6

ADJUSTMENTS

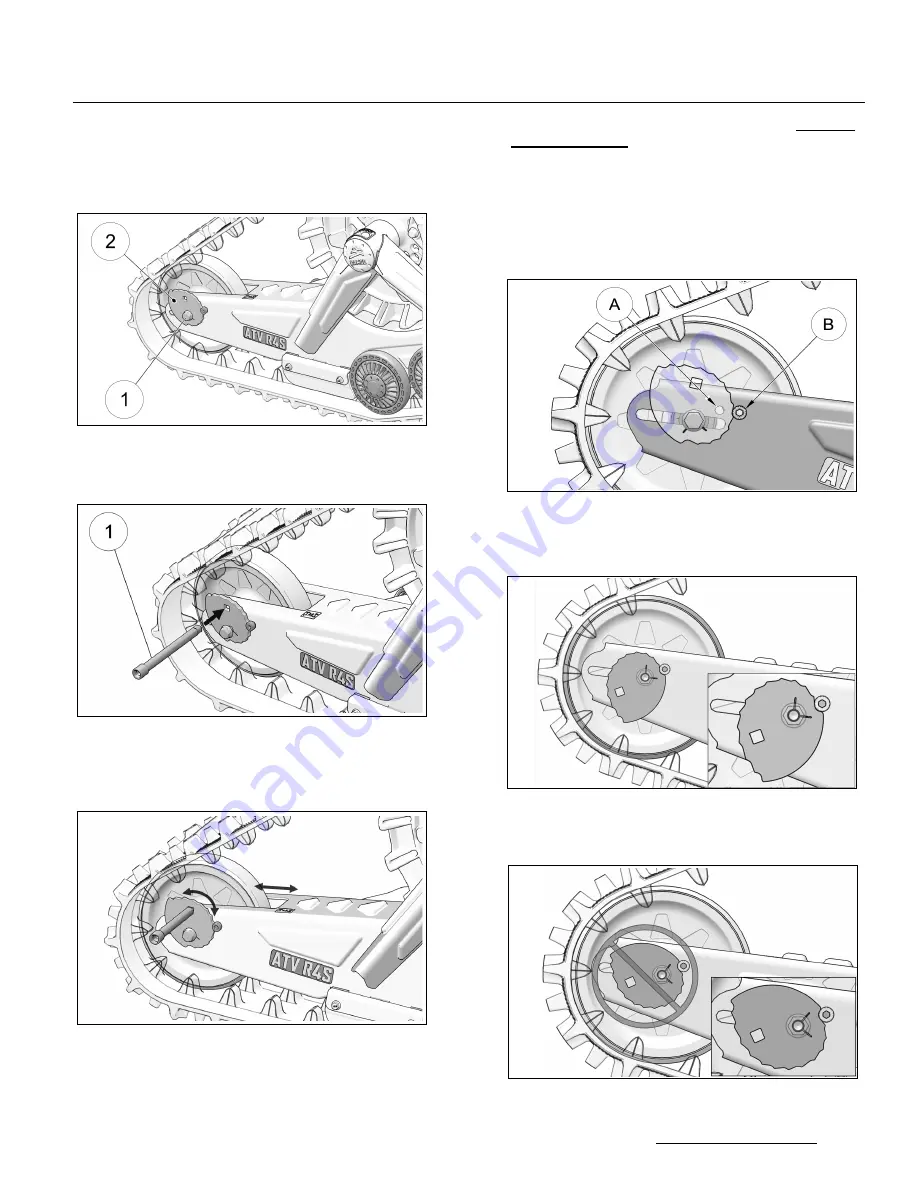

TRACK TENSION

• Loosen both tensioner side wheel shaft bolts

(

1

), enough to allow tensioner cams (

2

) to turn.

Figure 24

• Insert ratchet wrench extension with 3/8” drive

(

1

) in tensioner cam’s square hole. Figure 25.

Figure 25

• Turn cam on each side and adjust tension as

close as possible to the recommended

tension. Figure 26.

Figure 26

CAUTION: Tensioner cam adjustment position

must identical on both sides of Track System.

Verify adjustment by counting at which position

each cam is set. Both positions must be the same.

• After having adjusted the tension and

verified

cam positions

, re-tighten both wheel shaft

bolts to 50 N-m (37 lb-ft) of torque.

• Position of Tensioner cam locking bolts:

(

A

) - System with 15 or 16-tooth sprockets.

(

B

) - System with 17 or 18-tooth sprockets. See

Figure 27

• Installation direction of Tensioner cams. Figure

29 and Figure 29.

Figure 28

NOTE: With tensioner cam in position 0, the small

slots cut at 90

o

should indicate 3 o’clock.

Figure 29

Correct

Wrong