SECTION 3. ET INSTRUMENTATION INSTALLATION

3-3

b) After determining the tilt angle,

loosen the two bolts that attach the

mounting bracket to the panel.

Adjust the angle, then tighten the

bolts. Secure the lead wire to the

mast using wire ties. Make

electrical connections as described

in 2b above.

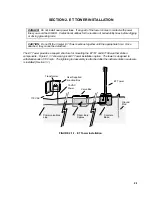

3.1.3 AC POWER INSTALLATION

a) The AC power option includes a

120 VAC to 16 VAC. The

transformer should be mounted

inside a user supplied junction box

according to local electrical codes.

Dangerous electrical accidents may

be avoided by locating the

transformer remotely and burying a

low voltage line to the station. The

low voltage will carry up to 500 feet

on an 18 AWG power cable.

b) Shut off 110 VAC power at the

main breaker. Connect the primary

leads of the transformer to 110

VAC following instructions provided

with the transformer. Connect a

two conductor cable to the

secondary terminals of the

transformer. Route the cable from

the transformer to the ET Enclosure

according to local electrical codes.

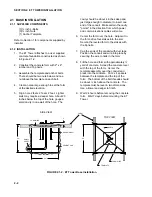

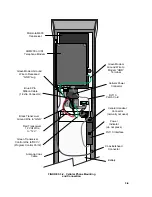

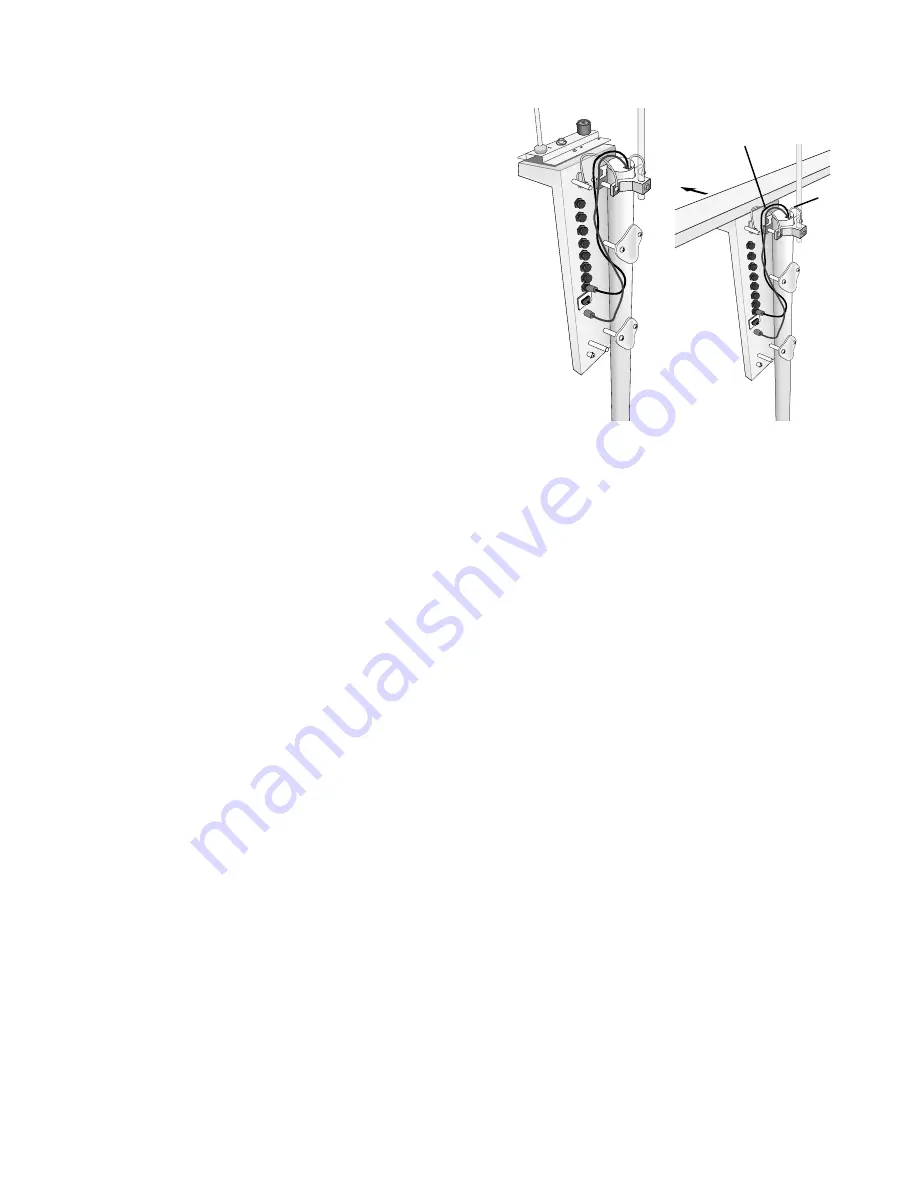

3.1.4 ENCLOSURE INSTALLATION

1.

Mount and ground the ET enclosure on the

ET Tower as shown in Figure 3.1-4.

a) Place the enclosure low on the

tower. Do not tighten clamps.

b) Install the sensor arm (ET106) or

reduced sensor set as described in

Section 4.

NORTH

FIGURE 3.1-4. Mounting and Grounding

the ET Enclosure

c)

Slide the enclosure to the top of the

ET tower. Position it on the north

side of the tower (northern

hemisphere). The top of the

enclosure should be flush with the

top of the tower, with the width of

the sensor arm extending above

the tower. Tighten the clamps until

the enclosure is snug. Do not over-

tighten since doing so may damage

the tower or enclosure.

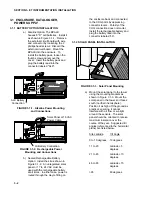

d) Carefully mount the lightning rod

and clamp to the top of the ET

Tower. Clearance between the

clamp and the enclosure is

minimal. Care should be taken not

to scratch the enclosure or sensor

assembly. Strip 1 inch of insulation

from the top end of the 12 AWG

green tower ground wire, curl the

end and place the curled end under

the head of one of the lightning rod

clamp bolts. Tighten the bolt.

e) Strip 1 inch of insulation from each

end of the 9 inch piece of 12 AWG

ground wire. Insert one end into

the brass ground lug located at the

top back of the enclosure. Curl the

other end and place under the head

of one of the lightning rod clamp

bolts. Tighten the bolt.

9-inch

Ground

Wire

Tower

Ground

Wire

Summary of Contents for ET101

Page 4: ...This is a blank page ...

Page 12: ......

Page 26: ......

Page 30: ......

Page 32: ......

Page 36: ......

Page 37: ...This is a blank page ...