3. Make sure the communication device at the computer is properly configured and cabled

(

(p. 35)).

4. Call your local Toro distributor if still no response.

7.2.3 NAN, ±INF, or unreasonable results displayed in a

variable or stored in a data table

1. Make sure the battery voltage is between 9.6 and 16 VDC.

2. Verify sensors are plugged into the correct sensor connector and the locking ring is

securely in place (see

3. Check connectors for any corrosion on pins.

4. If Short Cut or VisualWeather is used to create the station program, double check the

wiring diagram to see if it matches the physical wiring on the sensor connectors on the

back of the enclosure.

5. If CRBasic is used to create the station program, verify channel assignments and multipliers.

Data logger program may need to be changed.

6. Inspect the sensor for damage and/or contamination. If damaged, contact your local Toro

distributor for repair or purchase of a replacement sensor.

7.2.4 WindSonic1-ET diagnostic codes

The WindSonic outputs a diagnostic code (

(p. 67)) with each wind direction and speed

measurement. A data logger program can be written that filters out all data when the diagnostic

is not 0. The programs can also report the number of good samples that were used in computing

the on-line statistics. If the total number of good samples is less than 98% of the expected

samples, the WindSonic may be in need of repair.

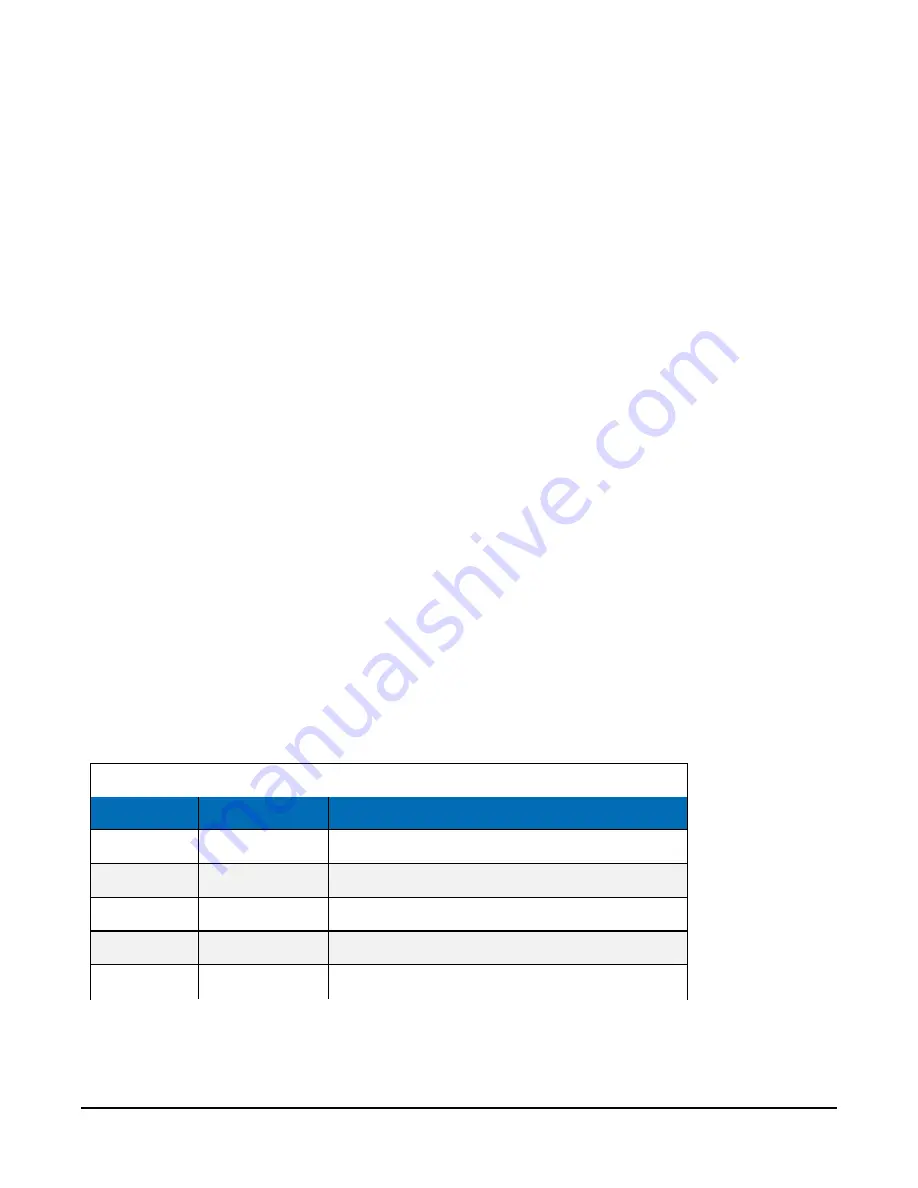

Table 7-2: WindSonic Diagnostic Codes

Diagnostic

Status

Comment

0

Okay

All okay

1

Axis 1 Failed

Insufficient samples, possible path obstruction

2

Axis 2 Failed

Insufficient samples, possible path obstruction

4

Both Axis Failed Insufficient samples, possible path obstruction

8

NVM error

Nonvolatile Memory checksum failed

Section 7. Maintenance and troubleshooting

67