RS02250/0717/CD

26

www.cdtechno.com

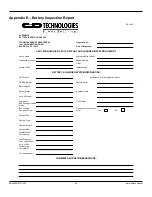

Figure A5

Floor Anchoring

Floor loading and anchoring requirements

are the responsibility of the user/installer

and all applicable building codes and

regulations must be followed. C&D

provides connection drawings, weights,

dimensions, and floor loading information

on our system drawings for reference

which is supplied with every shipment.

Anchor bolts are the responsibility of the

user/installer and are not supplied with the

order.

1. Where floor anchoring is required, place

base assembly into position and mark

the anchor locations using the base as a

template (See Figure A5 & A6).

2. Four

13/16” [20.6mm] holes are

provided in the system base for floor

anchoring.

3. Install floor anchors and reposition base

onto anchors (See Figure A6).

4. Install anchor hardware and verify top

surface of base assembly is level in both

axes, if necessary install shims to level

base.

5. Once base assembly is level, torque

anchors to proper rating based on

manufactures specification (See Figure

A7).

6. A level base is particularly important

for the stability and safety of high,

narrow stacks.

If tool clearance is an issue rear anchors can be accessed

using a

standard 3/8” extension as shown.

Figure A6

Figure A7