255-100 Novalynx

Analogue Output Evaporation Gauge

5

6. Installation

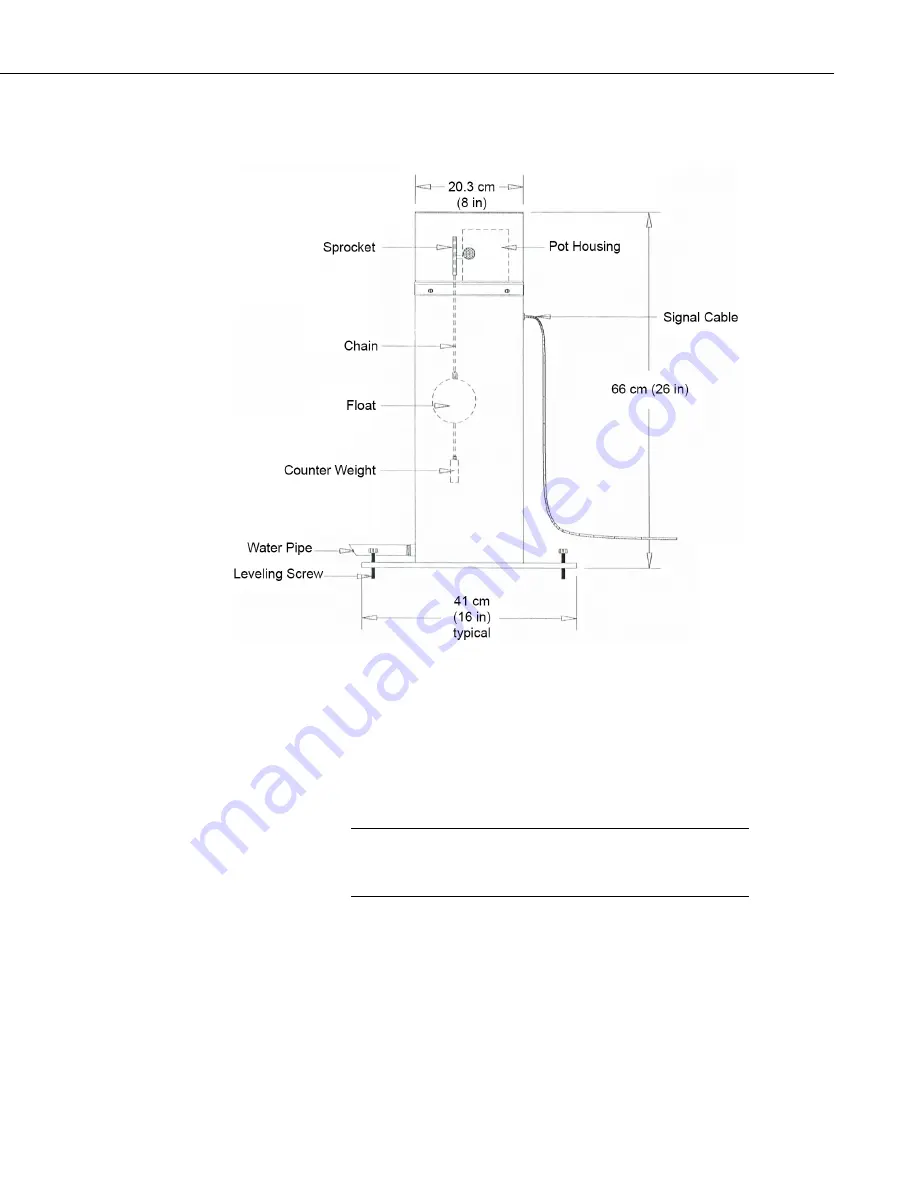

FIGURE 6-1. Components of the 255-100 Evaporation Ga

u

ge

6.1 Unpacking

Carefully unpack all of the evaporation ga

u

ge. Remove the top cover. The

float with chain and counter-weight are shipped inside the bottom of the

ga

u

ge housing. Remove packing material from inside the housing. The float

cannot be removed without removing the pot/gear assembly housing.

Carefully remove the packing materials and parts from

inside the ga

u

ge, and avoid hitting the potentiometer

sprocket wheel.

6.2 Siting

The site should be level and free of nearby obstructions that can cast shadows

or reflect sunlight onto the evaporation pan. To avoid shadows or reflection,

the evaporation ga

u

ge should be north of the evaporation pan. Placing the

ga

u

ge away from the pan also helps reduce shadows and reflections.

The evaporation pan should sit upon a level wooden platform that is placed

over soil typical of the area. Dimensions of the platform need to be 127 x 127 x

CAUTION