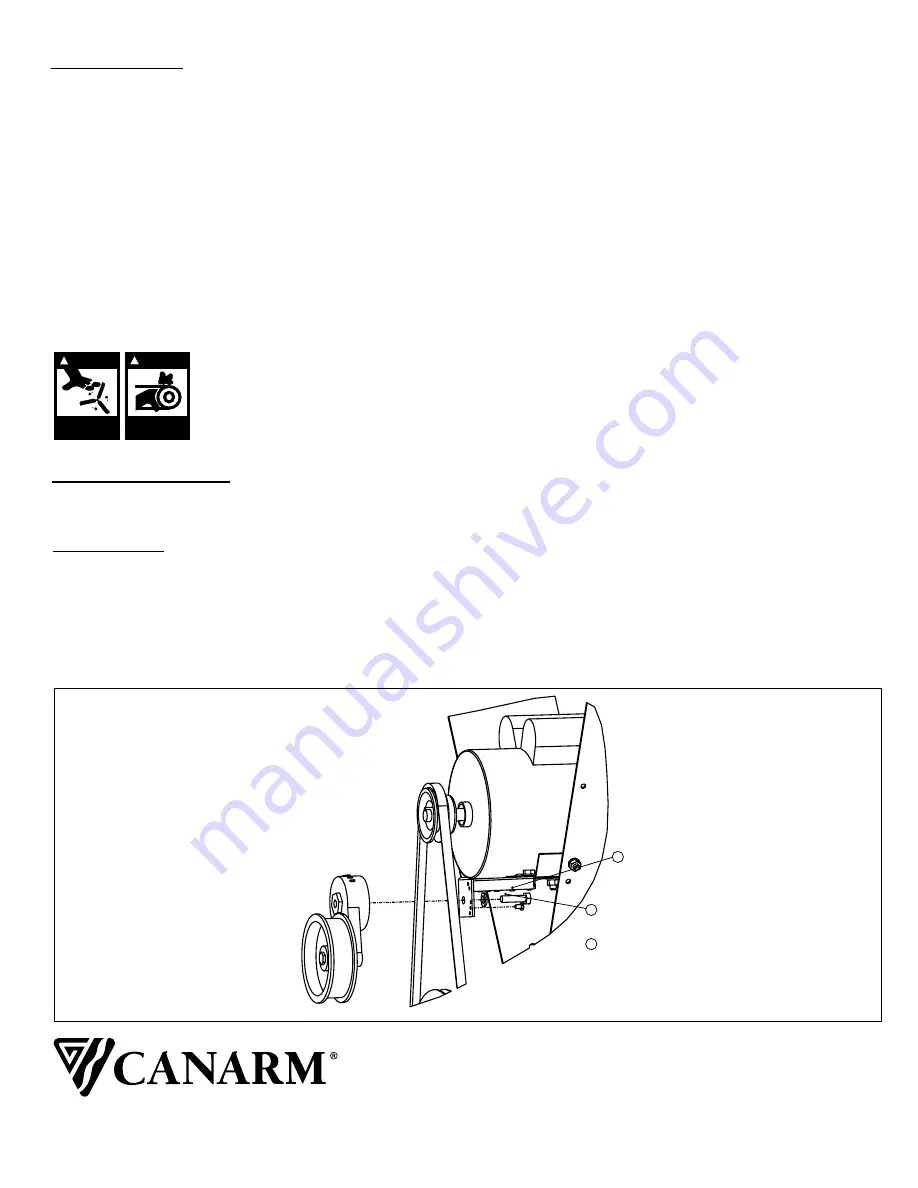

BELT DRIVE FAN

Belt drive fans are equipped with an automatic belt tensioner and cogged v-belt. The rotary tensioner will compensate

for any wear or stretching of the belt. No adjustments should be necessary. Belt will however wear after extensive use.

Fan performance will be sacrificed if worn belt is used. Listen for belt “squeeling” on startup. This would indicate that

the belt requires changing or tightening. Tightening can be done by moving the screw location on the tensioner

bracket. (see figure 3) (Although we recommend replacing the belt).

Lubrication:

Belt drive fans are provided with bearing blocks that are pre-lubricated & sealed. They have a double

contact seal and steel slinger that prevents most contamination. However, since the bearings are to operate in very

damp and dirty conditions, re-lubrication is recommended. The grease fitting of the unit should be carefully cleaned

before use and the grease should be introduced slowly. Under normal conditions, the bearings only need re-lubrication

every 3 years. Nonetheless, we recommend that each bearing receive one pump from a grease gun (or until fresh

grease is pushed out), every time the unit is washed down (especially if detergent is used.)

Note:

Use NLGI2 lithium base grease to ensure compatibility with original grease.

Caution:

Do not use pneumatic grease guns. Slowly introduce grease with manual gun otherwise bearing seals will be

destroyed.

REPLACEMENT PARTS

See attached appendices for replacement parts.

ACCESSORIES

Canarm provides a full line of controls from simple on/off thermostats to sophisticated multiple staging controllers and

PC based controllers. Winter covers are available for colder climates where the fan is shut down for the winter.

Performance enhancing cones are available for 24" to 48" sizes that boosts air moving performance and efficiency by

approximately 8% for PLF48, 10% for PLF36 fans, and 15% for PLF24 fans. Weather Hoods are available for 9” to 24”

models.

WARNING

Moving parts,

disconnect power

before servicing.

!

WARNING

Moving parts,

disconnect power

before servicing.

!

WARNING: Motors are equipped with automatic overload protection and may

restart without warning. Always disconnect power before attempting to service,

or removing shutter

1

Remove bolt

3

Use screw from step 2 as pin location for

tensioner. Reassemble bolt from step 1.

Note:

Remove belt before making adjustments.

CANARM LTD.

CANARM LTEE.

2157 PARKEDALE AVENUE

8500 RUE GRENACHE

BROCKVILLE, ONTARIO K6V 5V6

ANJOU, QUEBEC H1J 2B1

TELEPHONE: (613) 342-5424

TELEPHONE: (514) 353-2255

FAX: 1-800-263-4598

FAX: (514) 353-2522

E-MAIL: agsales@canarm.ca

E-MAIL: agsales@canarm.ca

Figure 3

Adjusting Belt Tensioner

M0017 - Rev. 5 - Rev Date: 22/04/03

Page 5 of 5

2

Change screw hole placement. Moving screw

towards belt will increase tension.