RS02250/0717/CD

31

www.cdtechno.com

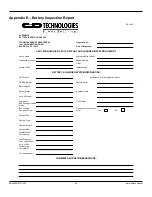

Appendix B - Terminal Connections

1. Remove any remaining factory-applied grease coating from the terminals with a

dry cloth.

2. Lightly brush the terminal, cable lug, terminal plates (optional) and contact surfaces with a plastic

brush or medium gr

ade Scotch Brite™.

3. Coat all electrical surfaces with NO-OX-ID grease. (Optional: Use heat gun or hot plate to melt and

then apply the NO-OX-ID grease, no open flames).

4. (Optional) - Re-flow excess NO-OX-ID with heat gun and wipe excess.

5. Install hardware and torque to 110 in. lb. (12.4 N-m).

6. Wash hands after working with lead.

Reworking Terminal Connections:

If a terminal connection needs to be reworked (for any reason)

follow the below steps:

Once the battery string has been removed from service using properly insulated tools and all appropriate

battery safety methods remove the suspect connection(s).

1. Remove any existing grease using a dry cloth.

2. With a neutralizing solution consisting of one-pound baking soda mixed with one

gallon of water, wipe the cover and terminal seal area with a cloth moistened with the neutralizing

solution. Do not allow the neutralizing solution to enter the cell. Rinse with clear water and dry

thoroughly.

3. Lightly brush the terminal, cable lug or terminal plate contact surfaces with a plastic brush or

medium grade Scotch Brite™, removing any oxidized or corroded areas.

Note: Liberty 2V batteries terminals, buss bars, cable lugs and terminal plates are made of copper and

have a thin layer of tin. Once the terminal connection is coated with protective NO-OX-ID type grease,

any “exposed”, or “un-tined” areas, no matter if from the factory or due to over brushing, will be protected

from oxidation by the grease and not require reworking. Optional: preheat the NO-OX-ID type grease and

apply warm. After working with any lead component, wash your hands.

4. Coat all electrical surfaces with NO-OX-ID grease. (Optional: Use heat gun or hot plate to melt

and then apply the NO-OX-ID grease, no open flames).

5. (Optional) - Re-flow excess NO-OX-ID grease with heat gun and wipe excess.

Re-Install hardware and torque to 110 in. lb. (12.4 N-m) and measure connection resistance.

If still > +10% consult C&D.