Section 7. Installation

289

'SIMULATE SIGNAL THEN MAKE THE MEASUREMENT

'Zero calibration is applied when variable CalMode = 6

ExciteV

(U11,SimulatedSalinitySignal,0)

VoltSE

(Salinity,1,mV5000,U1,1,0,15000,0.05,SalinityOffset)

'PERFORM AN OFFSET CALIBRATION.

'Start by setting variable CalMode = 1. Finished when variable CalMode = 6.

'FieldCal(Function, MeasureVar, Reps, MultVar, OffsetVar, Mode, KnownVar, Index, Avg)

FieldCal

(1,Salinity,1,0,SalinityOffset,CalMode,KnownSalinity,1,30)

'If there was a calibration, store calibration values into data table CalHist

CallTable

(CalHist)

NextScan

EndProg

7.7.12.5.3 FieldCal() Slope and Offset (Opt 2) Example

Most CRBasic measurement instructions have a

multiplier

and

offset

parameter.

FieldCal()

Option 2

adjusts the

multiplier

and

offset

arguments such that the

output of the sensor being calibrated is set to a value consistent with the linear

relationship that intersects two known points sequentially entered in the

FieldCal()

KnownVar

parameter. Subsequent measurements are scaled with the

same multiplier and offset.

Example Case: A meter measures the volume of water flowing through a pipe.

Multiplier and offset are known to drift, so a two-point calibration is required

periodically at known flow rates. The following procedure adjusts multiplier and

offset to correct for meter drift as shown in the calibration report below. Note that

the flow meter outputs millivolts inversely proportional to flow.

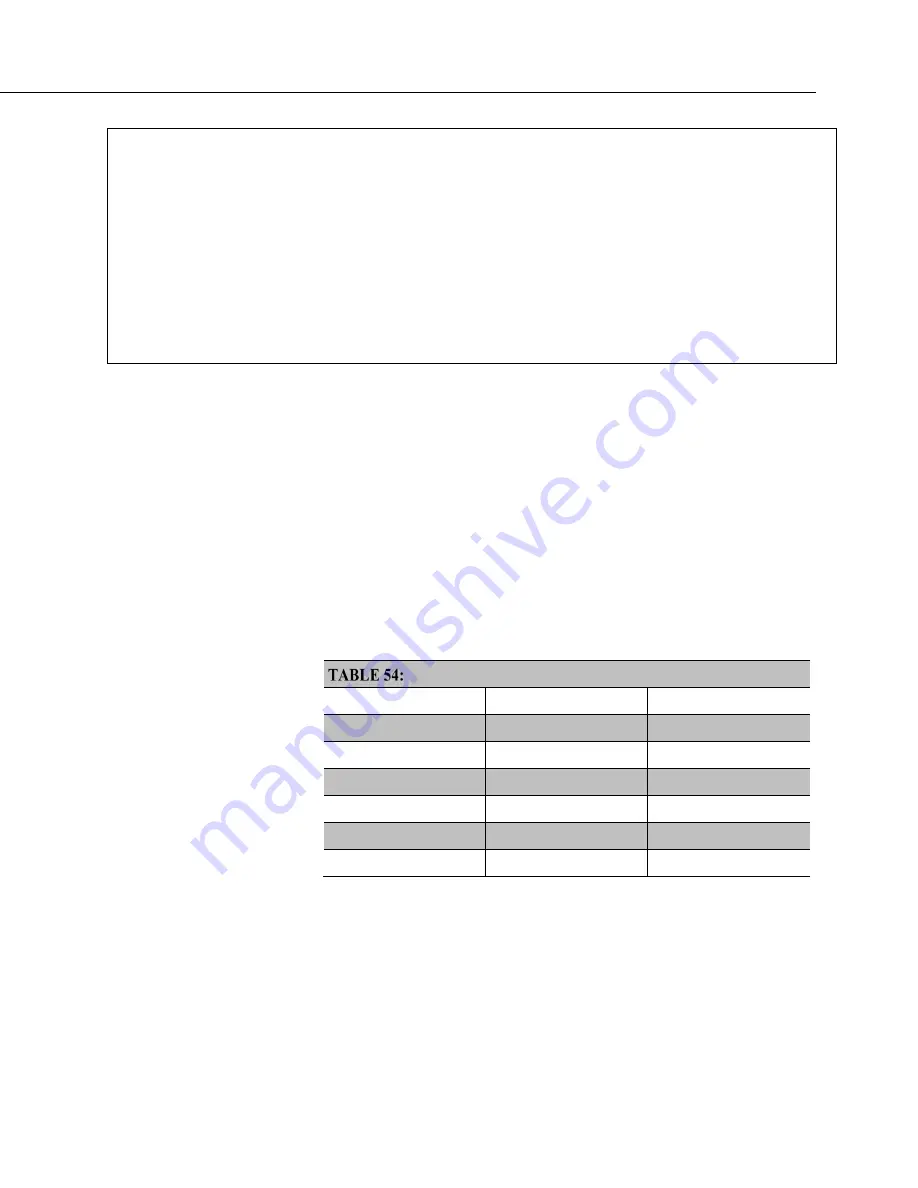

Calibration Report for Flow Meter

CRBasic Variable

At Deployment

At Seven-Day Service

SimulatedFlowSignal

300

mV

285

mV

KnownFlow

30

L/s

30

L/s

SimulatedFlowSignal

550

mV

522

mV

KnownFlow

10

L/s

10

L/s

FlowMultiplier

-0.0799

L/s/mV

-0.0841

L/s/mV

FlowOffset

53.90

L

53.92

L

1. Send CRBasic example

FieldCal() Two-Point Slope and Offset

(p. 290)

to the

CR6.

2. To place the simulated flow sensor in a simulated calibration condition (in the

field a real sensor would be placed in a condition of know flow), place a

jumper wire between terminals

U1

and

U11

.

Summary of Contents for CR6 Series

Page 2: ......

Page 4: ......

Page 6: ......

Page 32: ......

Page 36: ......

Page 38: ......

Page 76: ...Section 5 Overview 76 FIGURE 20 Half Bridge Wiring Example Wind Vane Potentiometer ...

Page 80: ...Section 5 Overview 80 FIGURE 23 Pulse Input Wiring Example Anemometer ...

Page 136: ......

Page 454: ...Section 8 Operation 454 FIGURE 104 Narrow Sweep High Noise ...

Page 459: ...Section 8 Operation 459 FIGURE 106 Vibrating Wire Sensor Calibration Report ...

Page 535: ...Section 8 Operation 535 8 11 2 Data Display FIGURE 121 CR1000KD Displaying Data ...

Page 537: ...Section 8 Operation 537 FIGURE 123 CR1000KD Real Time Custom ...

Page 538: ...Section 8 Operation 538 8 11 2 3 Final Storage Data FIGURE 124 CR1000KD Final Storage Data ...

Page 539: ...Section 8 Operation 539 8 11 3 Run Stop Program FIGURE 125 CR1000KD Run Stop Program ...

Page 541: ...Section 8 Operation 541 FIGURE 127 CR1000KD File Edit ...

Page 546: ......

Page 552: ......

Page 610: ...Section 11 Glossary 610 FIGURE 137 Relationships of Accuracy Precision and Resolution ...

Page 612: ......

Page 648: ......

Page 650: ......

Page 688: ......

Page 689: ......