7

5

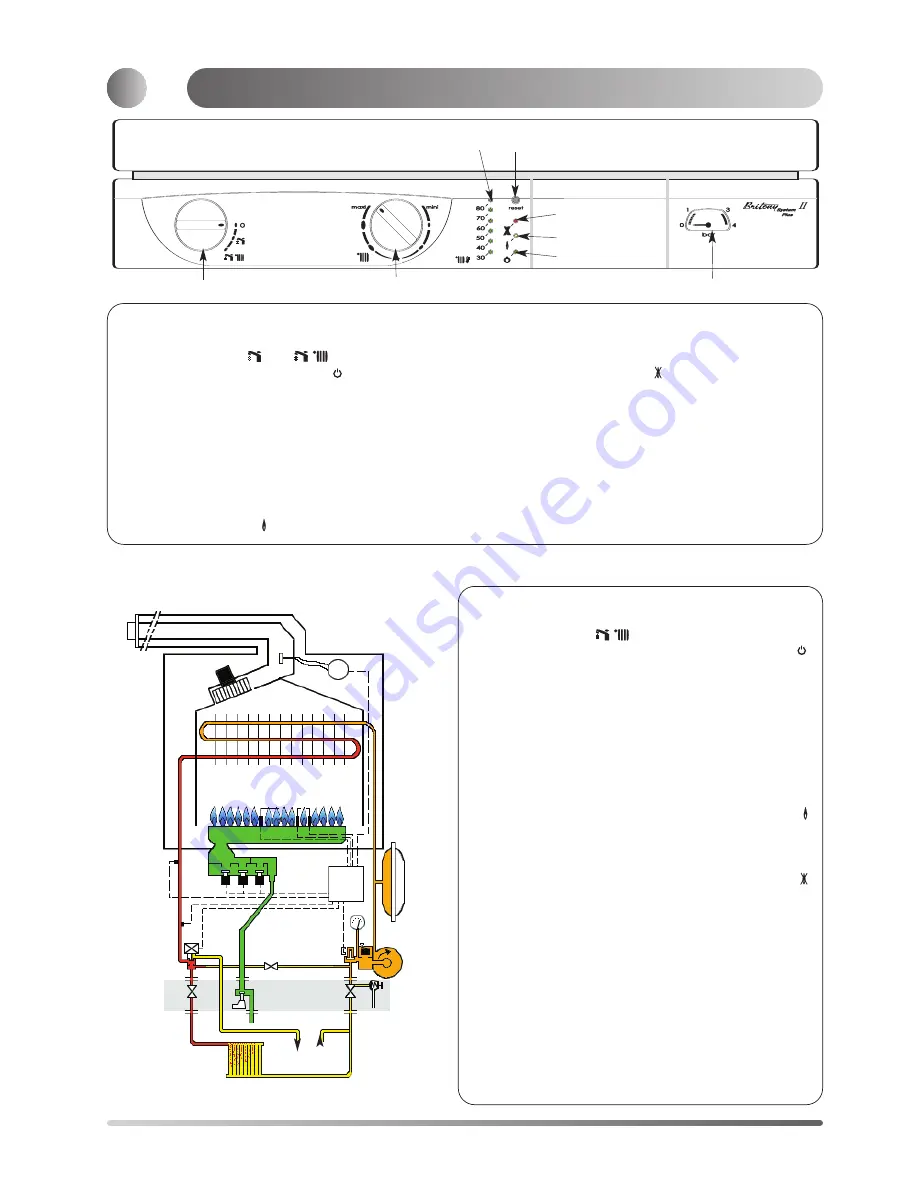

Fig. 7

Domestic Hot Water Mode

To be able to supply hot water, the selector switch (15 fig.

6) must be in either in

or

position. This will be

confirmed by the green indicator light

(18 fig. 6).

When the cylinder thermostat is calling for heat, it switches

the 3 way valve

g (fig. 7) to hot water position. Then the

hot water from the primary circuit is diverted through the

cylinder coil to heat DHW.

The first stage solenoid

a (fig. 7) and safety solenoid

c (fig. 7) open together to allow gas to the burner.

The ignition sequence begins and a continuous high speed

spark ignites the gas. As soon as a flame is detected the

orange indicator bulb

(19 fig. 6) will light and the

second

stage solenoid

b (fig. 7) opens to allow the full gas rate.

If a flame is not detected, after 8 seconds, the security

solenoid closes and shuts off the gas.

The red lockout indicator bulb

(20 fig. 6) will light.

The hot water flow temperature is controlled by the primary

circuit control thermistor

e (fig. 7).

When the cylinder thermostat is satisfied, the burner is

extinguished and the pump stops.

The boiler will now stay in the hot water mode for three

minutes.

Priority will be given to a demand for reheating the

cylinder.

C

15

16

18

20

17

21

19

22

a

b c

e

Fig. 6

Central Heating Mode

To be able to supply central heating, the selector switch

(15 fig. 6) must be in

position. This will be confirmed

by the green indicator light

(18 fig. 6)

When there is a demand for heating (either from the room

thermostat or the external programmer) and the boiler

temperature control is calling for heat. The pump starts and

at a flow rate of 4 ltr/min the central heating flow switch

operates allowing the ignition sequence to begin. The first

stage solenoid

a (fig. 7) and safety solenoid c (fig. 7) open

together to allow gas to the burner. The ignition sequence

begins and a continuous high speed spark ignites the gas.

As soon as a flame is detected the orange indicator bulb

(19 fig. 6) will light. After 45 seconds the second stage

solenoid

b (fig. 7) opens to allow the full gas rate. If a flame

is not detected, after 8 seconds, the security solenoid closes

and shuts off the gas. The red lockout indicator bulb

(20 fig. 6) will light.

The central heating flow temperature is controlled by the

central heating control thermistor

e (fig. 7). The boiler has

been designed to minimise cycling and will not attempt to

relight for at least 3 minutes after the boiler thermostat has

been satisfied (this «TAC delay» can be set to 30 seconds if

required, see maintenance and service guide). When the

room thermostat is satisfied the burner will switch off and the

pump will remain running for a further 3 minutes.

NB

It is possible to override the TAC delay by pressing the

cylinder

coil

g

Operation

Summary of Contents for Britony System II Plus 100 Nat

Page 15: ...15 Notes...