32

of 42

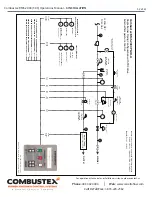

Combustex BMS-2000 [5.03] Operations Manual -

5. INSTALLATION

Phone:

403.342.4494

|

Web:

www.canaltaflow.com

For operational, technical or installation assistance, please contact us.

Call Us Toll Free:

1-855-226-2582

Combust

ex BMS

-2000 P&ID

-A

Single Bur

ner P

iping C

onfigur

ation with POC

Valv

e.

Ex

ter

nal T

emper

atur

e

Con

tr

ol

.

Not

e A:

S

af

et

y Shut

do

wn

Valv

e with POC c

omplian

t with

CSA ANSI Z21.21 / C

GA 6.5CI / C

GA 3.9 / F

M7412

Not

e B:

Z21.21 / CSA 6.5

Class 1 Div

. 2 Hazar

dous L

oca

tion

Dr

awing c

omplies with CSA B149.3-10 up t

o 5 MM Btuh.

E

12

TO 30

VDC PO

WER SUPPL

Y

REMO

TE ST

AR

T/ST

OP INPUT

BURNER FL

A

ME ST

ATUS OUTPUT

REMO

TE B

ATH

TEMPER

ATURE OUTPUT

REMO

TE B

ATH

TEMPER

ATURE SE

TPOINT INPUT

TS3 7&8

TS1 5&6, 7&8

TS7 7&8,

TS9 7&8

TS3 1&2

TS5 5&6

T/C

T/C

T/C

LLSD

HT

SD

AUX. BA

TH

HIGH TEMP

.

BA

TH L

OW LE

VEL

CONFIGUR

ABLE ADDERS

(see manual sec

tion 3.2)

BA

TH TEMP

.

SP

ARE

#1 TEMP

.

SP

ARE

#2 TEMP

.

(D

edica

ted t

o P

roc

ess

on V

ersion

5.032)

TS2 3&4

TS2 1&2

TS5 7&8

TS6 5&6

TS6 1&2

TS

2

7&8

TS

8

1&2

TS

4

7&8

TS

8

7&8

LPSD

#1

TS2 5&6

TS3 5&6

TS7 6

Ig

nit

er / P

ilot / FFSD

SE

T AS PER

PIL

O

T BURNER

REQUIREMENT

S

Pilot V

alv

e

Solenoid

See Not

e A

SSOV

Solenoid

See Not

e B

PIL

O

T #1

M

AIN #1

Relief V

alv

e

(if r

equir

ed)

SE

T AS PER

M

AIN BURNER

REQUIREMENT

S

SE

T AS PER

CONTR

OL V

AL

VE

REQUIREMENT

S

Speed C

on

tr

ol

Valv

e

Filt

er r

egula

tor set a

t

SSOV r

equir

emen

ts

M

ain T

emp

Con

tr

oller

T/C

CLEAN, DR

Y

FUEL GAS

SAFE

TY INTERL

OCKS

THERMOC

OUPLE INPUT

S

Indica

tion,

Temp

. C

on

tr

ol & SD

SSOV with

Proof of Closur

e

HPSD

#1

TS

4

5&6

M

ain C

on

tr

ol

Valv

e

E