FIBERGLASS FAN

M0066_FIBERGLASS FAN_02_22_2023

Page 4 of 10

Fans are designed to operate with simple on/off switches, or can be wired into sophisticated controls. Some fan models are designed to

run at variable speed while others are single speed only.

Varying a single speed fan will cause the motor to fail.

Fan labels should indicate whether or not fan is variable speed. If unsure contact a Canarm representative with the fan model number at

our head office.

OPERATION

MAINTENANCE

These fans are used in a variety of applications and therefore maintenance schedules will vary. In general no more than 1/16" of dirt build-

up should occur on blade, motor, guard, and louvers for proper fan operation and to prevent premature failure. The complete fan should

be washed down on a regular basis to maintain the high efficiency of the fan. Particular care should be taken to clean louvers, fan blades

front and back, and front guards for better air moving performance. The motor should be kept clean to prevent overheating and premature

failure. As with all mechanical equipment scheduled inspections should include checking that all hardware is secure and blade set screws

are tight. We suggest as a minimum, that this be done after every grow out, in livestock applications.

WARNING

MOTORS ARE EQUIPPED WITH AUTOMATIC OVERLOAD PROTECTION AND MAY RESTART

WITHOUT WARNING. ALWAYS DISCONNECT POWER BEFORE ATTEMPTING TO SERVICE.

WARNING:

VARIABLE SPEED FANS SHOULD HAVE THE MINIMUM SPEED SET TO OPEN THE FAN

LOUVERS A MINIMUM OF 1" TO ENSURE PROPER MOTOR COOLING AND PREVENT PREMATURE

MOTOR FAILURE.

Figure 3

SHUTTER TOP

PUSH DOWN

INTO NOTCH

WILL WRAP AROUND

THIS EDGE

Summary of Contents for FGI18

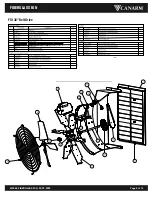

Page 6: ...FIBERGLASS FAN M0066_FIBERGLASS FAN_02_22_2023 Page 6 of 10 18 Direct Drive 1 2 3 4 5 6 7...

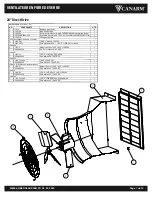

Page 7: ...FIBERGLASS FAN M0066_FIBERGLASS FAN_02_22_2023 Page 7 of 10 24 Direct Drive...

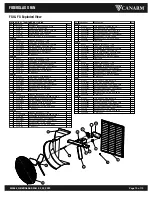

Page 8: ...FIBERGLASS FAN M0066_FIBERGLASS FAN_02_22_2023 Page 8 of 10 36 Direct Drive...

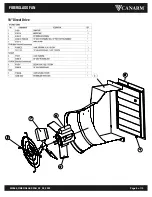

Page 9: ...FIBERGLASS FAN M0066_FIBERGLASS FAN_02_22_2023 Page 9 of 10 FGI 36 Belt Drive...