7

134911 Rev 1.

ENGLISH

SYNAPSE - OWNERS MANUAL SUPPLEMENT

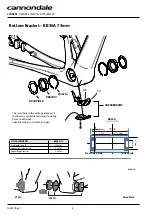

BB Internal Routing

NOTICE

Keep all cables and wires outside the inner bonded

alloy BB shell (1). Do not route cables or wires inside

the inner alloy shell.

Secure all mechanical cables and electronic

wires safely inside the frame, so they cannot

unintentionally enter the inner alloy BB shell

through the access holes (a). The access holes are

only to support installation and removal of parts

through the frame tube easier. Do not permit cables

or wires to unintentionally enter the shell through

these holes.

Mechanical cables and electronic wires that contact

the rotating crank set spindle can cause serious

component damage.

RD

RB

FD

RD

RB

1

(a)

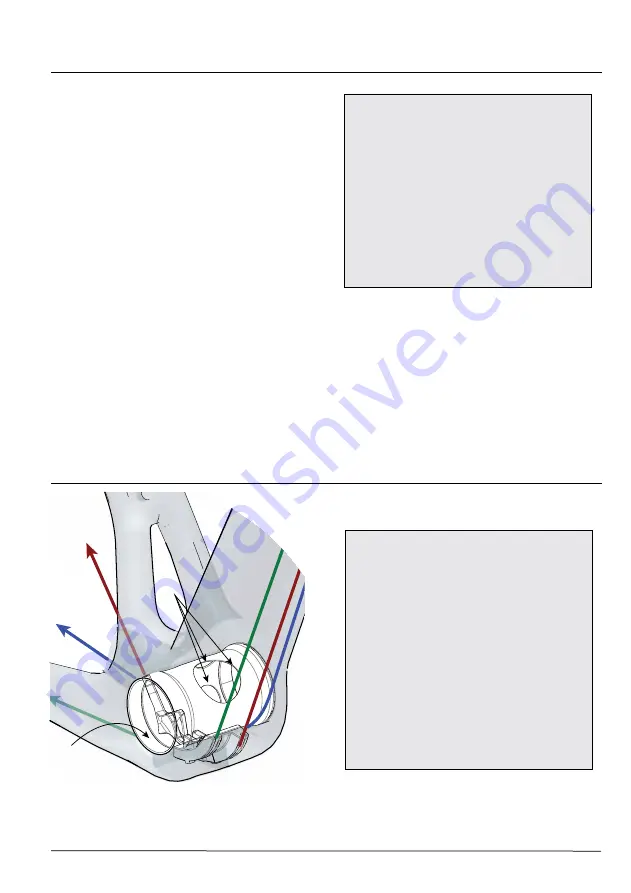

NOTICE

BEARINGS

- Repeated removal and reinstallation

can damage BB shell surfaces resulting in poor

bearing fit.

•

Do not face, mill or machine the bottom

bracket shell for any reason.

•

Repeated removal and reinstallation of BB

components could result in damage to the

shell and is not recommended.

Damage caused by improper installation/

removal is not covered under your warranty.

Bearings

Inspect bearing condition annually (at a minimum)

and anytime the crank set assembly is disassembled

or serviced. With the crank set removed, rotate the

inner bearing race of both bearings; rotation should be

smooth. No play or movement inside the shell. If the

bearing is damaged, replace both bearings with new

ones.

Remove the old bearings with the bearing removal tool

KT011/.

To install bearings, use a headset press and Cannondale

tool

KT010/

. Clean inside of shell apply a high-quality

bicycle bearing grease to the inside surface. Press

bearing one at a time. Press each bearing until seated.

Following installation, apply a light coating of a high-

quality bicycle bearing grease to both sides of each

bearing to help repel moisture.

Do not re-use removed bearings. Install both bearings

as a new set.