23

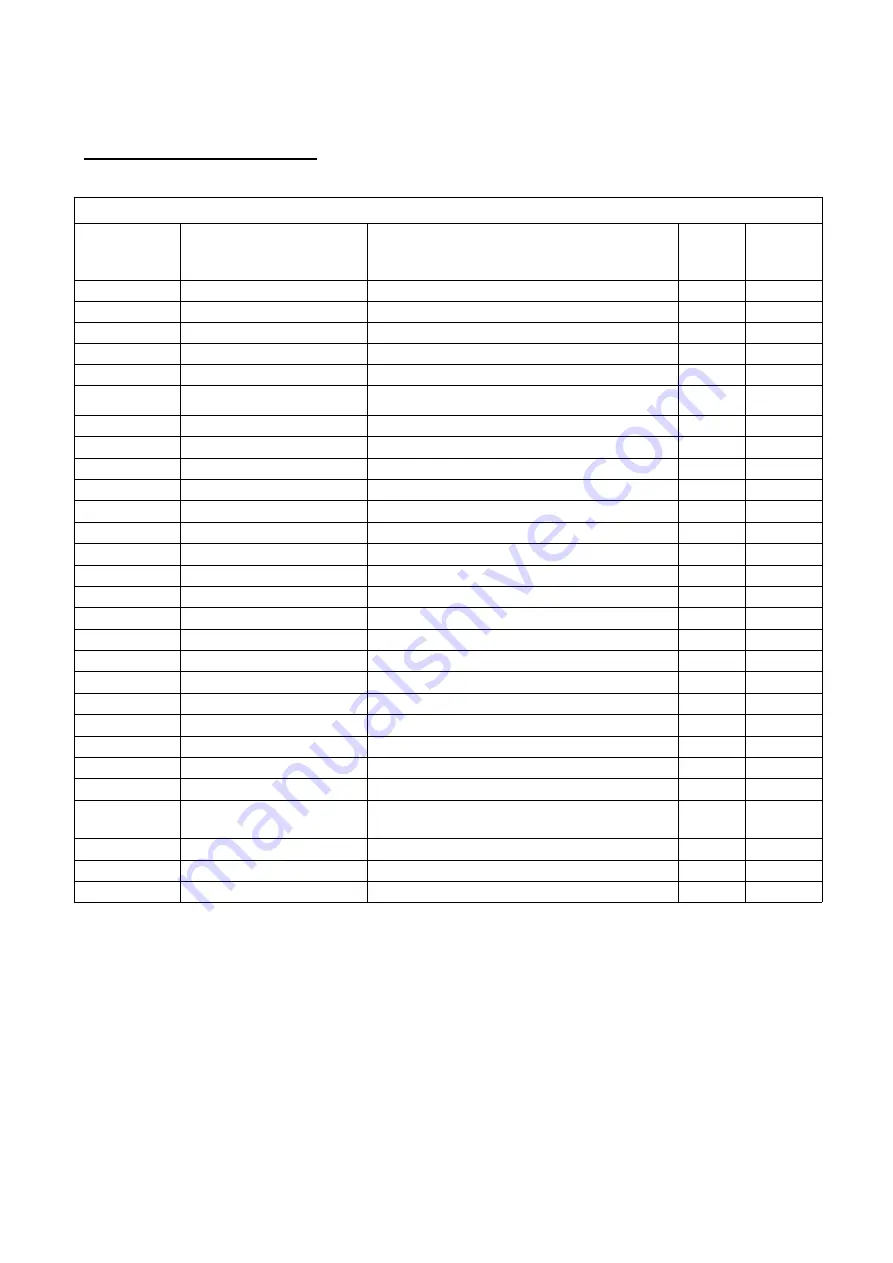

Power Head Parts List

785HE POWER HEAD (DOWNFLOW)

Replacement

Part Number MFG Part Number

Part Description

DWG # Quantity

60010574

Screw-ST3.5X13

B01

10

60010673

Screw-ST2.9X10

B02

9

Screw-ST3.5X25

B03

1

BNT85HE Piston Rod Guide Plate

B04

1

60010050

Motor-12v/2rpm

B05

1

97000967

Motor Power Cable

1

60010660

Motor Pin

B06

1

60010573

BNT85HE Mounting Plate

B07

1

92389

BNT85 Drive Gear

B08

1

60010099

Screw-ST2.9X13(Large Washer)

A24

2

60010100

Washer-3x13

B09

1

60095078

BNT85 Main Gear

B10

1

60095093

BNT185 Housing

B11

1

92392

BNT85HE Brine Gear(Downflow)

B12

1

60010672

Magnet(3×2.7)

B13

1

Washer-4x12

B14

1

60010661

Screw-ST4.2X12(Large Washer)

B15

1

60095082

BNT85HE Piston Rod

A04

1

60095622

Screw-ST3.5X16

B16

1

60010179

BNT85HE Rear Main Pcb(Downflow)

B17

1

60010115

CABLE METER

1

Meter Strain Rlief

1

60010124

Power Cable

1

Power Strain Rlief

1

60095099

Wire Rope-3×100

2

60010180-1.7A

BNT85HE Display (Downflow)

B18

1

60010240

BNT85 Wiring Harness

1

60095081

BNT85 Cover

B19

1

Summary of Contents for 785 HIMTLC PLUS Series

Page 9: ...9 Installation...

Page 16: ...16 Main Repair Parts Connectors A A A B D F E A C 21363...

Page 17: ...17...

Page 21: ...21...

Page 22: ...22 Power Head Exploded View...

Page 24: ...24 Trouble Shooting...