| 33

EN-Rev IM/GN-EN/1.0 Copyright © January, 2023. CSI Solar Co., Ltd.

The coating should be applied in a dry atmosphere (at least 24 hours) under the following conditions:

relative humidity RH

≤

75%, ambient temperature T>5°C.

Maintenance

period

Three months

Five years

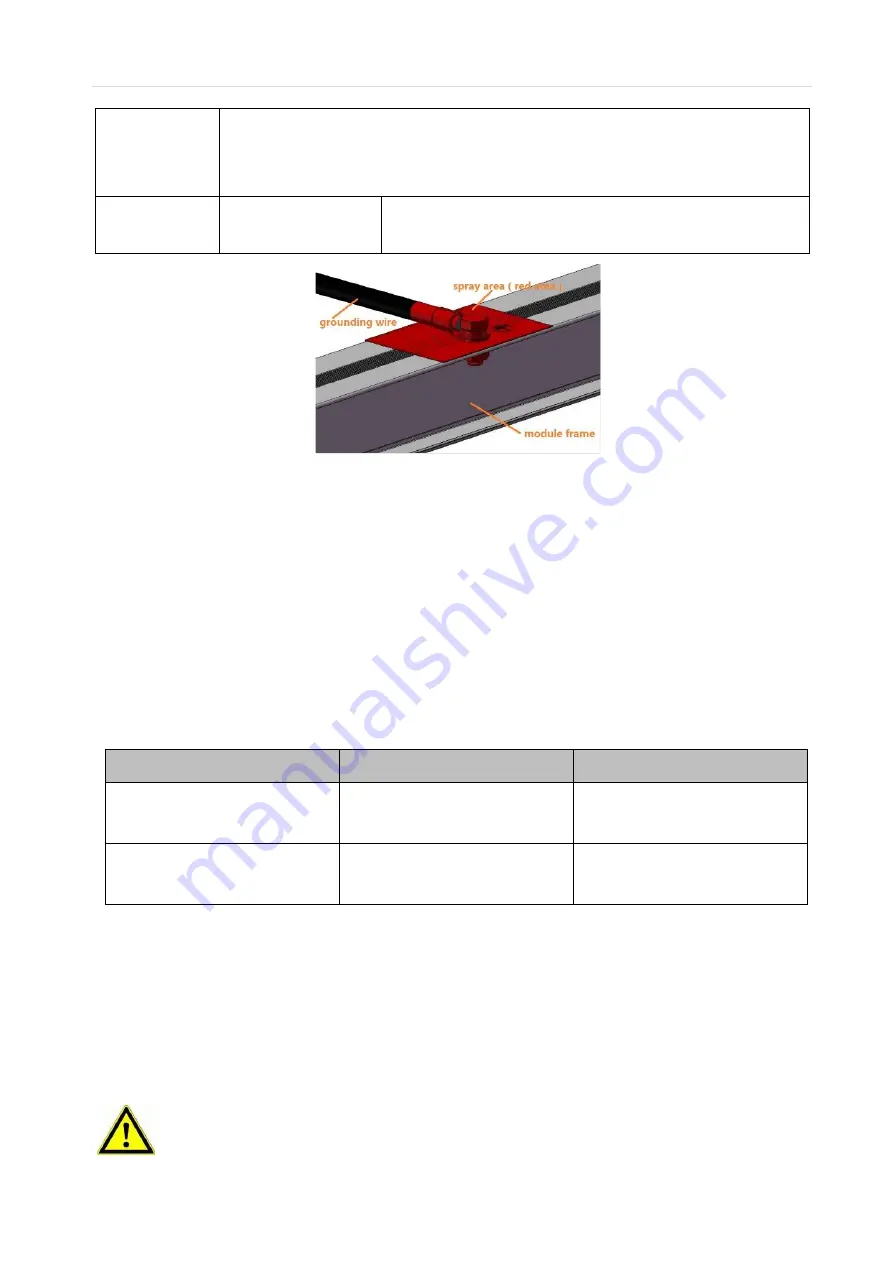

C.3.0: ANTI-CORROSION SUGGESTIONS FOR THE

RACKING SYSTEM

Suggestions for the racking system are provided below.

The warranty does not cover the damage to the mounting

system caused by corrosion if the mounting system is not

provided by Canadian Solar. The requirements below apply

to two main mounting systems: aluminum alloy-based

racking for rooftops and galvanized steel-based structures

for ground-mounted solar farms. To prevent salt-mist

corrosion, Canadian Solar requires strict compliance with

the following principles:

Use approved corrosion-resistant materials (e.g. stainless

steel SUS 316 or carbon steel with a hot-dip galvanized

coating) for any racking or BOS components used in

coastal areas.

Process specifications for the different components must

comply with relevant international anti-corrosion standards.

Minimum coating thicknesses for hot-dip galvanized and

anodizing oxide components must comply with the

standard minimum requirements stipulated in JIS8641 and

JIS8601.

Process

Minimum coating thickness

Standard

Hot-dip galvanizing

(carbon steel)

HDZ55 (76um)

ISO 1461

JIS8641

Anodizing oxide

(aluminum alloy)

AA20 (20um)

ISO 7599

JIS8601

Use mounting components that contain the same metals or

metals with a similar electrochemical potential. The metal’s

coating should also be taken into account. There may be a

big difference between the electrochemical potentials of

two different coating materials.

C.4.0: Precautions and General Safety

Before installing any modules, contact the

appropriate authorities to obtain any relevant

approvals and learn of any site, installation and inspection

requirements.

When applying coating materials, workers must follow

applicable health and safety legislation and apply all

respective preventive and proactive measures described

within.

C.5.0: LIMITATION OF LIABILITY

Canadian Solar shall not be held responsible for damages