Prior to installation, ensure that the local distribution conditions (nature of the gas and

gas pressure) and the adjustment conditions are compatible. The adjustment

conditions for this appliance are stated on the data badge which is fitted on the plinth

panel.

This appliance is not designed to be connected to a combustion products evacuation

device. It must be installed and connected in accordance with current installation

regulations. Particular attention should be given to the relevant requirements

regarding ventilation.

MODEL NUMBERS 10270G Mk2, 10275G Mk2 AND 10278G Mk2

Category I

2H

(GB, IE)

These models are set to burn NATURAL GAS (G20) at 20 mbar ONLY and cannot be

used on any other gas.

MODEL NUMBERS 10271G Mk2 AND 10276G Mk2

Category I

3+

(GB, IE)

These models are set to burn PROPANE GAS (G31) at 37 mbar and BUTANE gas (G30) at

28 - 30 mbar and can not be used on any other gas.

GAS SAFETY (INSTALLATION & USE) REGULATIONS

It is the law that all gas appliances are installed by competent persons in accordance

with the current edition of the above regulations. It is in your interest and that of

safety to ensure compliance with the law.

In the UK, CORGI registered installers work to safe standards of practice.

The cooker must also be installed in accordance with BS 6172: 1990.

Failure to install the cooker correctly could invalidate the warranty liability claims and

could lead to prosecution.

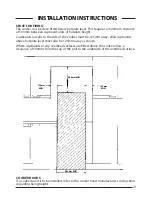

LOCATION

The cooker may be located in a kitchen, kitchen/diner or a bed-sitting room, but not in

a room containing a bath or shower. The cooker must not be installed in a bed-sitting

room of less than 20m

3

.

LPG models must not be installed in a room or internal space below ground level, e.g.

in a basement.

PROVISION FOR VENTILATION

The room containing the cooker should have an air supply in accordance with

BS 5440:Part 2: 1989.

The room must have an opening window or equivalent; some rooms may also require

a permanent vent. If the room has a volume between 5 and 10m

3

, it will require an air

vent of 50 cm

2

effective area unless it has a door which opens directly to outside. If the

room has a volume of less than 5m

3

, it will require an air vent of 100 cm

2

effective area.

If there are other fuel burning appliances in the same room, BS 5440: Part 2: 1989 should

be consulted to determine air vent requirements.

19

INSTALLATION INSTRUCTIONS