34

ENGLISHENGLISH

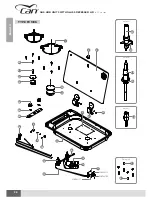

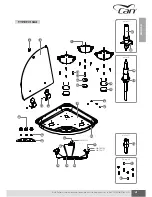

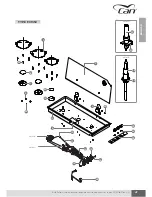

GAS HOB UNITS WITH GLASS RECESSED LID

▪

FC series

GAS CONNECTION

ATTENTION!

Before setting up the connection, make sure that the gas system and the installation rooms are

suitable for the purpose and comply with the standards in force in the Country of installation.

Refer to the specific technical standards regarding conformity of gas systems (LPG) for the

household (UNI CIG 7131 and 7129), nautical ( UNI EN ISO 10239) and recreational vehicles

(UNI EN 1949) sectors.

Before connecting the gas, check that:

▪

the supply line is free from obstructions and has a sufficient flow rate to guarantee correct operation

of the appliance;

▪

there is a suitable pressure regulator/reducer compliant with the gas categories used on the appliance

immediately downstream of the gas cylinder or container feeding the system;

▪

a gas shut-off valve or a valve disconnecting the system is installed on the supply line, downstream

of the regulator and immediately upstream of the appliance being connected, in a place which can

easily be accessed and inspected (

Please note:

this valve must always be shut during installation and

maintenance on the appliance).

ATTENTION!

Make sure that the type of gas feeding the appliance is among those allowed and listed in the

instruction booklet (see paragraph “Gas categories”).

CAN S.r.l. declines any liability for incorrect connections, not carried out in a workmanlike manner or

performed by non-professionally qualified individuals.

GAS CATEGORIES

The appliance was designed for correct operation only with the types of gas categories and operating

pressures listed below:

gas

category

and

country

of

destination

name

of

gas

operating

pressure

I3B/P (30)

AT-BE-DE-DK-FI-GB-NL-NO-PT-SE-SI

Butane (G30)

Propane (G31)

30 mbar

30 mbar

I3+ (28-30/37)

BE-CH-ES-FR-GB-IE-IT-PT-SI

Butane (G30)

Propane (G31)

28 - 30 mbar

37 mbar

CONNECTION PIPE REQUIREMENTS

ATTENTION!

The appliance must be connected to the gas pipeline by means of a suitable connection pipe

making use of certified sealed fittings of the most suitable type for the application.

It is possible to use flexible connection hoses. They must:

▪

always be able to be inspected,

▪

be protected against contact with hot parts (e.g. burner cups),

▪

be protected from the movable parts of the recessing (drawers, doors, etc.),

▪

have a length which complies with the technical standards for each sector of reference.

Avoid any type of mechanical stress on the flexible hoses during installation and use (protection against

traction, twisting, crushing, etc.).

ATTENTION!

Perform maintenance and periodically replace the flexible hose within the expiration date

written on the sheath. Do not use expired or damaged flexible hoses by any means.

Summary of Contents for FC Series

Page 62: ......