E N G I N E E R E D & P R O C E S S V A L V E S

07/2011 / IOM-GEN-TWIN-03

31

Installation, Operation and Maintenance Manual

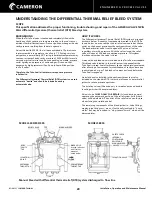

The Twin Seal valve requires no day-to-day maintenance,

however, there are some services which may be needed oc-

casionally.

ANNUALLY

1.

Drain plugs in the lower plate should be

removed and the residue flushed and drained from

the lower plate. In cold climates, before freezing

weather sets in, any possible collection of water

below valve plug or plug trunnion should be

drained out through the lower plate drain plugs.

SEMI-ANNUALLY

a.

Keep the valve operator housing full of lubricant to

displace and prevent moisture from accumulating

and freezing. The operator is provided with a

grease fitting. Lubricant should be injected with

the Twin Seal valve in the

open

position

only. Under ordinary conditions, a few

pumps of the grease gun semi-annually is sufficient.

Use lithium 12 hydroxy stearate or lithium base

molydisulfide grease.

SEMI-ANNUALLY

b.

If applicable, temporarily remove ABBV cover and

guide pin. Liberally apply grease in this area

semi-annually.

IF AT ANY TIME...

2.

If at any time the body bleed should indicate a leak

which cannot be stopped with ordinary force on

handwheel (no cheaters necessary), this may be

corrected by one of the following:

a)

Operate valve through open-close cycle while fluid

is flowing to flush out valve body. After several

flushing attempts, close the Twin Seal valve and check

body bleed again. If body bleed still indicates valve

leakage, proceed to b).

b)

If the valve is supplied with a DTR system, it is

possible that the relief valve may be leaking. Check

this by temporarily closing the line isolation valve.

If the leak stops, repair or replace the relief valve. If

this is not the case, the slips need inspection.

c)

To inspect or replace slips the line must be drained.

Then place the Twin Seal valve in the open position

(check body bleed valve for zero line pressure) and

remove lower plate (lower plate can be driven off by

closing valve, inserting a wedge and then opening

valve again). Slips can be removed from plug and

inspected or replaced if damaged. Be sure to save the

old slips and return to Cameron for exchange credit.

It is recommended to replace the lower plate O-Ring

and gasket any time the lower plate is removed and

slips are replaced.

If the lower plate is not accessible for replacing seating slips,

the valve operator and bonnet can be removed (Check

body bleed for zero line pressure before removing bonnet)

and slips replaced from the top of the valve.

3.

If stem packing needs replacement, it can be

changed as follows:

a) Remove operator as described in #4 below.

b) Remove packing gland and replace inner and outer

O-Rings and backup ring.

c) Remove packing rings and replace carefully.

d) Replace packing gland.

e) Replace operator as described in #4.

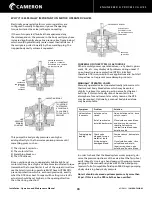

4.

To change operator:

a) Shut down line pressure.

b) Close GENERAL VALVE TWIN SEAL valve

extra tightly.

c) Open bleed valve for zero pressure when

removing operator.

d) Drive out coupling pin (towards guide pin boss).

e) Remove housing mounting bolts and lift

operator off.

f) Replace new operator in reverse order (insert

coupling pin from same side as guide pin boss.)

g) Close bleed valve.

h) Check operation of valve.

PARTS

Cameron’s Valves & Measurement group provide only new

factory replacement parts which are supplied through the

local Cameron Sales Office, details of which can be found

at www.c-a-m.com.

O-Rings, gland packing and gaskets are packaged into kits

that make ordering simple. Be sure to specify valve size,

series, part number from the slip and type of resilient seal

material when ordering replacement slips. Ask about

Cameron’s Slip Exchange Program

Cameron, through CAMSERV Aftermarket Services also

offers remanufactured valves, emergency repairs, technical

assistance, maintenance contracts, commissioning and

service training seminars.

OPERATION & MAINTENANCE