www.canadiansolar.com

| 9

the racking system in compliance with all local

electrical codes and regulations. Please refer to the

racking system user instructions.

6.0

MOUNTING INSTRUCTIONS

The applicable regulations pertaining

to work safety, accident prevention and

securing the construction site must be

observed. Workers and third party

personnel shall wear or install fall arrest equipment.

Any third party need to be protected against injuries

and damages.

· The mounting design must be certified by a regis-

tered professional engineer. The mounting design

and procedures must comply with local codes and

requirements from all relevant authorities.

· Each module must be securely fastened at a mini-

mum of 4 points on two opposite sides. The clamps

should be positioned symmetrically. Canadian Solar

Inc. recommends mounting rails with a minimum

width of 40 mm for ±2400 Pa load and a minimum

width of 60 mm for +5400 Pa / -2400 Pa load.

· Install and tighten the module clamps to the moun-

ting rails using the torque stated by the mounting

hardware manufacturer. System designer and

installer are responsible for load calculations and

for proper design of support structure. It is recom-

mended to use a torque wrench for installation.

Tightening torques should respectively be within

17~23 Nm (12.5~17.0 ft-lb) for M8x1.25-Grade 8.8

(5/16”-18 Grade B7) galvanized or A2-70 stainless

steel coarse thread bolts, depending on bolt class.

The yield strength of bolt and nut should not be

less than 450 MPa.

· Use appropriate corrosion-proof fastening materi-

als. All mounting hardware (bolts, spring washers,

flat washers, nuts) should be hot dip galvanized or

stainless steel.

· Clamp material should be anodized aluminum alloy

or steel of appropriate grade. One buffer rubber

material (Recommended material is EPDM) must be

added between the clamp and the glass.

· Canadian Solar Inc. warranty may be void in cases

where improper clamps or unsuitable installation

methods are found. When installing clamps, take

measures so as:

1. Not to bend the laminate excessively.

2. Not to cast shadow on the cells.

3. Not to damage or scratch the surface of the glass.

4. To ensure the clamps overlap the module by

13 mm to 15 mm.

5. To ensure the thickness of the clamps is at

least 3 mm.

· Clamp positions are of crucial importance for the

reliability of the installation, the clamp centerline

must only be positioned within the authorized posi-

tion ranges indicated in ANNEX B, depending on the

configuration and load.

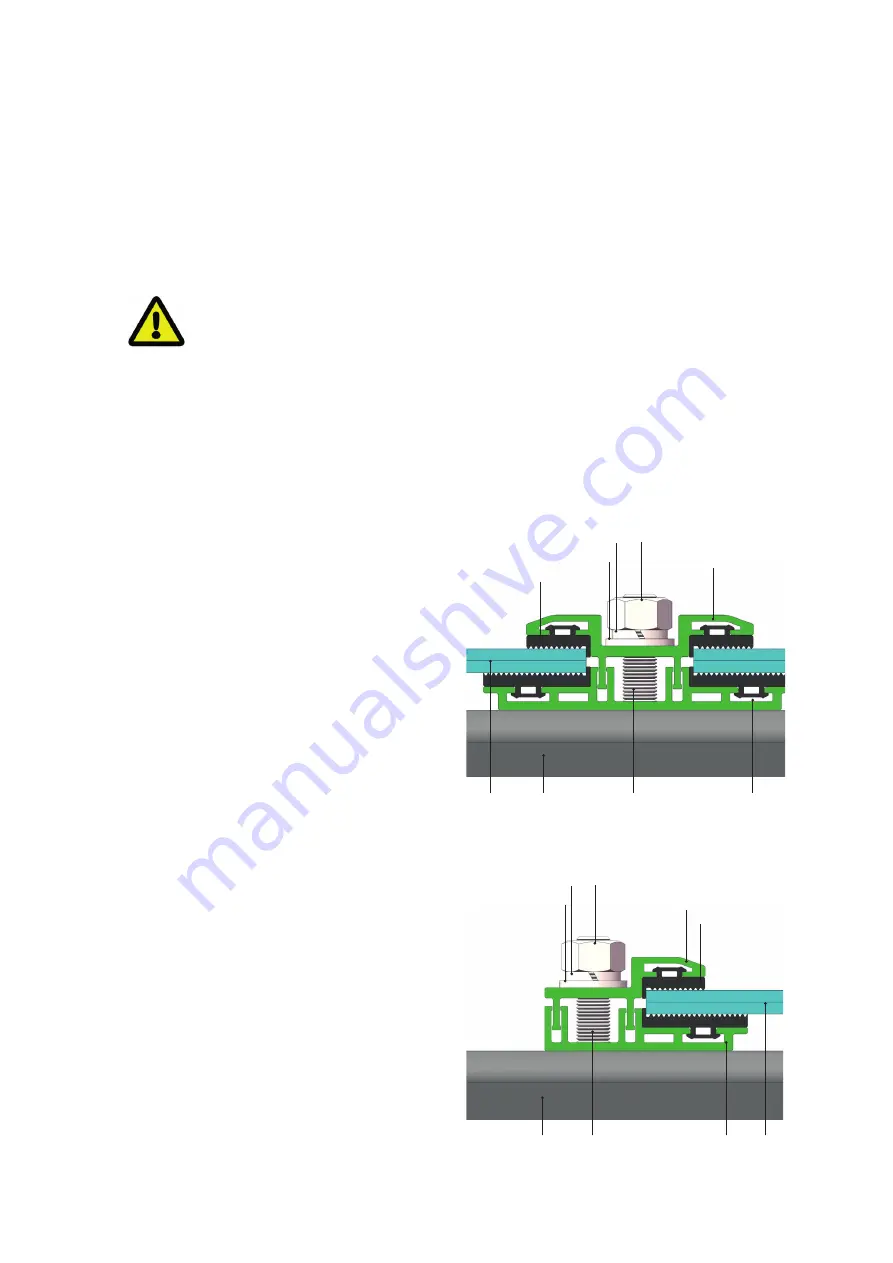

Nut

Rail

Glass

Spring washer

Flat washer

Rubber

Top Middle Clamp

Bolt Bottom Middle Clamp

Nut

Rail

Glass

Spring washer

Flat washer

Rubber

Top End Clamp

Bolt

Bottom End Clamp

MIDDLE CLAMP:

END CLAMP: