16

16

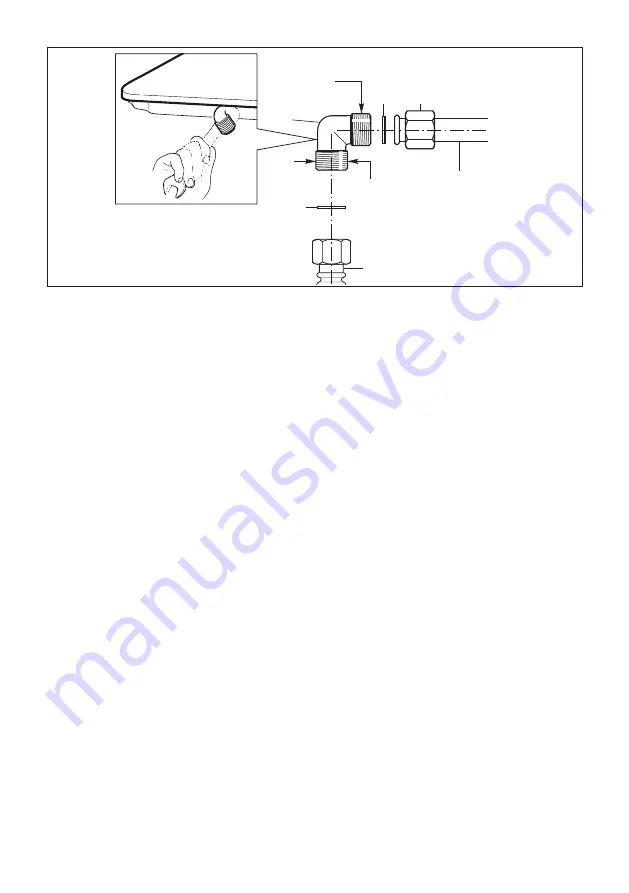

Fig. 2.1

Gasket Floating nut

Gasket

Elbow

ISO 228-1 (male)

1/2” cylindrical

ISO 228-1 (male)

1/2” cylindrical

Rigid pipe or

flexible hose

Appliance

inlet pipe

ADDITIONAL GAS CONNECTION REQUIREMENTS

When connecting the cooktop to the gas supply with rigid pipes or a flexible hose, make

sure that:

•

You use rigid pipes or a flexible hose compliant with applicable local regulations. The

flexible hose shall be of the correct construction for the type of gas being used and of

the correct size to maintain the heat output of the appliance.

•

The connection with rigid metal pipes does not cause stress or pressure to the gas

piping.

•

The flexible hose is not under tension, twisted, kinked, or too tightly bent, neither while

the cooktop is in use nor while it is being connected or disconnected.

•

The flexible hose is not longer than 2000 mm (or refer to applicable local regulations)

and does not come into contact with sharp edges, corners, or moving parts, as these

may cause abrasion. Use a single flexible hose only; never connect the cooktop with

more than one flexible hose.

•

The flexible hose can easily be inspected along its entire length to check its condition;

if it has an expiry date, it should be replaced before that date.

•

If using a flexible hose which is not entirely made of metal, make sure that it does not

come into contact with any part of the cooktop with a surface temperature of 70°C or

above (or refer to applicable local regulations).

•

The rigid pipe or flexible hose is replaced if it shows signs of damage.

•

The flexible hose is not subject to excessive heat by direct exposure to flue products

or by contact with hot surfaces.

•

The socket into which the plug of the flexible hose fit is permanently attached to a firmly

fixed gas installation pipe and is positioned so that the hose hangs freely downwards.

•

The plug of the flexible hose is accessible after installation, so that it can be

disconnected for service or removal.

•

You inform the customer that the rigid pipe or flexible hose should not be subjected to

corrosion by cleaning agents.