21

Model 289A Differential Pressure Indicating Switch

Section 3

4. Advance the plunger screw until the switch actuates, then advance the

plunger screw an additional 60° (one flat).

5. Exercise the switch roller up and down the cam to verify consistent on/

off operation. Advance the stop screw to touch the switch, then back out

the screw 1.5 turns (9 flats).

Calibration Procedure

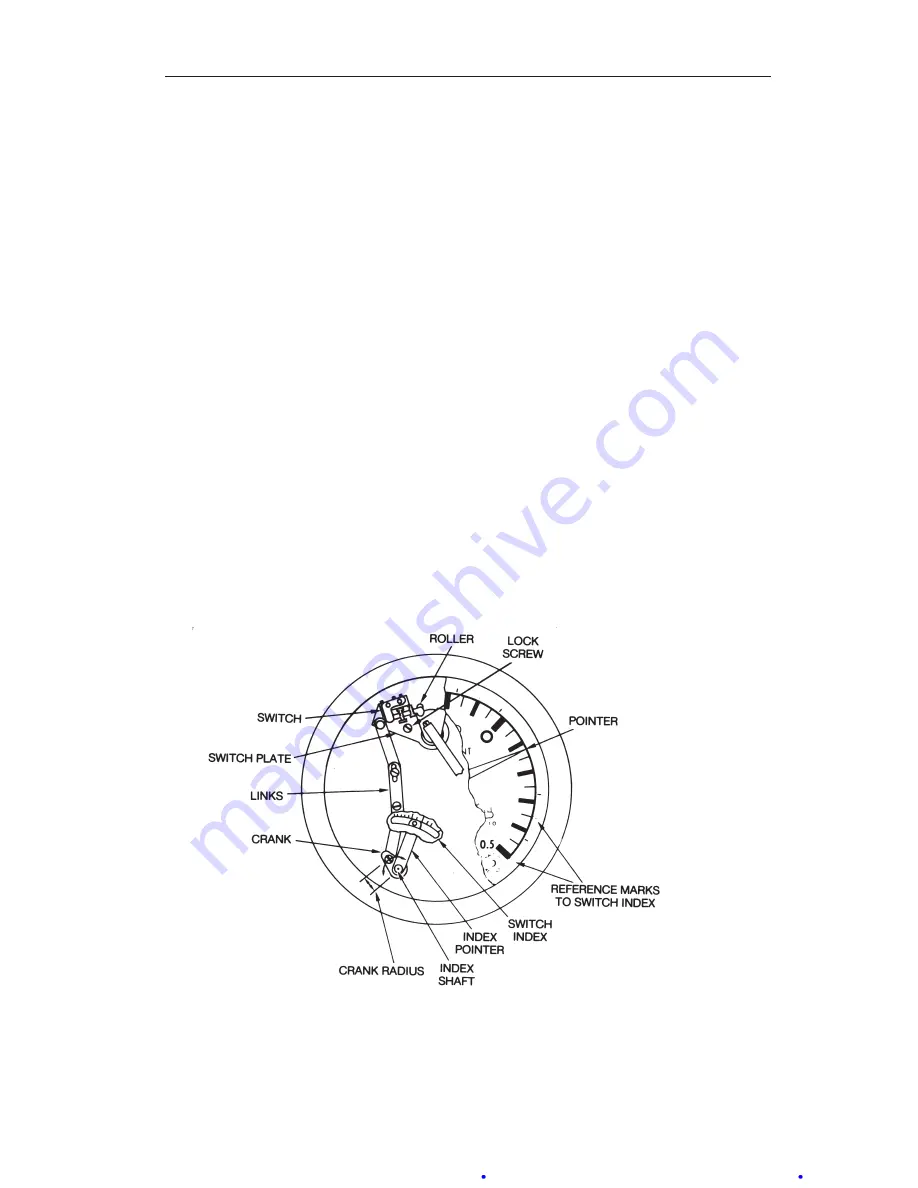

To calibrate the switch linkage (required when the unit is rebuilt), perform the

following steps. Refer to Figure 3.7 as needed.

1. Loosen the three linkage screws and turn the crank to the 12 o’clock

position.

2. Use a 1/8-inch Allen wrench to hold the index shaft and slip the index

pointer to 0 on the switch index. Tighten the screw on the crank to the

mid-slot position.

3. Turn the switch index pointer to “1” (index numbers refer to numbers on

outer edge of scale plate).

4. Apply 10% differential pressure and adjust the switch plate until the

switch actuates. Lock the two linkage screws.

5. Rotate the index pointer to “9.” Apply 90% differential pressure and

adjust the crank radius until the switch actuates.

6. Recheck 10% and 90% set points. Adjust the crank radius and the index

pointer until both set points are 2% accurate (nominal).

Figure 3.7—Linkage arrangement