| 5

EN-Rev IM/GN-EN/1.0 Copyright © January, 2023. CSI Solar Co., Ltd.

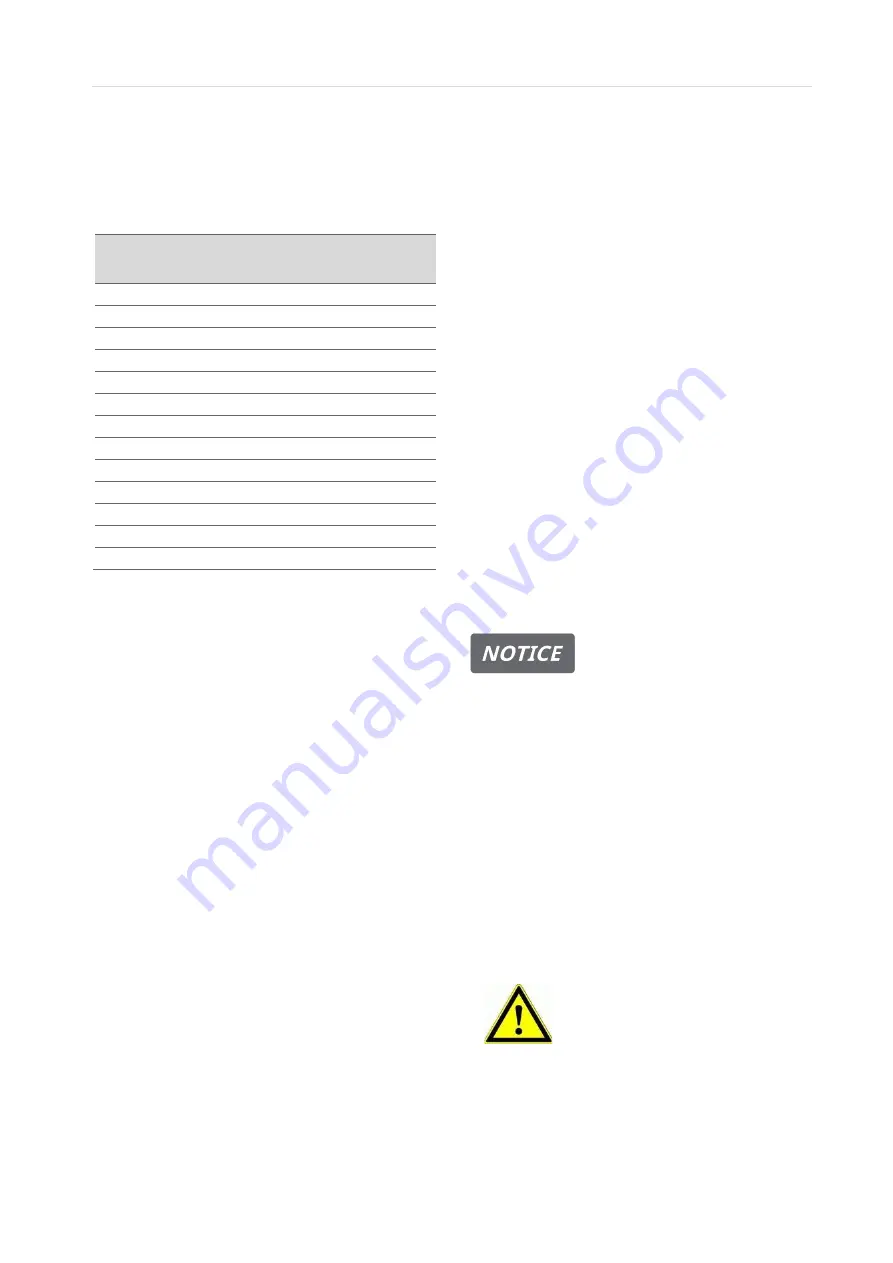

should be multiplied by 1.25, and a correction factor should

be applied to the open-circuit voltage (see Table 1 below),

when determining component ratings and capacities.

Table 1: Low temperature correction factors for open-

circuit voltage

Lowest Expected

Ambient Temperature

(°C/°F)

Correction Factor

24 to 20 / 76 to 68

1.02

19 to 15 / 67 to 59

1.04

14 to 10 / 58 to 50

1.06

9 to 5 / 49 to 41

1.08

4 to 0 / 40 to 32

1.10

-1 to -5 / 31 to 23

1.12

-6 to -10 / 22 to 14

1.14

-11 to -15 / 13 to 5

1.16

-16 to -20 / 4 to -4

1.18

-21 to -25 / -5 to -13

1.20

-26 to -30 / -14 to -22

1.21

-31 to -35 / -23 to -31

1.23

-36 to -40 / -32 to -40

1.25

Alternatively, a more accurate correction factor for the open-

circuit voltage can be calculated using the following formula:

𝐂

Voc

= 𝟏 − 𝜶

𝑽𝒐𝒄

× (𝟐𝟓 − 𝐓)

T (°C) is the lowest expected ambient temperature at the

system installation site.

α

Voc

(%/°C) is the voltage temperature coefficient of the

selected module (refer to corresponding datasheet).

OCPD rating selection should be done per the following

guidance, where the minimum OCPD rating possible is

determined by calculating the expected maximum circuit

current for the PV system, and the maximum OCPD rating

constrained by the IEC 61215: 2016 and UL 61730 standard

requirements for the certified PV modules.

Minimum string fuse rating < X ≤ Maximum string fuse

rating.

The maximum string fuse ratings can be found in datasheets

and nameplates for all the certified Canadian Solar module

types.

The minimum string fuse rating for compliance with NEC:

2017 code and IEC 62548: 2016 requirement is suggested

to be determined as follows:

Minimum string fuse rating = Isc

STC

x 1.25 x Max (1.175,

Impp

α

÷ Impp

STC

).

Impp

α

= the highest 3-hour current average resulting from

the simulated local simultaneous irradiances on the front

and rear sides of the PV array accounting for elevation and

orientation.

Isc

STC

= the listed short circuit current at 0% bifacial gain

on the PV module datasheet or nameplate label.

Impp

STC

= the listed MPP operating current at 0% bifacial

gain on the PV module datasheet or nameplate label.

An assembly, together with its overcurrent device(s), that is

listed for continuous operation at 100 percent of its rating

shall be permitted to be used at 100 percent of its rating, and

therefore shall not require the additional 1.25 multiplier.

Electrical calculations and design must be performed by a

competent engineer or consultant.

Please contact Canadian Solar’s technical support team for

additional information pertaining to engineering optimization

and approval of project specific module string lengths.

4 UNPACKING AND STORAGE

PRECAUTIONS

Modules should be stored in a dry and ventilated

environment to avoid direct sunlight and moisture. If

modules are stored in an uncontrolled environment, the

storage time should be less than 3 months and extra

precautions should be taken to prevent connectors from

being exposed to moisture or sunlight, like using connector

endcaps. Protect the package from damage. In any

circumstances, pallets with landscape-oriented module

packaging shall not be stacked vertically more than two

high; and for pallets with portrait-oriented module

packaging, stacking is not allowed.

When unloading module pallets from a

flatbed truck, please use a crane or a forklift

to remove the module pallets. When

unloading module pallets from containers, please use a

forklift to remove the module pallets from the container or

trailer. Do not move any pallets within the container or trailer