Section 8. Operation

393

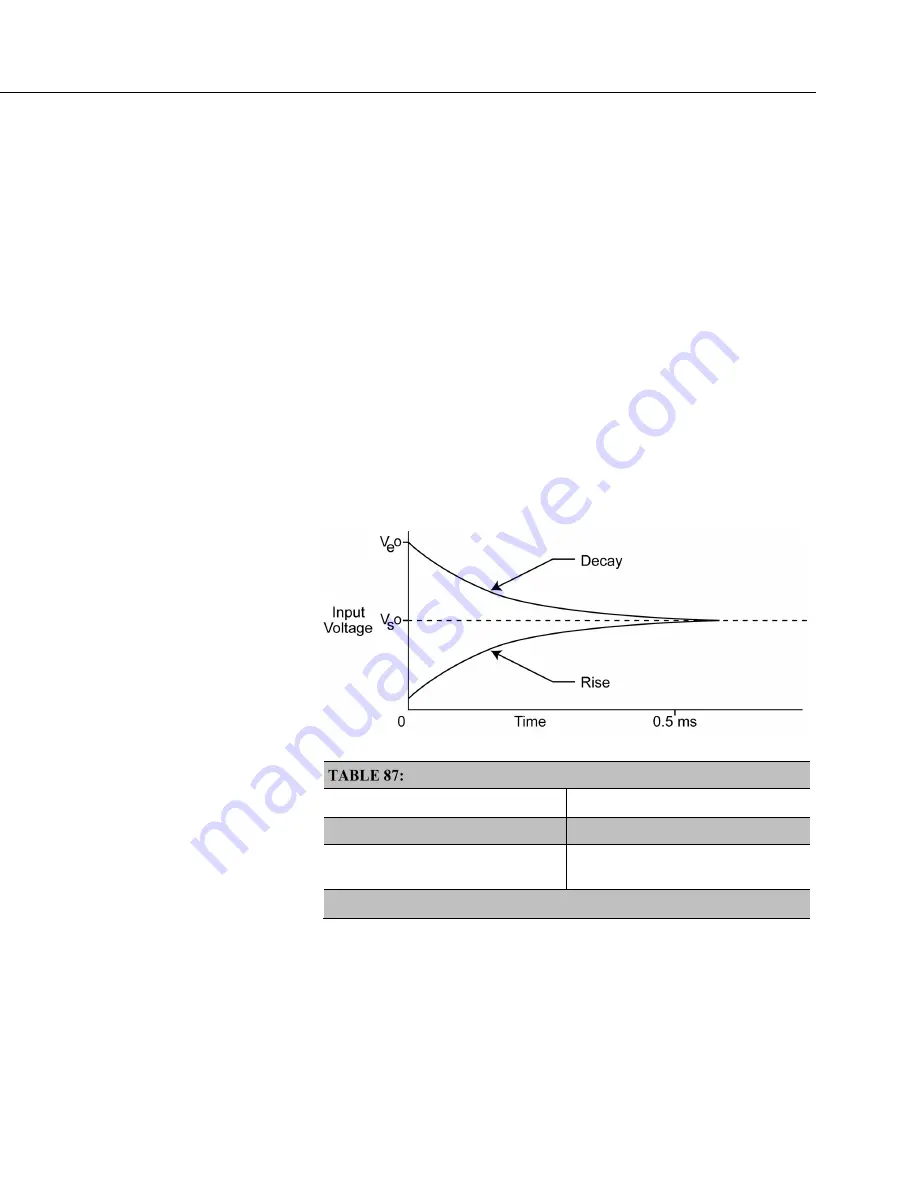

The rate at which the signal settles is determined by the input settling time

constant, which is a function of both the source resistance and fixed-input

capacitance (4.7 nfd) of the CR6.

Rise and decay waveforms are exponential. Figure

Input Voltage Rise and

Transient Decay

(p. 393)

shows rising and decaying waveforms settling closer to the

true signal magnitude, V

so

. The

SettlingTime

parameter of an analog

measurement instruction allows tailoring of measurement instruction settling

times with 100 µs resolution up to 600000 µs.

Settling times are listed in table

CRBasic Measurement Settling Times

(p. 393).

Default settling times (those resulting when

SettlingTime

=

0

) provide sufficient

settling in most cases. Additional settling time is often programmed when

measuring high-resistance (high-impedance) sensors or when sensors connect to

the input terminals by long leads.

Measurement time of a given instruction increases with increasing settling time.

For example, a 1 ms increase in settling time for a bridge instruction with input

reversal and excitation reversal results in a 4 ms increase in time for the CR6 to

perform the instruction.

FIGURE 84: Input voltage rise and transient decay

b

CRBasic Measurement Settling Times

SettlingTime

Argument

Resultant Settling Time

1

0

500 µs

integer between

100

and

600000

,

inclusive

μs entered in

SettlingTime

argument

1

500 µs is the default voltage measurement settling time.

Settling Errors

When sensors require long lead lengths, use the following general practices to

minimize settling errors:

•

Do not use wire with PVC-insulated conductors. PVC has a high

dielectric constant, which extends input settling time.

Summary of Contents for CR6 Series

Page 2: ......

Page 4: ......

Page 6: ......

Page 32: ......

Page 36: ......

Page 38: ......

Page 76: ...Section 5 Overview 76 FIGURE 20 Half Bridge Wiring Example Wind Vane Potentiometer ...

Page 80: ...Section 5 Overview 80 FIGURE 23 Pulse Input Wiring Example Anemometer ...

Page 136: ......

Page 454: ...Section 8 Operation 454 FIGURE 104 Narrow Sweep High Noise ...

Page 459: ...Section 8 Operation 459 FIGURE 106 Vibrating Wire Sensor Calibration Report ...

Page 535: ...Section 8 Operation 535 8 11 2 Data Display FIGURE 121 CR1000KD Displaying Data ...

Page 537: ...Section 8 Operation 537 FIGURE 123 CR1000KD Real Time Custom ...

Page 538: ...Section 8 Operation 538 8 11 2 3 Final Storage Data FIGURE 124 CR1000KD Final Storage Data ...

Page 539: ...Section 8 Operation 539 8 11 3 Run Stop Program FIGURE 125 CR1000KD Run Stop Program ...

Page 541: ...Section 8 Operation 541 FIGURE 127 CR1000KD File Edit ...

Page 546: ......

Page 552: ......

Page 610: ...Section 11 Glossary 610 FIGURE 137 Relationships of Accuracy Precision and Resolution ...

Page 612: ......

Page 648: ......

Page 650: ......

Page 688: ......

Page 689: ......