| 9

EN-Rev IM/GN-EN/1.0 Copyright © January, 2023. CSI Solar Co., Ltd.

installation site. The highest yields are achieved when

sunlight shines perpendicularly onto the PV modules.

AVOID SHADING

Modules shall not be permanently shaded (including partial

shading, spot shading, even shading or uneven shading)

under any circumstances. Permanent shading includes

shading of the same cell, cell row, or module portion for

extended and repeated periods of time (e.g. more than 200

daylight hours over the warrantied service lifetime). Power

dissipated in fully or partially shaded cells will result in

power loss, reduced yield and can cause localized

overheating, which in turn may negatively impact the

module service lifetime. Permanent shading may cause

accelerated ageing of the encapsulation material and place

thermal stress on the bypass diodes. This would void the

module’s warranty unless properly mitigated through the

use of Module Level Power Electronic (MLPE) devices.

Regular maintenance is required to keep modules clean.

Particular measures should be taken to avoid permanent

shading from dirt or debris (e.g., plants, bird droppings,

etc.).

Do not install modules directly behind any object (e.g., tree,

antenna, etc.) to prevent occurrence of permanent shading.

Even temporary partial shading will reduce the energy yield.

A module can be considered to be unshaded if its entire

surface is free from shading all year round, including on the

shortest day of the year.

For optimizing the power generation of the rear side of

bifacial modules, obstacles between modules and the

mounting ground should be avoided as much as possible.

RELIABLE VENTILATION

Bifacial modules use direct, reflected, or diffuse sunlight on

the backside to generate additional power. Therefore,

bifacial modules are not suggested to be used in building

attached photovoltaic systems (BAPV).

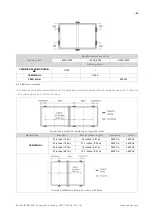

Sufficient clearance of at least 10.2 cm (4.0 in) between the

module bottom side and the surface of roof or wall needs

to be provided to allow cooling air to circulate around the

back of the module. This also allows condensation or

moisture to dissipate. In particular, the minimum clearance

of any modules applied in BWh area (please refer to Figure

A.3) should be determined in accordance with annex A.

According to UL 61730, any other specific clearance

required for maintaining a system fire rating should prevail.

Detailed clearance requirements pertaining to system fire

ratings must be provided by your racking supplier.

5.1 MODULE WIRING

CORRECT WIRING SCHEME

Cable management scheme should be reviewed and

approved by the EPC contractor. Required cable lengths

should be cross-checked and account for tracker structure

particularities e.g. bearing house gaps. If longer cables or

additional jumper cables are required, please contact

Canadian Solar’s sales representative in advance.