COPYRIGHT © 2001 CANON INC. CANON CLC1000/1000S/3100 REV.2 MAY 2001 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-7

2. COPYING PROCESS

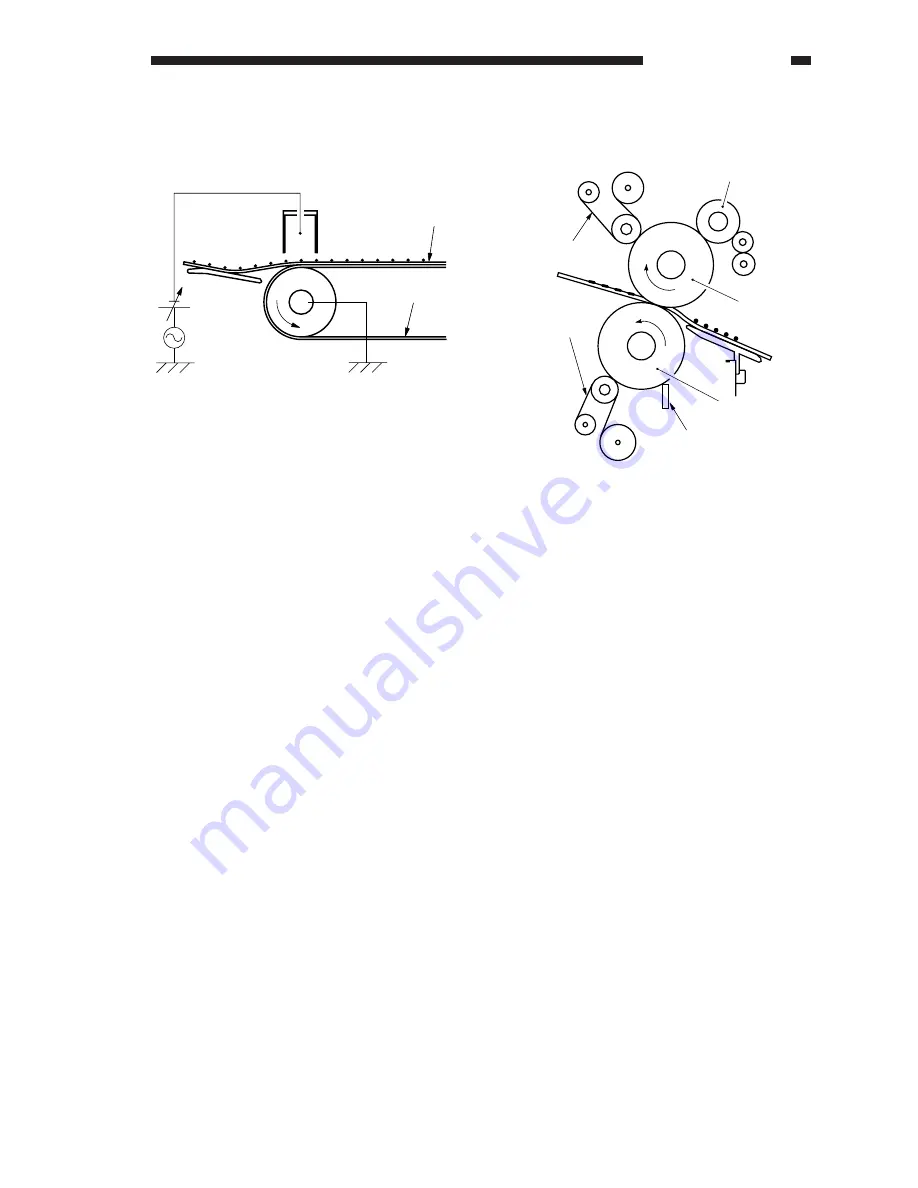

H. Separation (step 6)

Figure 2-111

The CLC1000 separates paper from the

transfer belt using the rigidity of paper (curvature

separation). Since thin paper tends to have little

rigidity, it can wrap around the transfer belt, failing

to separate. To prevent such a problem, the

separation charging assembly applies AC corona

and DC bias, facilitating the separation of paper

from the transfer belt.

Transfer belt

Paper

Separation charging

assembly

I.

Fixing (step 7)

Figure 2-112

Depending on the selected color mode, a

maximum of four transfers takes place before the

paper is forwarded to the fixing assembly.

A pair of fixing rollers move the paper under

pressure and heat, thereby melting the toner

particles (of four colors) to produce as many colors

as needed, reproducing the original images and

fusing them into the fibers of the paper.

To prevent adhesion of toner from paper to the

surfaces of the fixing rollers (offset), the oil

applying roller constantly supplies silicone oil to the

rollers.

The upper fixing roller is cleaned by a cleaning

web, and the lower fixing roller is cleaned by a

cleaning web and a cleaning blade.

Oil applying roller

Upper fixing web

Upper fixing roller

Lower fixing web

Lower fixing roller

Oil removing blade

Summary of Contents for 1000S

Page 12: ......

Page 30: ......

Page 44: ......

Page 86: ......

Page 254: ......

Page 372: ......

Page 374: ......

Page 418: ......

Page 438: ......

Page 442: ......

Page 754: ......

Page 764: ......

Page 766: ......

Page 840: ...0501GR PRINTED IN JAPAN IMPRIME AU JAPON This publication is printed on 100 reprocessed paper ...