CS230/CS231 Temperature Profiler

7

7.2 Mounting

Orient and secure the CS230/CS231 in the measurement medium. Keep

materials removed during installation and use that material as backfill.

While installing the CS230/CS231, the depth must be referenced between the

surface of the medium and the first measurement point in the assembly (shown

, Internal Sensor Position #4). If the rigid assembly is not

placed at the correct depth, all measurement depths will be out of place.

Install the external probes horizontally in the measurement medium. This helps

ensure that the most representative measurement is taken at the given depth,

and will not interfere with other nearby measurements.

Orient the signal and power cable of the CS230/CS231 towards the data logger

to avoid loops or strain on the cable. Also use a suitable trench or conduit to

protect the signal and power cable from damage.

7.3 Wiring

provides the connections for the CS230/CS231 and Campbell

Scientific data loggers. Refer to Appendix

SGB3 Electrical Surge Protector

(p. D-1)

, if the CS230 serial number is less than 1162.

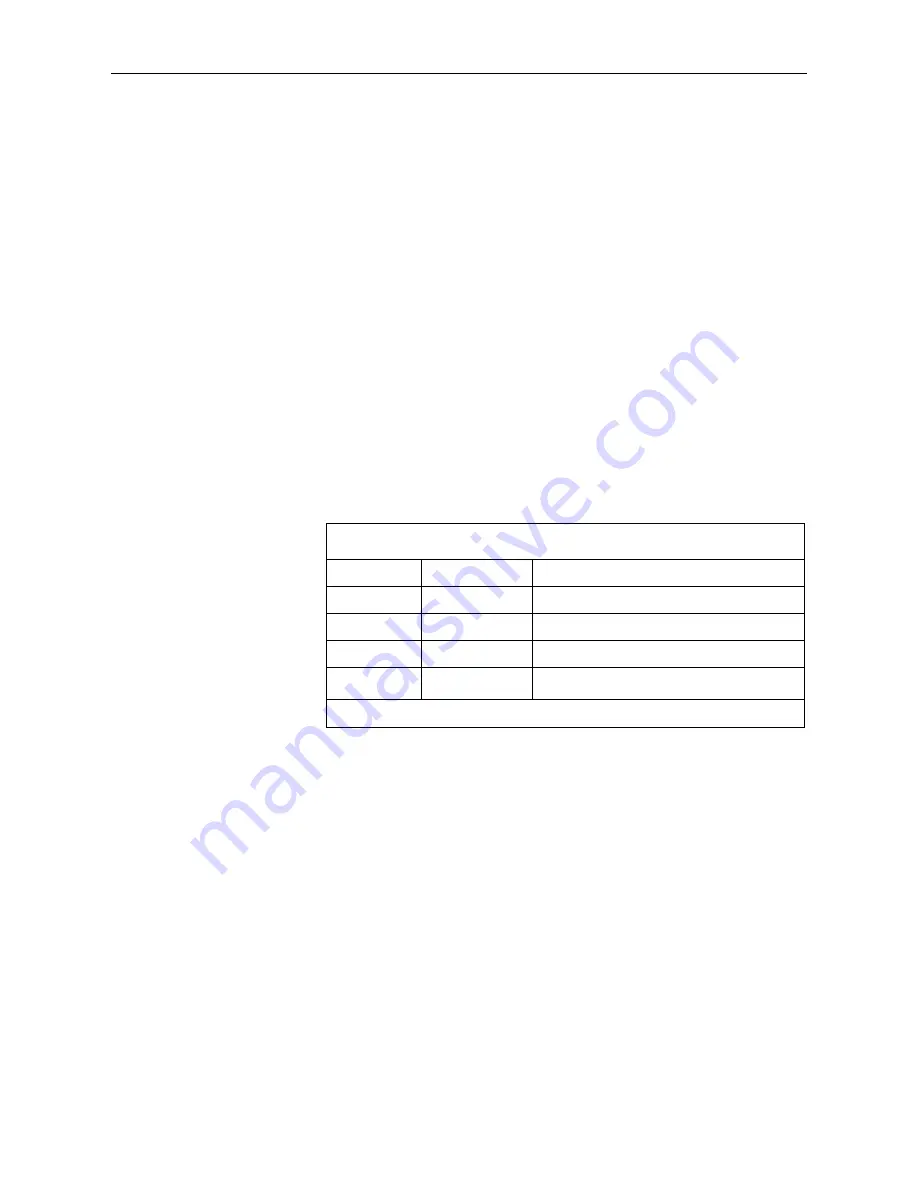

TABLE 7-1. Wire Colo

u

r, Function, and Data Logger Connections

Wire Colo

u

r

Function

Data Logger Connection Terminal

Red

Power

12V

Green

SDI-12 Signal

C

or

U

1

terminal configured for SDI-12

Black

Power Ground

G

Clear

Shield

⏚

1

U

terminals are automatically configured by the measurement instruction.

If multiple SDI-12 sensors are connected to a data logger, Campbell Scientific

recommends using separate terminals when possible. For the CR6 and

CR1000X, triggering conflicts may occur when a companion terminal is used

for a triggering instruction such as

TimerInput()

,

PulseCount()

, or

WaitDigTrig()

. For example, if the CS230/CS231 is connected to C3 on a

CR1000X, C4 cannot be used in the

TimerInput()

,

PulseCount()

, or

WaitDigTrig()

instructions.

7.4 Programming

Short Cut

is the best source for up-to-date data logger programming code. If

your data acquisition requirements are simple, you can probably create and

maintain a data logger program exclusively with

Short Cut

. If your data

acquisition needs are more complex, the files that

Short Cut

creates are a great

source for programming code to start a new program or add to an existing

custom program.

Short Cut

cannot edit programs after they are imported and edited in

CRBasic

Editor

.