3. OPERATION AND TIMING

COPYRIGHT © 2001 CANON INC. CANON CLC1000/1000S/3100 REV.2 MAY 2001 PRINTED IN JAPAN (IMPRIME AU JAPON)

3-114

e. Measuring the Toner by the SALT Sensor

To check the density of toner within the developer, a toner image is formed on the photosensitive drum

after copying operation. This measurement of density is done by the SALT sensor (Figure 3-542) mounted to

the side of the photosensitive drum. A density pattern is formed on the photosensitive drum, and infrared light

is shone against the density pattern to measure the density with reference to the reflected light.

Figure 3-542

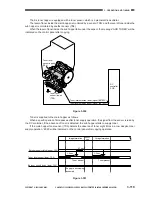

The changes in the LED intensity over time or

caused by changes in ambient temperature are

corrected in the same way as for color toner. Since

the window of the sensor tends to become soiled

with stray toner, correction is made for the dirt on

the window also.

The LED is turned on during last rotation after

copying operation, and the light reflected by the

surface of the photosensitive drum without a

deposit of toner is read. The difference between

the measured value and the initial value is used as

a correction value when computing the density of

the density pattern.

Figure 3-543

Y

M

C

Bk

SALT sensor

SALT sensor

Color toner

density sensor

Transfer belt

SALT sensor

SALT sensor

DC controller

Color toner

density sensor

Color toner

density sensor

Direct intensity/re-

flected intensity

Toner supply signal

Toner supply clutch

CL

Detection of direct light

Mirror

Photosensitive drum

Detection of reflected light

LED

Direct intensity signal

Reflected intensity signal

Summary of Contents for 1000S

Page 12: ......

Page 30: ......

Page 44: ......

Page 86: ......

Page 254: ......

Page 372: ......

Page 374: ......

Page 418: ......

Page 438: ......

Page 442: ......

Page 754: ......

Page 764: ......

Page 766: ......

Page 840: ...0501GR PRINTED IN JAPAN IMPRIME AU JAPON This publication is printed on 100 reprocessed paper ...