55

PART 10 INSTALLATIONS

WARNING

Before starting the boiler, smell near the floor and around

the boiler for any gas odours or any unusual odour.

Remove the stainless steel jacket and smell the interior of

the boiler. If there is any sign of a gas leak, do not proceed

with startup. Repair all the leaks before attempting to start

the boiler.

WARNING

Propane boilers ONLY – Your local propane supplier adds

an odorant to the propane gas to allow for propane gas leak

detection. In some cases, the added odorant can fade and

the gas may not give off any noticeable odour. Before

startup have the local propane supplier check for the

correct odorant level in the gas.

10.1

CHECKING THE INSTALLATION

•

Inspect the connections for water, gas and electricity.

•

Inlet gas pressure must be a minimum of 3” W.C. for

natural gas and 11” W.C. for propane.

•

With the boiler off, open the main gas supply valve and

vent the trapped air from the piping leading to the

boiler. Confirm that all gas connections to the heater

are tight and that there are no missing test plugs.

Refer to Section 8.1 Setting the Correct Combustion of the

manual for recommendations on setting combustion

characteristics

10.2

CHECKING THE CONSTRUCTION

•

Check the boiler wiring to see that it agrees with the

wiring diagram supplied.

•

Confirm that all terminal strips and field connections

are identified.

•

Confirm that the DynaMax HS Controller control is set

in the proper mode. In remote mode an external

controller determines the set point and the stage

contacts on the DynaMax HS Controller are always

closed. Auto reset limits are fixed in all Modes.

•

With the boiler running, check for flue gas leaks along

the inner cabinet joints and around the flue outlet.

•

Repair any leaks prior to proceeding to the next step.

•

At the factory, adjustments were made to achieve

proper input and acceptable burner performance at full

input and at minimum input.

10.3

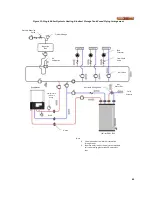

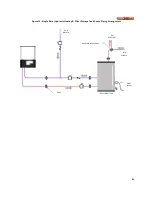

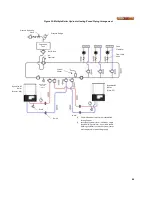

HEATING BOILER INSTALLATIONS

Before beginning the installation, consult local codes for

specific plumbing requirements. The installation should

have unions and valves at the inlet and outlet of the

appliance so it can be isolated for service. An air separation

device must be supplied in the installation piping to

eliminate trapped air in the system. Locate a system air

vent at the highest point in the system. The system must

also have a properly sized expansion tank installed.

Typically, an air charged diaphragm-type expansion tank is

used. The expansion tank must be installed close to the

boiler and on the suction side of the system pump

(appliance Inlet) to ensure proper operation. Caution: This

appliance should not be operated at less than 12 PSIG

cold. Pressure will rise when hot. Expansion tank sizing will

determine the pressure when the system is hot. Do not

operate the system at less than 18-20 PSIG when hot.

Water piping must be supported by suitable hangers or

floor stands, NOT by the appliance. Pipe systems will be

subject to considerable expansion and contraction. Pipe

supports could allow the pipe to slide resulting in noise

transmitted into the system. Padding is recommended. The

boiler pressure relief valve must be piped to a suitable floor

drain. See Section 4.11.

10.4

INSPECT & RECHARGE CONDENSATE

COLLECTION/NEUTRALIZING

RESERVOIR

1) Before starting the unit inspect the condensate

reservoir in the DynaMax HS making sure the

collection box is intact.

2) Remove screw holding lid on to condensate collection

box. Remove lid from the condensate collection box

3) Examine neutralizer medium and refill as necessary

with fresh medium

4) Fill with fresh water until the water begins to flow out of

drain

5) Re-install the lid and hold-down screw on the

condensate collection box.

WARNING

The condensate collection box must be filled with water to

prevent flue gas emissions from escaping during boiler

operation.

CAUTION

A leak in a boiler “System” will cause the fill system to

introduce fresh water constantly, which may cause the

tubes to accumulate a line/scale build up. Lime/scale

buildup leading to heat exchanger failure is NOT covered

by warranty.

10.5

WATER CONNECTIONS

System pipe size must be in accordance with Table 10

(depending on model) and, between supply and return

lines, must not exceed 50 feet of equivalent length.

Connection sizes at the heater are given in Tables 3 & 5.

Any reduction in recommended pipe size may decrease

flow resulting in high temperature rise across the heat

exchanger, boiler noise, flashing to steam and non-

warrantable heat exchanger damage.

10.6

PIPING LENGTHS

The appliance circulator provides the water flow from the

primary boiler piping, through the boiler and back to the

primary system. Pipe diameter and length are critical to

ensure proper flow through the boiler.

The secondary loop piping to and from the appliance must

have a fully ported ball valve installed in both the supply

and return side piping and will be used for isolation only.

The ball valves must be the same diameter as the installed

piping. If flow control is required, other means of flow

control such as globe valve or flow setter should be used.

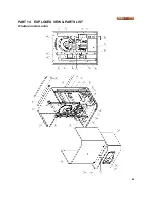

Summary of Contents for DynaMax DMH081

Page 2: ......

Page 68: ...65 PART 14 EXPLODED VIEW PARTS LIST DYNAMAX HS WALL HUNG...

Page 69: ...66 DYNAMAX HS FLOOR MOUNT...

Page 76: ...73 PART 15 ELECTRICAL DIAGRAMS 15 1 DM 80 299 INTERNAL WIRING DIAGRAM...

Page 77: ...74 15 2 DM 399 800 INTERNAL WIRING DIAGRAM...

Page 78: ...75...