| 14

EN-Rev IM/GN-EN/1.0 Copyright © January, 2023. CSI Solar Co., Ltd.

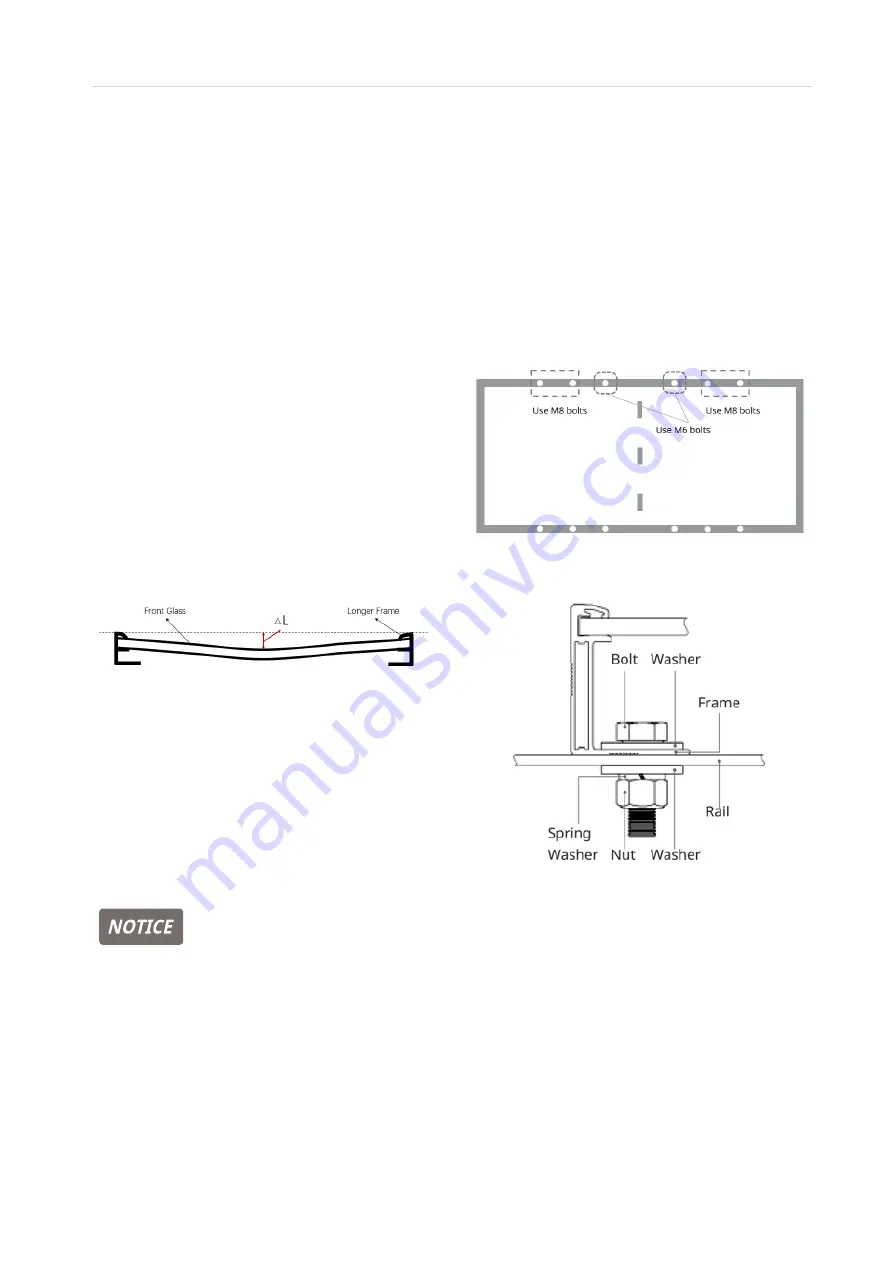

followed. Different recommendations from specific clamping

hardware suppliers should prevail. 2) The yield strength of

bolt and nut should not be less than 450 MPa.

Clamp material should be anodized aluminum alloy or

stainless steel of appropriate grades.

Clamp positions are of crucial importance for the reliability

of the installation, the clamp centerline must only be

positioned within the authorized position ranges indicated

below, depending on the configuration and load.

The laminate of the PV modules will sink downward to

varying degrees due to gravity, with the center of module

being the maximum deflection position. While using bolting

or clamping mounting method or insertion system, the

maximum allowable deflection (ΔL shown in the picture

below) is 20 mm (in the absence of external forces caused

by, for example, wind and snow). Note that applying

pressure to the module surface during storage,

transportation and installation will lead to more severe

deflection.

6.1 MOUNTING METHOD: BOLTING

The mechanical load test with these mounting methods

were performed according to IEC 61215.

Modules should be bolted to supporting structures through

the mounting holes in the rear frame flanges only.

Each module must be securely fastened at a minimum of 4

points on two opposite sides.

Suitable bolt length should be chosen

based on actual module frame height. For

double glass module with 30 mm frame

height, our recommended maximum bolt length is 20 mm

in order to properly insert the bolts through the mounting

hole. The system designer is responsible to check that the

racking supplier specified bolt length complies with above

requirement and will not affect installation.

In areas with heavy wind loads, additional mounting points

should be used. The system designer and the installer are

responsible for correctly calculating the loads and ensuring

that the supporting structure meets all the applicable

requirements.

Bolt locations on the module, where M6 bolts are used

only in single-axis tracker

Mounting method: Bolting

Modules should be bolted at the following hole locations

depending on the configuration and loads, which is shown

in table 3.