E N G I N E E R E D & P R O C E S S V A L V E S

07/2011 / IOM-GEN-TWIN-03

29

Installation, Operation and Maintenance Manual

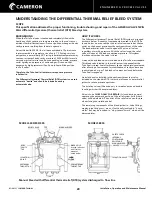

UNDERSTANDING THE DIFFERENTIAL THERMAL RELIEF BLEED SYSTEM

SCOPE

This specification addresses the proper functioning, trouble shooting, and repair of the GENERAL VALVE TWIN

SEAL differential (pressure) thermal relief (DTR) bleed system.

BACKGROUND

When the Twin Seal valve is seated and completely filled with a

liquid, any slight variation in temperature due to the sun’s rays or

ambient thermal fluctuations will cause significant changes in body

cavity pressure resulting from thermal expansion.

Valves filled with 330 API fuel oil have exhibited a 75 psi increase

in pressure with a temperature rise of only 1°F. Putting this into

perspective, a normal daily 30°F swing in ambient temperature may

cause an increase of body cavity pressure of 2250 psi. While results

vary under actual service conditions depending on media, pressure

vessel rigidity, and presence of entraned gas it is known that

dangerously high pressures will build up in liquid filled positive

shut-off valves.

Therefore, the Twin Seal in liquid service requires a pressure

relief device.

The Differential (pressure) Thermal Relief (DTR) system is one such

automatic “device” and should be included on every

automated valve.

HOW IT WORKS

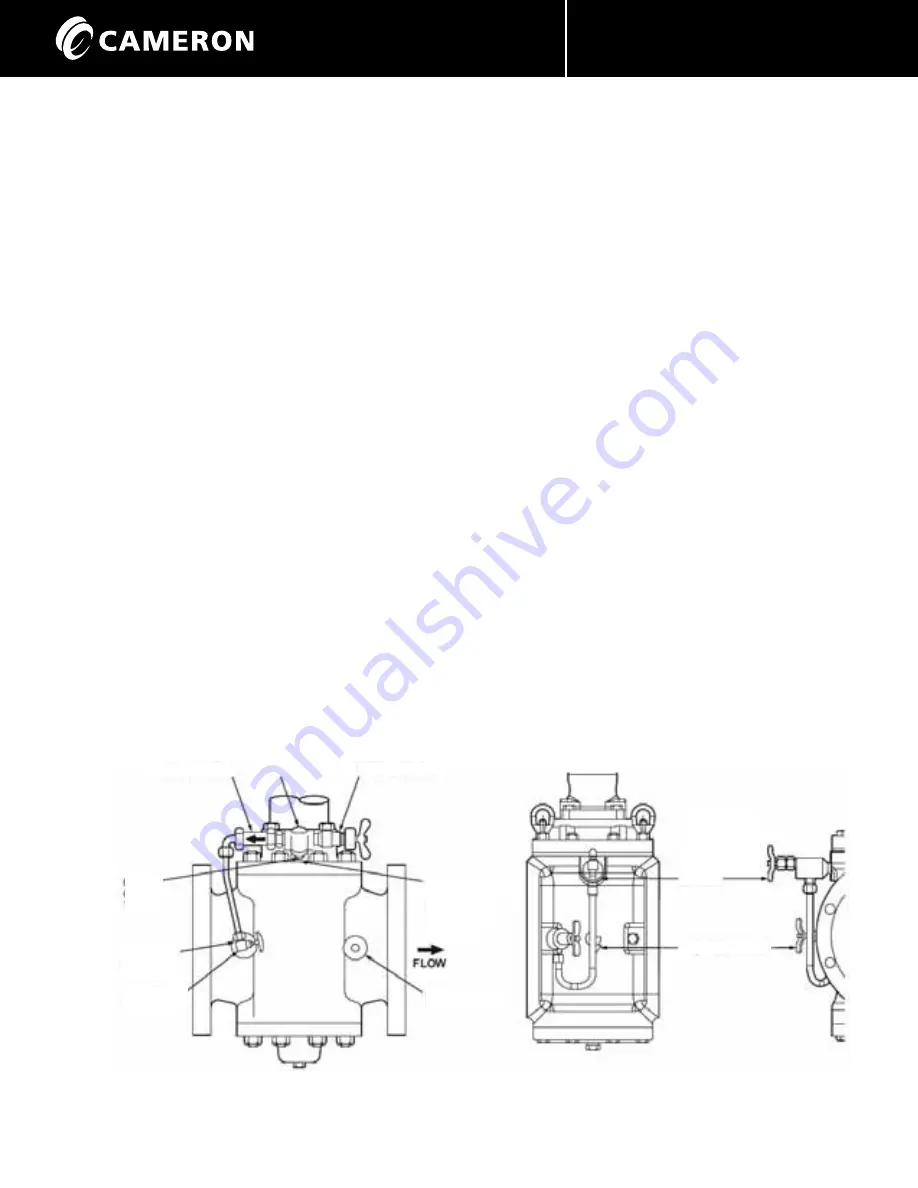

The Differential (pressure) Thermal Relief (DTR) system is arranged

as shown below. A variety of components are used in the DTR. As

shown below, one can see that the relief valve mounted at the tee

outlet on the bonnet pressurizes the upstream throat of the valve.

The standard relief valve is set to open at 25 psi on all valves

regardless of working pressure. With the valve closed, the relief

valve will open at 25 psi above upstream pressure. This system

functions only when the valve is closed.

A manual body bleed valve is included on the Twin Seal as standard.

This bleed valve installed in the relief system is openedafter the

Twin Seal is closed. Seal effectiveness can be immediately evaluated,

after allowing a few seconds for stabilization of cavity volume due

to entrained air or gas. The bleed valve must be closed before the

Twin Seal is reopened.

An isolation valve installed in the upstream throat tap is also

included on the standard DTR. It must be left open to permit relief

system to relieve pressure upstream.

The isolation valve will be used only for maintenance and trouble

shooting which will be explained later.

Valve is to be

CLOSED ONLY FOR REPAIR

. If closed during normal

operation the automatic portion of the relief system (relief/check

valve) will be defeated. (The outlet of the relief valve would close

when closing the isolation valve).

The remaining components of the bleed system i.e., tube fittings,

nipples, pipe fittings etc., are not functionally involved in “how it

works” but may be involved in “why it doesn’t work” which will be

discussed later.

MODELS 400/800/900

MODELS 8800

Manual bleed with differential thermal relief (DTR) system discharged to flow line

MANUAL BLEED

TEE

RELIEF VALVE

BODY

CAVITY

TAP

ISOLATION

VALVE

UPSTREAM

THROAT TAP

BLEED HOLE

located in bonnet

on all valves

except as

noted below

DOWNSTREAM

THROAT TAP

SAFETY CHECK

INTEGRAL

CONTAINING

RELIEF AND

MANUAL BLEED

VALVES

ISOLATION VALVE