| 7

EN-Rev IM/GN-EN/1.0 Copyright © January, 2023. CSI Solar Co., Ltd.

Keep all electrical contacts clean and dry at all times.

Do not

expose the modules and its electrical contacts

(junction boxes, connectors) to any unauthorized chemical

substance (e.g. oil, lubricant, pesticide, petrol, white flower

oil, activating collaterals oil, mold temperature oil, machine

oil (such as KV46), grease (such as Molykote EM-SOL,

etc.), lubricating oil, anti-rust oil, stamping oil, butter

,

cooking oil, propyl alcohol, ethyl alcohol, essential oil,

bone-setting water, Tianna water, mold release agent (such

as Pelicoat S-6, etc.), glue and potting glue that can

generate oxime gas (such as KE200, CX-200, Chemlok,

etc.), TBP (plasticizer), cleaning agents, pesticide, paint

strippers, adhesives, antirust agent, disincrustant,

emulsifying agent, cutting oils and cosmetics, etc.) as

modules may incur damages. Please contact your

Canadian Solar representative for more detailed

requirements.

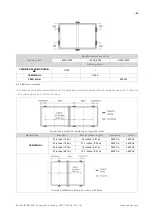

PRODUCT IDENTIFICATION

Each module has three identical barcodes (one in the

laminate under the front glass, the second on the rear side of

the module and the third on the frame) that act as a unique

identifier. Each module has a unique serial number containing

14 or 16 digits.

A nameplate is also affixed to the rear of each module. This

nameplate specifies the model type, as well as the main

electrical and safety characteristics of the module. It also

includes the barcode with the module unique serial number

as mentioned above.

5 MODULE INSTALLATION

PRECAUTIONARY

MEASURES

AND

GENERAL SAFETY

Prior to installing modules, please obtain

information about any requirements and necessary

approvals for the site, installation and inspection from the

relevant authorities.

Check applicable building codes to ensure that the

construction or structure (roof, facade, support, etc.) can

bear the module system load.

Canadian solar modules have been qualified for

Application Class A (equivalent to Safety Class II

requirements). Modules rated under this class should be

used in systems operating at voltage above 50V or power

above 240W, where general contact access is anticipated.

Canadian Solar double glass modules have been certified

as Type 29 according to UL 61730 and as Class C

according to IEC 61730-2 for fire performance. Single glass

monofacial modules have been certified as Type 1 or Type

2 according to UL 61730 and Class C according to IEC

61730-2. Please refer to the datasheet or the product

nameplate for the detailed types.

Consult your local authority for guidelines and

requirements for building or structural fire safety.

UL 61730 SYSTEM FIRE RATING REQUIREMENTS

The fire rating of this module is only valid when the product

is installed as specified in the mechanical mounting

instructions.

When installing the modules, ensure the assembly is

mounted over a fire-resistant roof covering rated for the

application.

Photovoltaic systems composed of UL 61730 certified

modules mounted on a UL 2703 certified mounting system

should be evaluated in combination with roof coverings in

accordance with UL 61730 standard, with respect to

meeting the same fire classification as the roof assembly.

Mounting systems with a System Fire Class Rating, tested

in conjunction with ‘type 1’, ‘type 2’ or ‘type 29’ fire rated

modules, are considered acceptable for using with

Canadian Solar modules, providing the mounting system

does not violate any other requirements of this manual.

Any mounting system limitations on inclination or

accessories required to maintain a specific System Fire

Class Rating should be clearly specified in the installation

instructions and UL 2703 certification of the mounting

system supplier.

ENVIRONMENTAL CONDITIONS

PV modules are intended for use in general open-air

climates, as defined in IEC 60721-2-1: Classification of

environmental conditions Part 2-1: Environmental

conditions appearing in nature-Temperature and humidity.

It is recommended that PV modules be installed in an

environment with ambient temperature ranging from -40 °C