18

USER’S INSTRUCTIONS

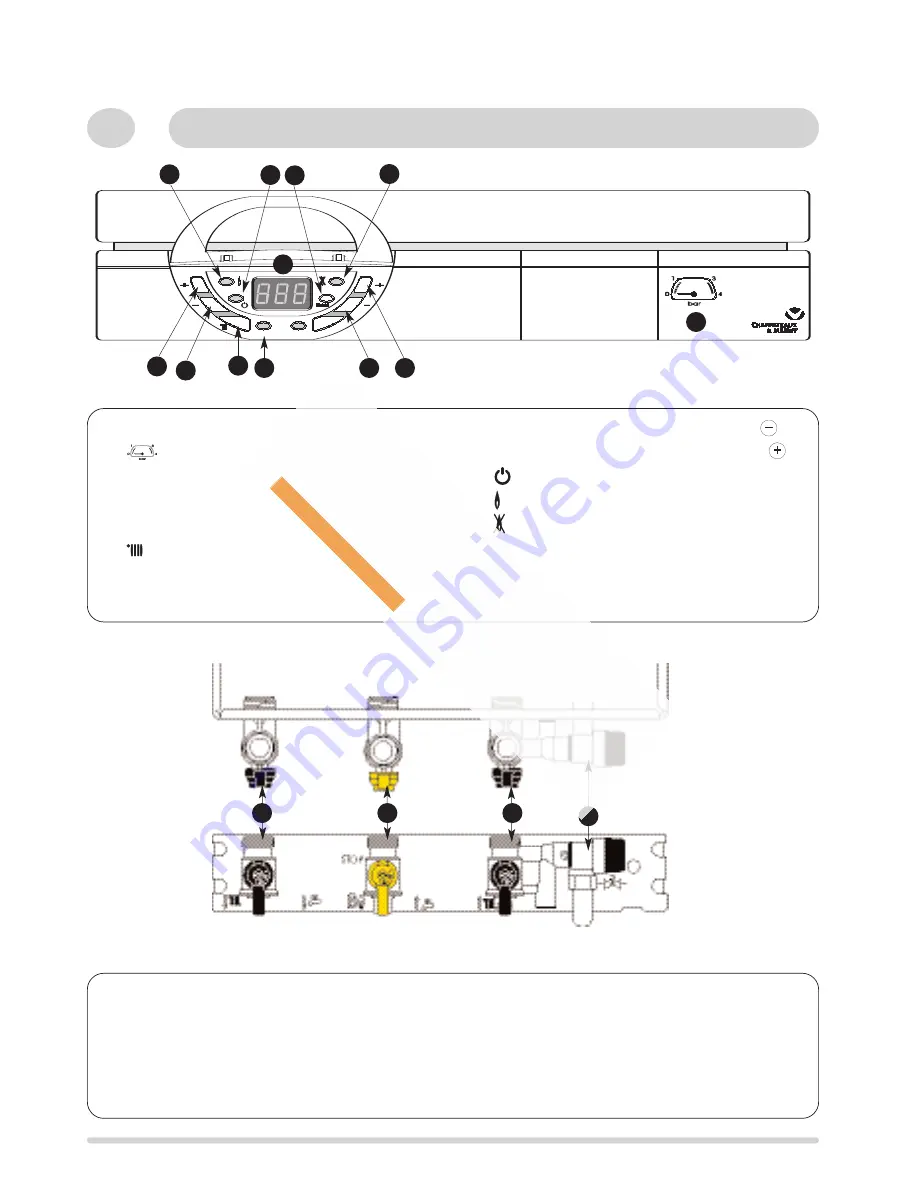

Control panel (Fig. 19)

16.- Pressure

gauge

24.- Display temperature adjustment

27.- Setting key

28.- Setting key

29.-

Switch for Central Heating mode

30.- Green indicator Central Heating

31.- Key to reduce the Central Heating temperature

32.- Key to increase the Central Heating temperature

33.-

Green indicator - Power ON

34.-

Orange indicator - Burner ON

35.-

Red indicator - Lock out / flame failure

36.- Reset button

12

Connecting bracket Taps shown in Open position(fig. 21)

37 : Central heating flow isolating valve

39 : Gas service tap

41 : Central heating return isolating valve

43 : Central heating pressure relief valve

16

24

29 30

27

28

31

32

34

35

36

33

Fig. 19

Fig. 20

37

41

39

43

Control Panel