16

SuperSix EVO CX/SE OMS

Technical Information

Seat Binder

138671 Rev 1 (3/21)

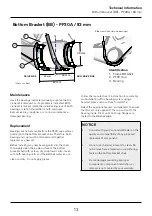

Seat Binder

To service the binder:

1. Remove the seat post, see previous page.

2. Use a 4 mm hex key and turn grub screw (d)

slowly clockwise until the seat binder (1) is

disengaged from the nut base (2).

3. Use the 4 mm hex to push the clamp out

through the seat tube opening.

4. Clean the clamp, inside of the frame with

a clean shop towel wetted with rubbing

alcohol. Take care not to soak the clamp

where the grub screw is assembled.

NOTICE

Solvents will wash out the lubricant and the

assembly will have to be re-greased which will

require disassemby.

5. Check the condition of the seat binder, the

seat post and frame opening. All surfaces

should be smooth. If they are not, the seat

binder (1) should be replaced.

Seat Binder

To re-install the seat binder:

1. Re-apply grease and carbon paste as

indicated on the next page. Take care to not

apply grease to the face of the binder.

2. Returning the seat binder (1) to the frame

opening, using the 4 mm hex to guide it to

the nut base.

3 Turn the grub screw (d) counter-clockwise

until the clamp just touches the nut base

(1), then turn the grub screw (d) clockwise

half a turn. This frees the seat binder (1) to

move out of the way of the seatpost during

installation.

Key points:

•

The internal seat binder system consists of a sliding clamp assembly (1) and a nut base (2)

permanently bonded into the frame.

•

Periodically, the seat binder should be removed and both the seat binder and the frame serviced.