PARTS TO BE INSTALLED

rbl2011-002-010_a

TYPICAL

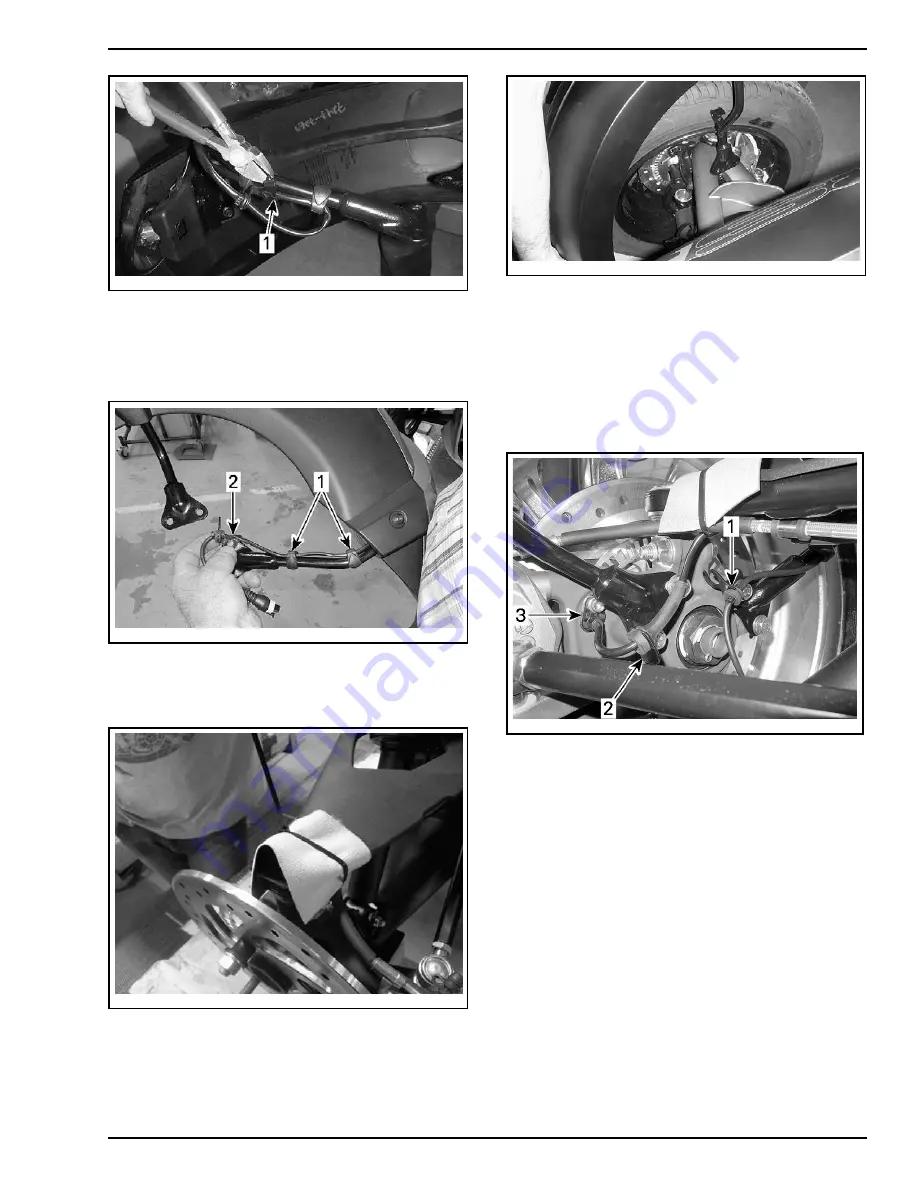

1. Locking tie

2. Ensure proper position of fender wiring har-

ness.

NOTE:

LH illustrated, RH similar.

rbl2014-004-048_a

1. Wiring harness clamps

2. Wiring harness bracket

NOTE:

Do not remove protection from suspension

arms.

rbl2013-004-002_a

TYPICAL

3. Position front fender on vehicle.

rbl2011-002-011

TYPICAL

4. Install 4 M8x 20 hexagonal flange screws

loosely to hold the fender in its position.

NOTE:

Be sure to install the fender light harness

and ABS harness brackets as illustrated. Do not

torque screws at this time.

NOTE:

Left side fender installation illustrated,

right side similar.

rbl2014-004-049_a

1. Fender light harness bracket, top screw, forward fender support

2. ABS harness bracket, lower screw, rear fender support

3. ABS sensor

5. Connect fender light connector.

NOTE:

Make sure harnesses are properly secured

through cable grommet in upper suspension arm.

PREDELIVERY

2014-3

21 / 41