12

PART 3

GAS CONNECTION

Verify that the appliance is supplied with the type of gas

specified on the rating plate. Consult factory for installations

at high altitude.

3.1

GAS CONNECTION

•

Safe operation of unit requires properly sized gas supply

piping. See gas line sizing data.

•

Gas pipe size may be larger than appliance connection.

•

Installation of a union at the appliance gas line

connection is required for ease of service and removal

of the gas train.

•

Install a manual main gas shutoff valve, outside of the

appliance gas connection as require by local codes.

•

A trap (drip leg) MUST be provided in the inlet gas

connection to the appliance.

•

Optional gas controls may require routing of bleeds and

vents to the atmosphere, outside the building when

required by local codes.

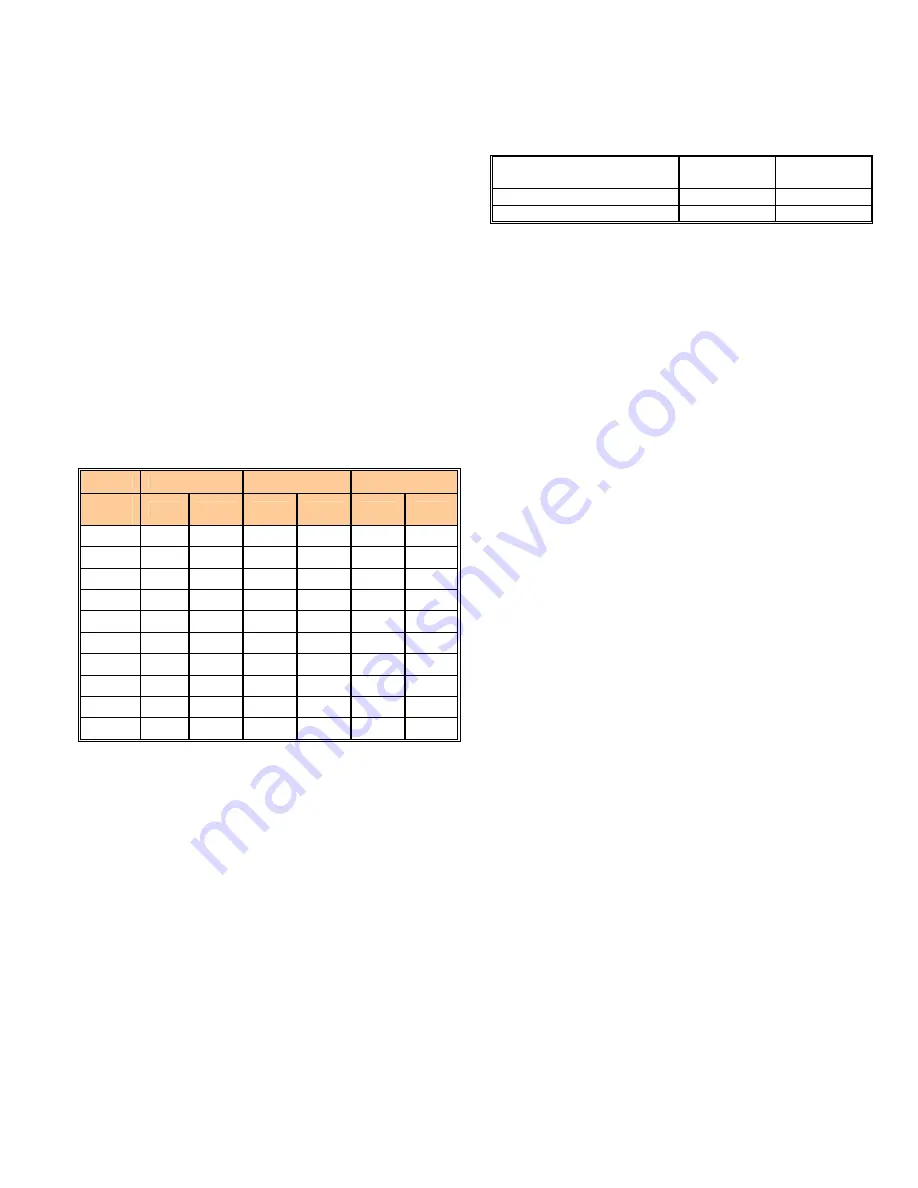

Table 9: Recommended Gas Pipe Size

Single Appliance Installation

(For distance from natural gas meter or propane second

stage regulator)

Input

0-100 FT

101-200 FT

201-300 FT

Btu/Hr,

x1000

NAT.

L.P.

NAT.

L.P.

NAT.

L.P.

80

¾”

½”

¾”

½”

1”

¾”

100

¾”

½”

1”

¾“

1”

¾”

150

1”

¾”

1 ¼”

1“

1 ¼”

1”

200

1”

¾”

1 ¼”

1”

1 ¼”

1”

250

1 ¼”

1”

1 ¼”

1”

1 ½”

1 ¼”

299

1 ¼“

1“

1 ½”

1 ¼“

1 ½“

1 ¼“

399

1 ¼“

1“

1 ½“

1 ¼“

2“

1 ½“

500

1 ½“

1 ¼“

2“

1 ½“

2“

1 ½“

600

1 ½“

1 ¼“

2“

1 ½“

2“

1 ½“

750

2“

1 ½“

2“

1 ½“

2 ½“

2“

3.2

GAS PIPING

All gas connections must be made with pipe joint compound

resistant to the action of liquefied petroleum and natural gas.

All piping must comply with local codes and ordinances.

3.3

INSTALL PIPING

•

The gas line should be sufficient to handle the total

installed capacity. Verify pipe size with your gas

supplier.

•

Use approved piping as per code free from burrs.

•

Install a manual main gas shutoff valve at the appliance

gas inlet, outside of the appliance and before the gas

valve.

•

Run pipe to the Appliance gas inlet.

•

Install a sediment trap in the supply line to the Appliance

gas inlet.

•

Apply a moderate amount of good quality pipe

compound.

•

For LP gas, consult your LP gas supplier for expert

installation.

The appliance and its individual gas shut-off valve must be

disconnected from the supply piping when pressure testing

the gas supply piping at pressures above ½ PSI

Table 10: Gas Pressures at Inlet to Appliance

PROPANE

NATURAL

GAS

Minimum (inches W.C.)

11

3

Maximum (inches W.C.)

11

14

The gas supply line must be of adequate size to prevent

undue pressure drop and must never be smaller than the

size of the connection on the appliance. Sizing based on

Table 4 or 6 is recommended, depending on model.

Before operating the appliance, the complete gas train and

all connections must be tested using soap solution.

Verify that the appliance is supplied with the type of gas

specified on the rating plate. Heating values of local natural

gas are to be between 950 and 1010 Btu/ft

3

. Consult factory

if heating values are outside this range or if a gas with a

mixture of constituents is being used.

3.4

CHECKING GAS SUPPLY PRESSURE

•

Turn the main power switch to “OFF” position.

•

Shut off gas supply at the manual gas cock in the gas

piping to the appliance. If fuel supply is LP gas, shut off

gas supply at the tank.

•

Remove the 1/8" hex plug from the gas pressure test

port located on the inlet gas supply connection at the

rear of the appliance. Install a fitting in the inlet pressure

tapping suitable to connect to a manometer or

magnahelic gauge. Range of scale should be 0 to 14

inch W.C. or greater to check inlet pressure

•

Turn on gas supply at the field installed manual gas

cock; turn on LP gas at tank if required.

•

Turn the power switch to “ON” position.

•

Adjust the thermostat set point to call for heat.

•

Observe the gas supply pressure as the burner fires at

100% of rated input. Supply pressure is to remain

stable.

•

Ensure inlet pressure is within specified range. Minimum

and maximum gas supply pressures are specified in

Table 10.

•

If gas pressure is out of range, contact the gas utility,

gas supplier, qualified installer or service agency to

determine necessary steps to provide proper gas

pressure to the control.

•

If gas supply pressure is within normal range, proceed

to remove gas manometer and replace pressure tap

fittings in the gas piping to the appliance. Turn the

power switch to “OFF” position.

•

Turn on gas supply at the manual valve; turn on LP gas

at tank if required.

•

Turn the power switch to “ON” position.

•

Adjust the thermostat temperature set point to the

desired water temperature so the appliance will call for

heat.

•

Check appliance performance by cycling the system

while you observe burner response. The burner should

ignite promptly. Flame profile should be stable, see

section 11.2, Visually Check Main Burner Flames. Turn

system off and allow burner to cool, then cycle burner

again to ensure proper ignition and flame

characteristics.

Summary of Contents for DMC 753

Page 20: ...16 ...

Page 63: ...59 PART 14 EXPLODED VIEW PARTS LIST DYNAMAX WALL HUNG ...

Page 64: ...60 DYNAMAX FLOOR MOUNT ...

Page 71: ...67 PART 15 ELECTRICAL DIAGRAMS 15 1 DM 80 250 INTERNAL WIRING DIAGRAM WALL HUNG MODELS ...

Page 72: ...68 15 2 DM 210 750 INTERNAL WIRING DIAGRAM FLOOR MOUNT MODELS ...