76

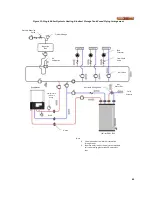

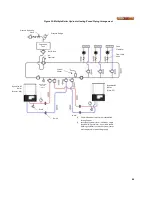

15.2

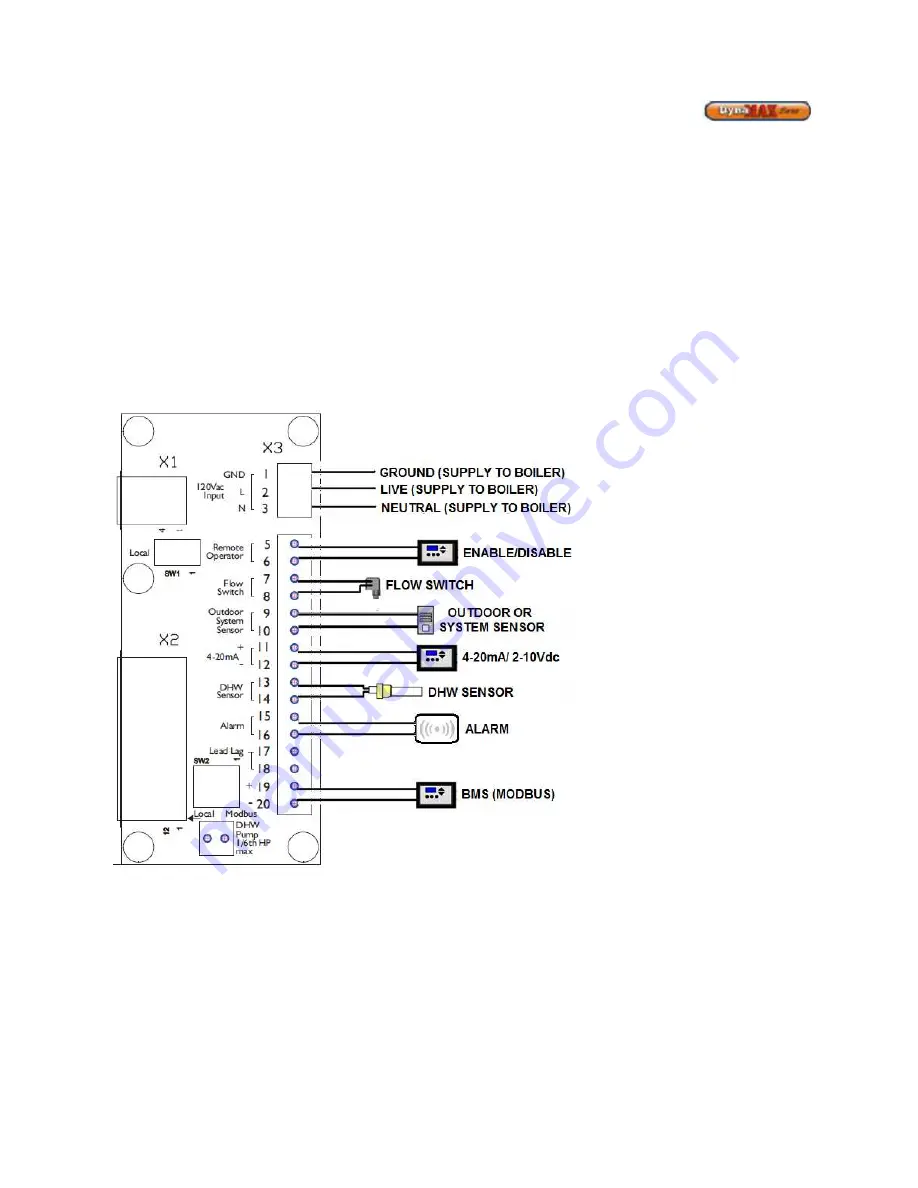

FIELD WIRING

All wires being placed into the terminal block should be horizontal for at least an inch to ensure sufficient electrical conductivity.

15.2.1

System Sensor

The temperature of the primary return can be controlled by installing a system sensor. The system sensor must be used in all

lead lag modes, and must be enabled through the DynaMax HS controller.

15.2.2

Lead Lag Setup

To setup a lead lag system a master boiler must be chosen, and the other boilers connected to it in this system are designated

as slaves through sequential Modbus addresses.

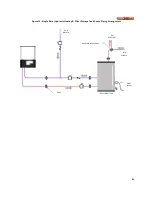

Connect the system sensor to the master boiler. The master boiler will use the water temperature in the primary loop to control

the operation of the lead lag setup.

If outdoor reset is desired, the outdoor sensor needs to be connected to the Outdoor Sensor location on the DynaMax HS

terminal board on boiler 2 (B-2). If the outdoor sensor is not connected to the Master boiler the DynaMax HS Controller will

maintain a fixed water temperature that is programmed into the control.

If a remote enable signal is available, it needs to be connected to the Remote Operator terminals on the DynaMax HS terminal

board. If the boiler is required to run continuously the switch can be placed in the ‘Local’ position.

Summary of Contents for DynaMax DMH081

Page 2: ......

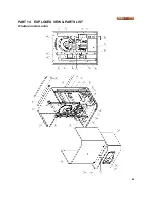

Page 68: ...65 PART 14 EXPLODED VIEW PARTS LIST DYNAMAX HS WALL HUNG...

Page 69: ...66 DYNAMAX HS FLOOR MOUNT...

Page 76: ...73 PART 15 ELECTRICAL DIAGRAMS 15 1 DM 80 299 INTERNAL WIRING DIAGRAM...

Page 77: ...74 15 2 DM 399 800 INTERNAL WIRING DIAGRAM...

Page 78: ...75...