3. OPERATION AND TIMING

COPYRIGHT © 2001 CANON INC. CANON CLC1000/1000S/3100 REV.2 MAY 2001 PRINTED IN JAPAN (IMPRIME AU JAPON)

3-174

d.

Polishing Roller

The polishing roller polishes the surface of the transfer belt to prevent adhesion of fixing oil to the

photosensitive drum, particularly in two-sided copying mode, thereby preventing foggy images.

The transfer belt is polished in response to a press on the power switch after having made 5,000 copies

(cumulative), and the operation is continued until the transfer belt has made 30 rotations.

The polishing roller is butted against the transfer belt when the polishing/oil removing motor (M15)

rotates clockwise and the polishing roller solenoid (SL18) turns on, rotating the cam through the control ring

and operating the push-on spring.

The polishing roller is moved away from the transfer belt when the solenoid turns off to move the cam

before it meets the seam.

The polishing roller rotates slightly to change its position of contact against the transfer belt when the

operation of the transfer belt lifter pushes the one-way clutch lever.

If the polishing/oil removing motor rotation speed deviates because of an error, ‘E018’ will be indicated

on the control panel.

Figure 3-642

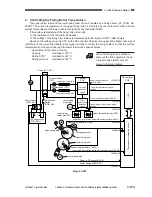

Transfer belt

Polishing/oil removing motor (M15)

Cam

(front of copier)

Polishing roller

Polishing roller solenoid

(SL18)

One-way clutch lever

DC controller PCB

Polishing/oil removing motor

CW rotation drive signal

(M15CW)

Polishing roller solenoid drive signal (SL18D*)

Push-on spring

Transfer belt feeding direction

Control ring

J2218B-7

J2218A-9

Summary of Contents for 1000S

Page 12: ......

Page 30: ......

Page 44: ......

Page 86: ......

Page 254: ......

Page 372: ......

Page 374: ......

Page 418: ......

Page 438: ......

Page 442: ......

Page 754: ......

Page 764: ......

Page 766: ......

Page 840: ...0501GR PRINTED IN JAPAN IMPRIME AU JAPON This publication is printed on 100 reprocessed paper ...