User’s Guide for All PLF Series Models

Congratulations on the purchase of your new High Performance Plastic Fan. This fan is made of materials that ensure

long lasting performance and is designed with features that make it one of the most efficient and easy to use and care

for fans available today.

Your fan comes completely assembled except for the metal turn clips that can be quickly assembled into the pre-drilled

holes around the outside flanges of the fan. All fans are tested for proper operation before leaving the factory. Your fan

should be installed into a wood frame. See Chart #1 for dimensions.

Rough Inside Opening Frame Dimension

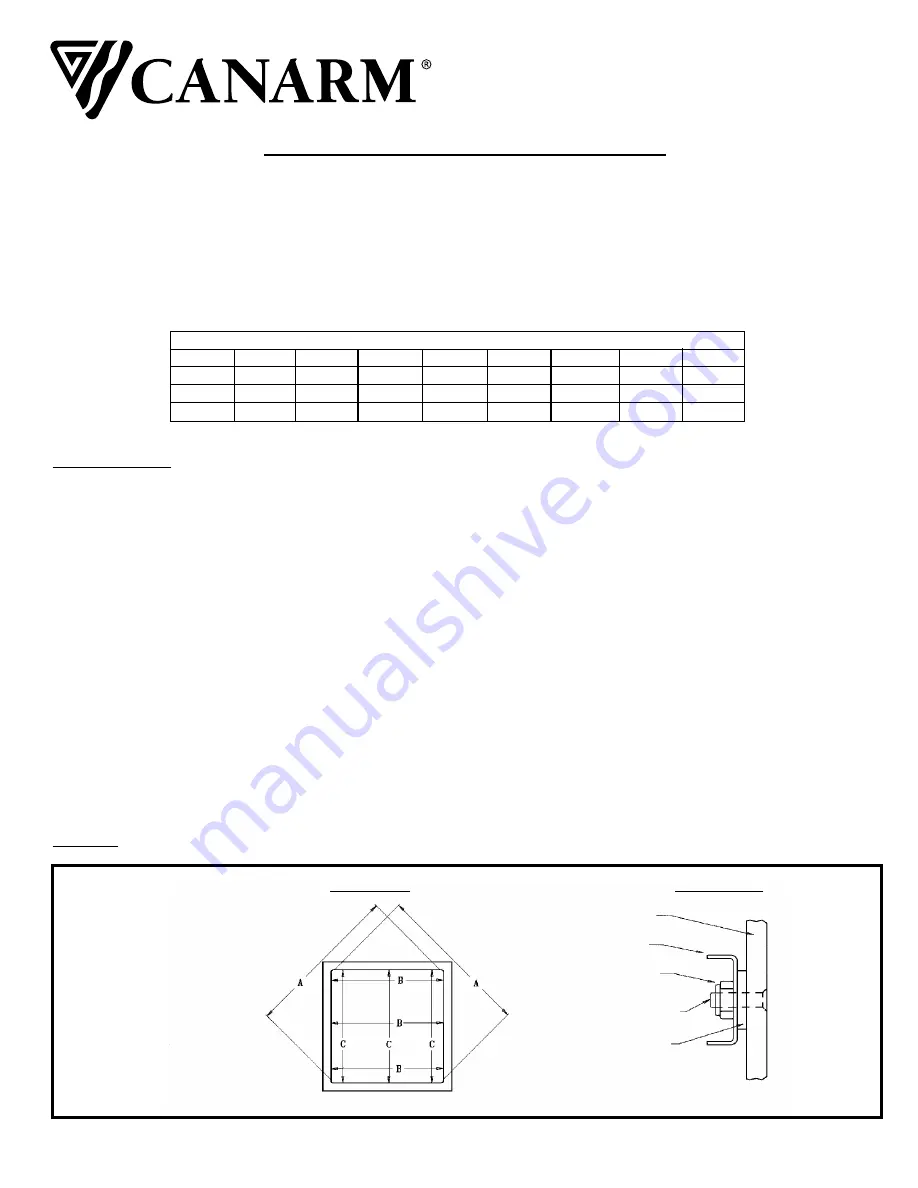

INSTALLATION

PLF36 Models

Remove the fan from the shipping pallet by removing the 6 screws holding the fan to the pallet. A hardware bag is

secured to the motor support arm. The hardware bag contains 8 turn clips, 8 nylon washers, 8 10-24 x 3/4" stainless

steel screws, and 8 nylon insert nuts. This hardware is for the turn clips that hold the shutter assembly in place.

Assemble the 8 turn clips to the pre-drilled holes. There are 3 holes down each side flange and 1 on each of the top

and bottom flanges. For each of the 8 turn clips insert the screw through the hole from the back of the flange, slide on

a nylon washer, then the clip, and thread the nut. Tighten the turn clips with a Phillips screw driver and a 3/8" socket

wrench. (see Figure 1-b).

PLF09 to PLF24 Models

Simply remove the fan from the carton and proceed to next section.

All Fan Models

With the shutter removed, slide the fan into the framed opening. Push the fan up against the top of the frame to be sure

the fan slopes downward for drainage to the outside. Secure the 4 corners with lag bolts. Secure the 4 sides being

sure the inside dimensions of the fan are consistent between flanges so that clips and shutters will operate correctly.

(see Figure 1-a) This will also ensure that the orifice, is not deformed which may cause the blade to hit the tunnel of the

fan.

Caution: If using expanding foam to insulate, make sure expansion pressure does not damage the housing.

Chart #1

Inside View of Fan

- Be Sure All Similar

Dimensions Are Equal

When Mounting Fan

Mounting

Fan Flange

Turn Clip

Hex Locknut

Machine Screw

Clip Detail

Figure 1-b

Figure 1-a

Nylon Washer

Model

H

W

PLF09

15.00"

15.00"

Model

H

W

Model

H

W

PLF12

15.00"

15.00"

PLF18

21.25"

21.25"

PLF16

19.25"

19.25"

PLF24

27.25"

27.25"

PLF14

17.25"

17.25"

PLF20

23.25"

23.25"

PLF36

40.25"

40.25"

PLF48

52.25"

52.25"

M0017 - Rev. 5 - Rev Date: 22/04/03

Page 2 of 5