belt (see p. 12);

✔

The checks described on p. 13 (checking for proper assembly) have been performed;

✔

No objects are present along the path taken by the door wings as they move;

✔

All mounting hardware has been properly tightened;

✔

The sensors are correctly aligned and are not blocked;

✔

The desired functions have been correctly selected on the dip switches (see p. 16);

✔

The trimmers have been set to their midpoints (see p. 15),

START-UP/CALIBRATION

1. Turn on the power to the unit

- LED no. 3 will light up

2. Move dip switch 1 to ON

- LED no. 3 will turn off and LED no. 8 will light up

- The system will execute an closing and opening cycle at reduced speed and will stop at the maximum open

position

(1)

at the end of the cycle

- LEDs no. 6-7-8 will light up

3. Move dip switch 1 to OFF

- LEDs no. 6-7-8 will turn off and LED no. 3 will light up

4. Make sure that function switch MA7041 (if installed) has been set to the “open” position (with the LEDs lit in

sequence)

5. Enter an "open" command on 2-R1/2-R2 or by pressing the open key (see p.15).

-the automation will position itself at the closing point

6. Send an opening signal

-

-the automation will perform a complete manoeuvre

7. Adjust the movement of the doors using the door trimmers (see p.15).

8. Adjust trimmer 3 to obtain the desired delay before automatic closing

9. Trimmer 2 can be adjusted only if function switch MA7041 has been installed and if this switch has been set

to the “partial opening” position

10. Use the lever on the manual release system to re-arm the electric lock (if installed)

(

1)

If the automation system stops during the closing cycle, the motor polarity may be incorrect. If this occurs, proceed as

follows:

-

Disconnect the mains power

-

Make sure dip switch 1 is set to OFF

-

Reverse connections M-N on the terminal board for the motor, which is located in the electrical

cabinet (on the right)

-

Begin another start-up/calibration procedure starting from point 1.

SAFETY FUNCTIONS - Actions taken by the automation system when a safety device trips

When the safety sensor detects an obstacle, the microprocessor control system in the electrical cabinet

actuates:

re-opening,

if the automation system is closing;

a stop,

if the automation system is opening. The system will then re-close when

actuated by the automatic closing timer.

If the obstacle is still detected:

during closing

the automation will automatically try 4 times to close the doors, and then it

will stop them in the open position, awaiting a new command.

during opening

the automation system will stop with the door wings resting against the

obstacle and will re-close when actuated by the automatic closing timer.

The system will attempt to open the door three times, and then pause with

the door wings resting against the obstacle until another command is given;

(In both cases, normal operation with the programmed settings will automatically resume when the

obstacle is removed )

Changing the direction of door opening (Rodeo 1)

- With the door stopped, reverse connections M-N on the terminal board for the motor, which is located in the

electrical cabinet (on the right);

- Re-align electric lock MA7012.

- Press the RESET key on the electrical cabinet (if the unit has already been calibrated, the relative settings

will be deleted).

- Start up (or restart) the automation system as described in the section on start-up.