3. OPERATION AND TIMING

COPYRIGHT © 2001 CANON INC. CANON CLC1000/1000S/3100 REV.2 MAY 2001 PRINTED IN JAPAN (IMPRIME AU JAPON)

3-178

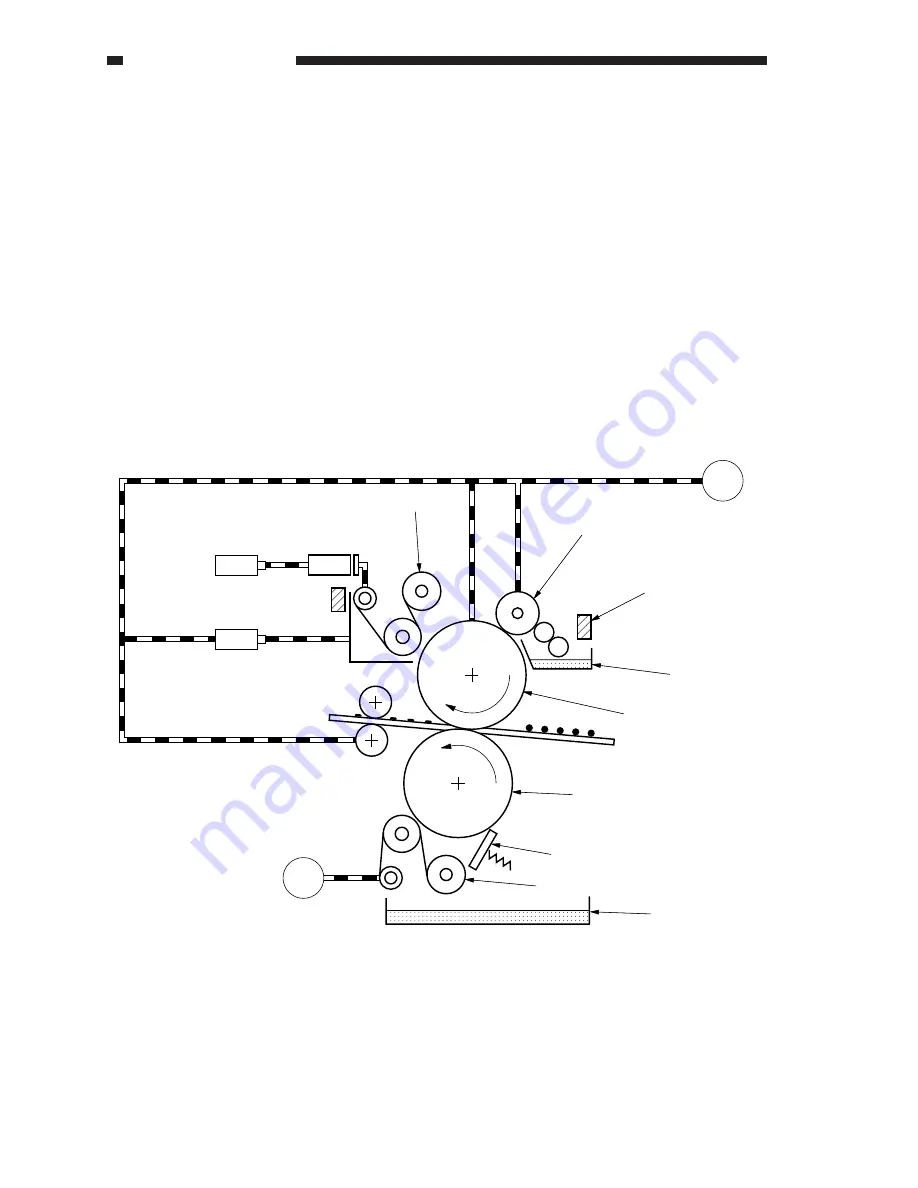

G. Fixing/Delivery Assembly

1. Outline

The following loads are driven by the fixing motor (M9).

• Upper fixing roller

• Lower fixing roller

• Delivery roller

• Oil applying roller

• Upper fixing web (locking)

To ensure proper fixing when making two-sided copies or copying on transparencies or to suit various

copying modes, the CLC1000 controls the fixing speed over six settings.

The upper roller and the lower roller are each equipped with a fixing cleaning web. The upper fixing web

is driven by the upper fixing web take-up solenoid (SL3), and the lower web is driven by the lower fixing web

motor (M30).

In addition, the lower fixing roller is equipped with a spring locking type cleaning blade. The separation

claw used to prevent wrapping of paper round the lower fixing roller is operated to move away from the lower

fixing roller by the drive of the separation claw solenoid (SL15) to prevent damage to the lower fixing roller.

Figure 3-646

M9

Fixing motor

Upper fixing web

take-up solenoid

SL3

SL4

One-way clutch

Upper fixing web

Oil applying roller

Oil level sensor (PS6)

Upper oil pan

Upper fixing roller

Lower fixing roller

Oil removing blade

Lower fixing web

Lower oil pan

Lower fixing web motor

Upper fixing web releasing solenoid

Web length sensor (PS36)

M30

Summary of Contents for 1000S

Page 12: ......

Page 30: ......

Page 44: ......

Page 86: ......

Page 254: ......

Page 372: ......

Page 374: ......

Page 418: ......

Page 438: ......

Page 442: ......

Page 754: ......

Page 764: ......

Page 766: ......

Page 840: ...0501GR PRINTED IN JAPAN IMPRIME AU JAPON This publication is printed on 100 reprocessed paper ...