5

appliance remaining connected to the common venting system placed in operation, while the

other appliances remaining connected to the common venting system are not in operation.

a) Seal any unused openings in the common venting system.

b) Visually inspect the venting system for proper size and horizontal pitch and determine

that there is no blockage, restriction, leakage, corrosion or other deficiency, which could

cause an unsafe condition.

c) Insofar as is practical, close all building doors and windows and all doors between the

space in which the appliances remaining connected to the common venting system are

located and other spaces of the building.

Turn on the clothes dryers and any appliances not connected to the common venting system.

Turn on any exhaust fans, such as range hoods and bathroom exhausts, so they will operate at

maximum speed, do not operate a summer exhaust fan. Close fireplace dampers.

d) Place in operation the appliance being inspected. Follow the lighting instructions. Adjust

thermostat so that appliance operates continuously.

e) Test for spillage at the draft hood relief opening after 5 minutes of main burner operation.

Use the flame of a match or candle or smoke from a cigarette.

f) After it has been determined that each appliance remaining connected to the common

venting system properly vents when tested as outlined above, return doors, windows,

exhaust fans, fireplace dampers and any other gas-burning appliance to their previous

condition of use.

g) Any improper operation of the common venting system must be corrected so that the

installation conforms to the National Fuel Gas Code, ANSI Z223.1 or CAN/CGA B149,

Installation Codes. When resizing any portion of the common venting system, the

common venting system should be resized to approach the minimum size as determined

using the appropriate tables in Part 11 of the National Fuel Gas Code, ANSI Z223.1 or

CAN/CGA B149, Installation Codes.

Heat exchanger surfaces and vent piping should be checked every six months for deterioration

and carbon deposits. Remove all soot or other obstructions from the chimney and flue, which

might impede draft action. Replace any damaged or deteriorated parts of the venting system.

A qualified service technician should follow this procedure when inspecting and cleaning the

heat exchanger and vent pipe.

1. Turn off electrical power and close main manual gas shut-off and allow boiler to cool

down

2. Remove the boiler draft diverter and vent pipe running to chimney.

•

Check heat exchanger, vent and chimney for obstruction and clean as

necessary.

3. Remove burner tray from boiler and vacuum top heat exchanger and coils.

4. Reinstall parts removed in steps 2 and 3.

•

Be sure that vent pipe has proper pitch and is properly sealed.

5. Restore electrical power and gas supply to boiler.

•

Place boiler in operation using lighting instructions provided.

•

Check for gas leaks and proper vent operation.

Summary of Contents for BLUE-FLAME Series

Page 21: ...19...

Page 22: ...20...

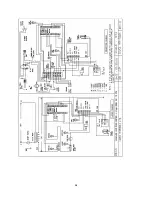

Page 23: ...21 21 EXPLODED VIEW...