Machine Stopping

1.

When stopping the machine after normal operation, lower engine speed to “SLOW”, and release

operator presence control.

A rotating cutting wheel is very DANGEROUS! Stand at controls and ensure that cutting

wheel comes to a complete stop before doing anything else.

2.

Set park brake before leaving controls.

3.

Turn engine switch to “OFF”.

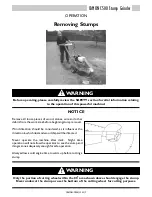

Helpful Tips for Operating Machine

1.

Use smooth, comfortable speeds while operating.

2.

When it is desired to cut smaller roots, it may be more effective to do so before, rather than after, cutting

the stump.

3.

Should the chip build-up become excessive when cutting, shut off the machine, wait for the cutting wheel

to stop rotating, retract the machine from the stump, and rake away chips. It is also possible to use the

cutter wheel to push chips off to the side.

4.

On larger stumps, when cutting from one side, eventually a tyre may tend to roll into the hole. This may

be prevented by moving the machine to another side of the stump to continue removal, or by filling the

hole with chips before continuing.

WARNING

!

CAMON-C500/11.11/10

CAMON-C500/11.11/11

CAMON C500 Stump Grinder

CAMON C500 Stump Grinder

OPERATION

OPERATION

While in Operation

1.

Know how to shut the machine off in an emergency.

2.

The operator must never leave the controls while the machine is in operation.

3.

Never let clothing, long hair, jewelry, etc hang loosely. It is possible that they can become dangerously

entangled in the moving parts or in the controls of the machine.

4.

Keep head, hands, and feet away from moving parts at all times.

5.

The engine should not be started within a building unless it is properly ventilated so as to eliminate the

breathing of exhaust fumes, which can cause death.

6.

Check for proper operation of all controls and protective devices while operating them slowly.

7.

Extreme caution must be exercised when cutting stumps on slopes, as the machine may shift or slide

unpredictably. Never attempt to cut with the machine uphill or downhill from your person. The machine

may slide toward you, or you may fall toward the machine. Cut only on a slope from the side. Never

O.

attempt to cut on a slope exceeding 15

8.

Never operate the machine after dark.

9.

Wear appropriate safety equipment, including protective eyeglasses, face shield, protective footwear, and

hearing protection.

10. For safety, local or job site operating directives may require a greater distance from obstacles.

11. Keep eye contact with cutting wheel at all times that it is rotating.

12. Use only the front lower portion of the cutting wheel below the shaft. Never undercut the stump, or use

the upper portion of the wheel for cutting purposes.

13. Occasionally, a curtain may become displaced in such a way as to leave a normally covered area exposed.

Shut down the machine immediately if it occurs, and reposition the curtain before continuing operation.

14. Ensure that everyone in the vicinity is aware of the DANGER ZONE associated with this machine. (See

BEFORE STARTING THE ENGINE section). You and they must avoid the DANGER ZONE at all times

when the machine is in operation.