57

For example in some cases it may be the bath tub

and in some cases it may be the clothes washer.

3) Allow the DynaMax HS to fire up and reach full fire

under

maximum

hot

water

load

demand

conditions.

4) Observe the outlet water temperature and close

the tuning valve gradually as outlet temperature

starts to drop. Allow the system to reach

equilibrium between adjustments to the tuning

valve.

5) Once the tuning valve is properly set, outlet

temperatures will never drop below

desired minimum temperature.

6) Seal stem of tuning valve with silicone to prevent

unauthorized tampering.

10.10 TEMPERATURE RISE AT FULL FIRING

RATE

1) The pump must run continuously when the burner is

firing.

2) With the pump running and the burner in the off cycle,

the inlet temperature and outlet temperature readings

on the DynaMax HS Control Panel should read

approximately the same temperatures.

3) Turn the appliance on and allow time for the

temperature to stabilize. Check the temperature rise

when the burner is firing at 100% of rated input.

4) Compare the temperature rise on the Control Panel

with the required temperature rise at the required flow

rate on Tables 20 and 21.

5) Should adjustment be needed, proceed as follows:

If the temperature rise is too high, the water velocity is

too low. Adjust as follows:

1) Check for flow restrictions. Check for debris in strainers

2) Check diameter and equivalent length of the piping

between the storage tank and hot water heater.

3) Be sure the pipes between the hot water heater and

storage tank are not more than a total of 50 equivalent

feet between supply and return lines. If maximum

equivalent length for the specified pipe diameter is

exceeded, larger diameter pipe may have to be

installed to achieve correct flow and temperature rise.

4) Be sure all valves are open between the hot water

heater and the storage tank. Ensure that all ball valves

are fully ported.

5) Check the pump to be sure it is running properly and

that the pump motor is running in the proper direction.

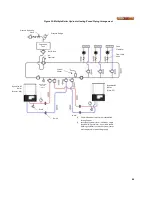

6) Common manifold piping for multiple unit installations

will require larger minimum pipe sizes and tank

circulating tapping to ensure proper flow.

The required temperature rise and the recommended pump

size are based on the heating of potable water with normal

hardness within a typical range of 7.5 to 17.0 grains per

gallon. Consult the factory when heating potable water

exceeding these specifications. Damage to the heat

exchanger as a result of scaling or corrosive water

conditions in non-warrantable.

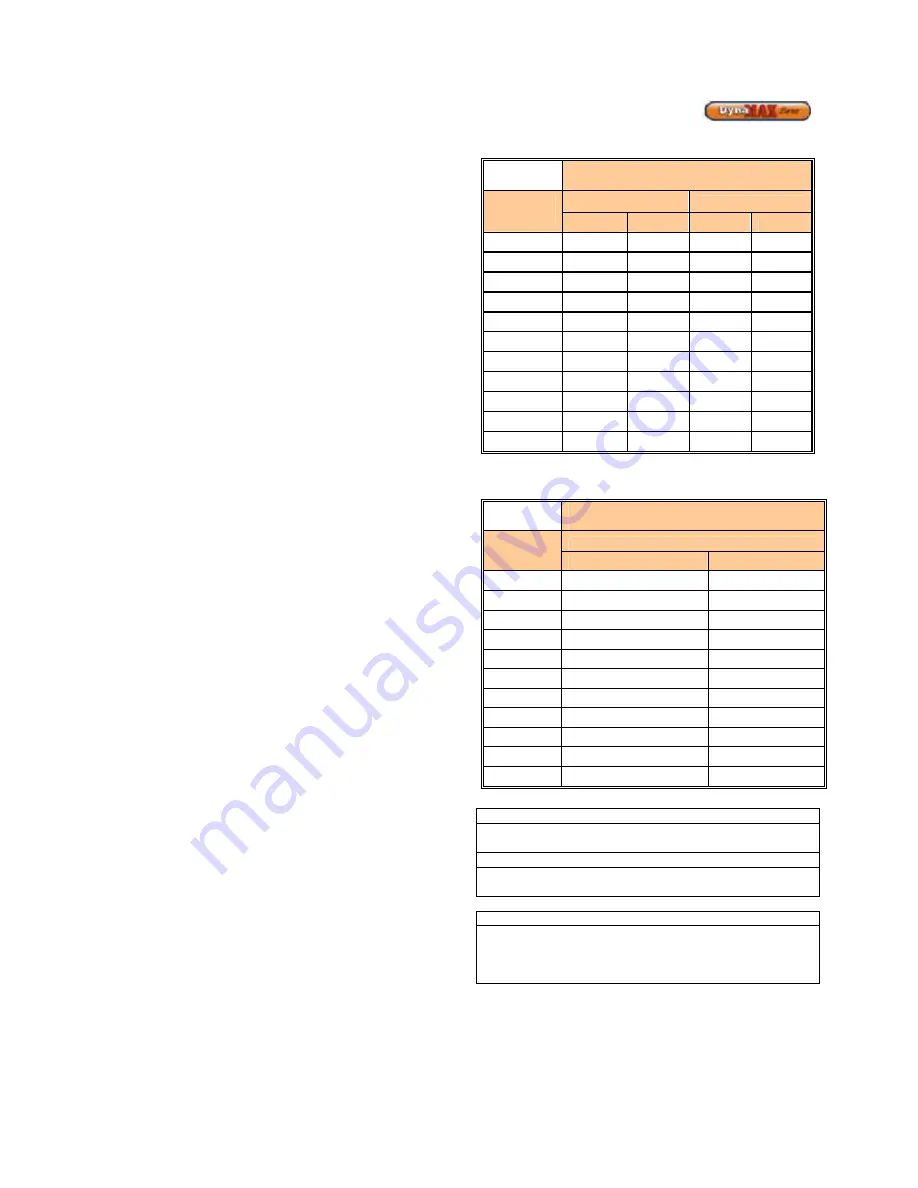

Table 20: Temperature Rise across Heat Exchanger

(Hydronic Heating)

TEMPERATURE RISE ACROSS HEAT

EXCHANGER

MODEL

[BTU/hr]

30

o

F (16.7

o

C)

35

o

F (19.4

o

F)

USGPM

∆

P-Ft.

USGPM

∆

P-Ft.

80,000

5.0

8.2

4.3

6.2

100,000

6.3

12.3

5.4

9.4

150,000

9.5

10.4

8.1

7.8

199,000

12.6

7.2

10.8

5.8

250,000

15.8

11.5

13.5

8.7

299,000

18.9

9.3

16.2

7.0

399,000

25.2

8.4

21.6

6.3

500,000

31.5

9.2

27.0

6.9

600,000

38.8

17.5

32.0

11.8

700,000

45.3

18.2

40.0

14.4

800,000

51.8

23.5

43.0

16.0

Table 21: Temperature Rise across Heat Exchanger

(DHW)

TEMPERATURE RISE ACROSS HEAT

EXCHANGER

MODEL

[BTU/hr]

20

O

F (11.1

o

C)

USGPM

∆

P-Ft.

80,000

7.5

11.5

100,000

9.4

26.9

150,000

14.0

27.8

199,000

19.2

25.9

250,000

23.5

28.3

299,000

28.8

25.8

399,000

38.4

23.9

500,000

48.6

29.4

600,000

57.6

34.2

700,000

70.4

40.0

800,000

77.6

43.2

CAUTION

Temperature rise cannot be adjusted when the burner is

firing at less than 100% of input rate.

CAUTION

Adequate care MUST be taken to prevent potential scald

injury when storing water at 140°F (60°C) and hotte r.

WARNING

Should overheating occur or the gas supply fail to shut off,

do not turn off or disconnect the electrical supply to the

pump, instead, shut off the gas supply at a location external

to the appliance

Summary of Contents for DynaMax DMH081

Page 2: ......

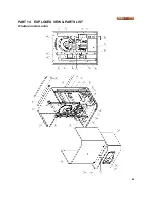

Page 68: ...65 PART 14 EXPLODED VIEW PARTS LIST DYNAMAX HS WALL HUNG...

Page 69: ...66 DYNAMAX HS FLOOR MOUNT...

Page 76: ...73 PART 15 ELECTRICAL DIAGRAMS 15 1 DM 80 299 INTERNAL WIRING DIAGRAM...

Page 77: ...74 15 2 DM 399 800 INTERNAL WIRING DIAGRAM...

Page 78: ...75...